Table of Contents

Introduction

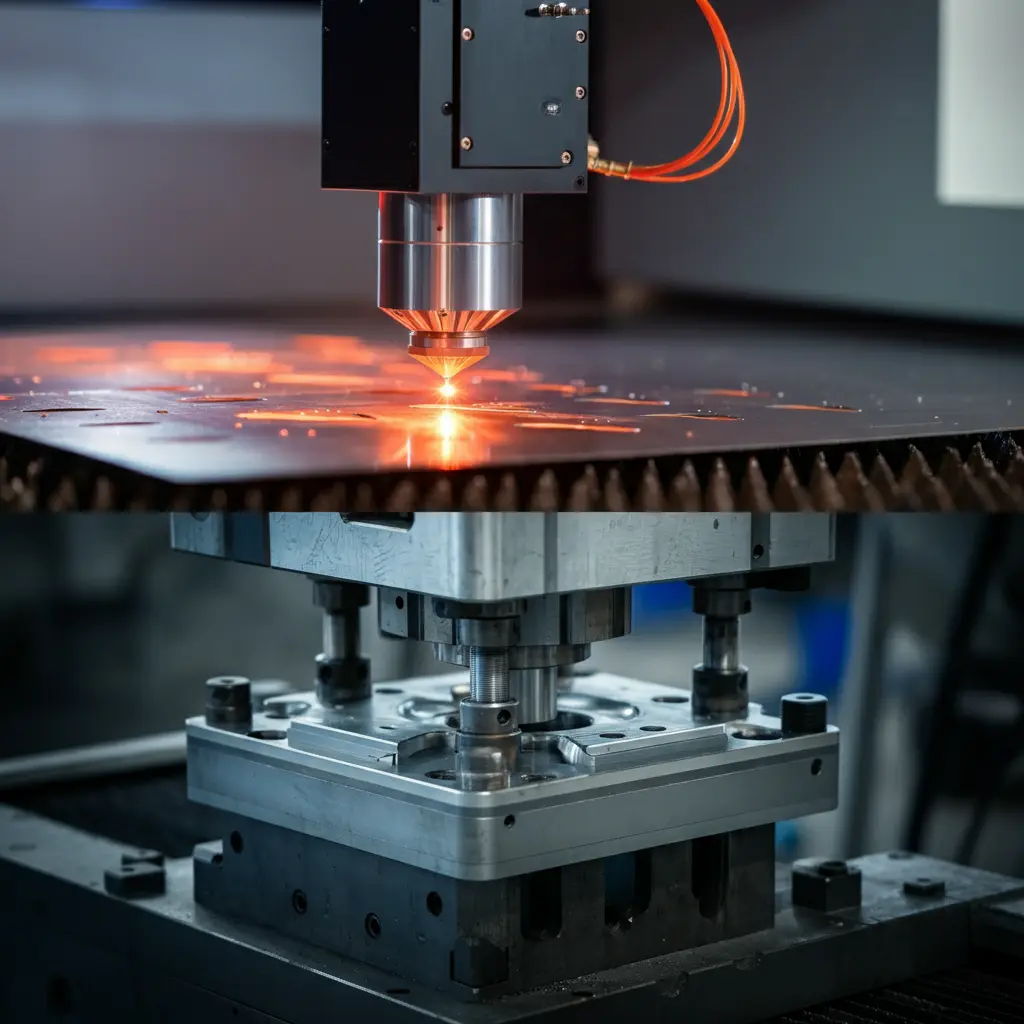

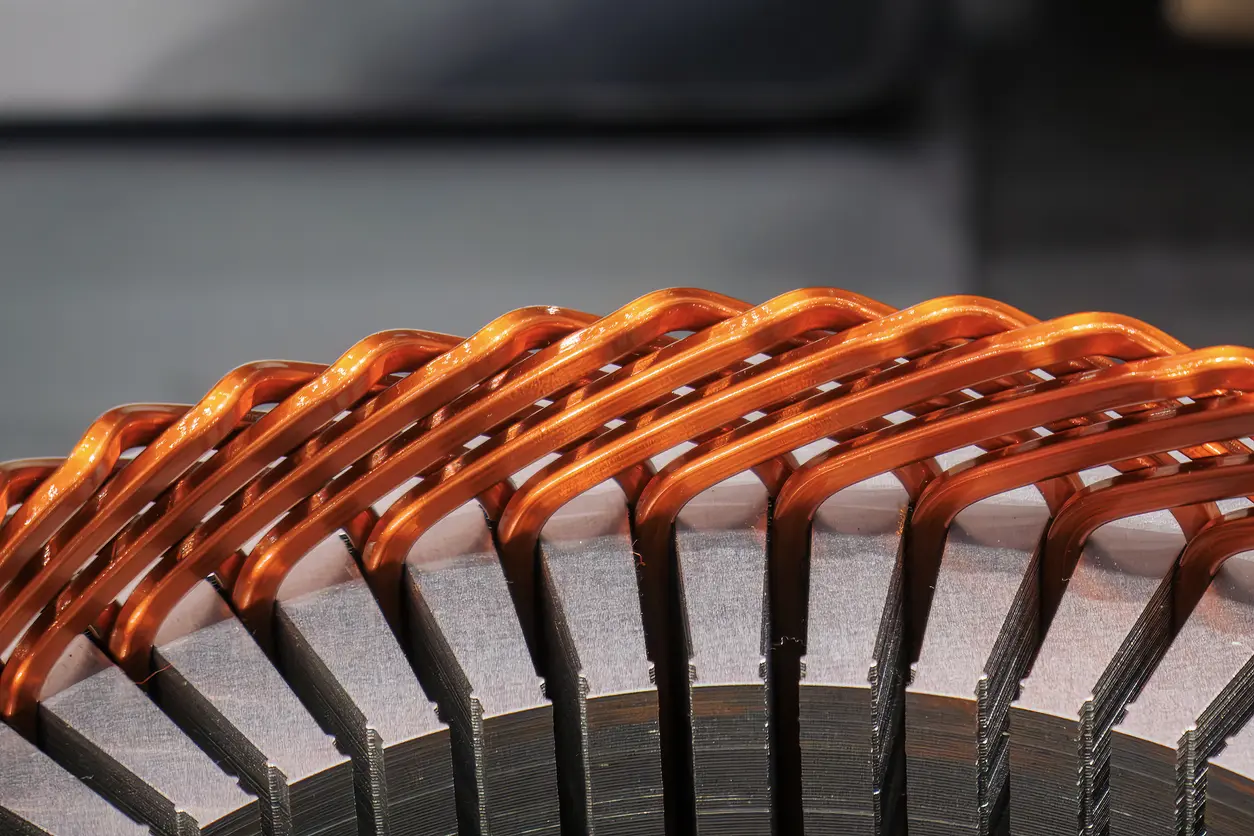

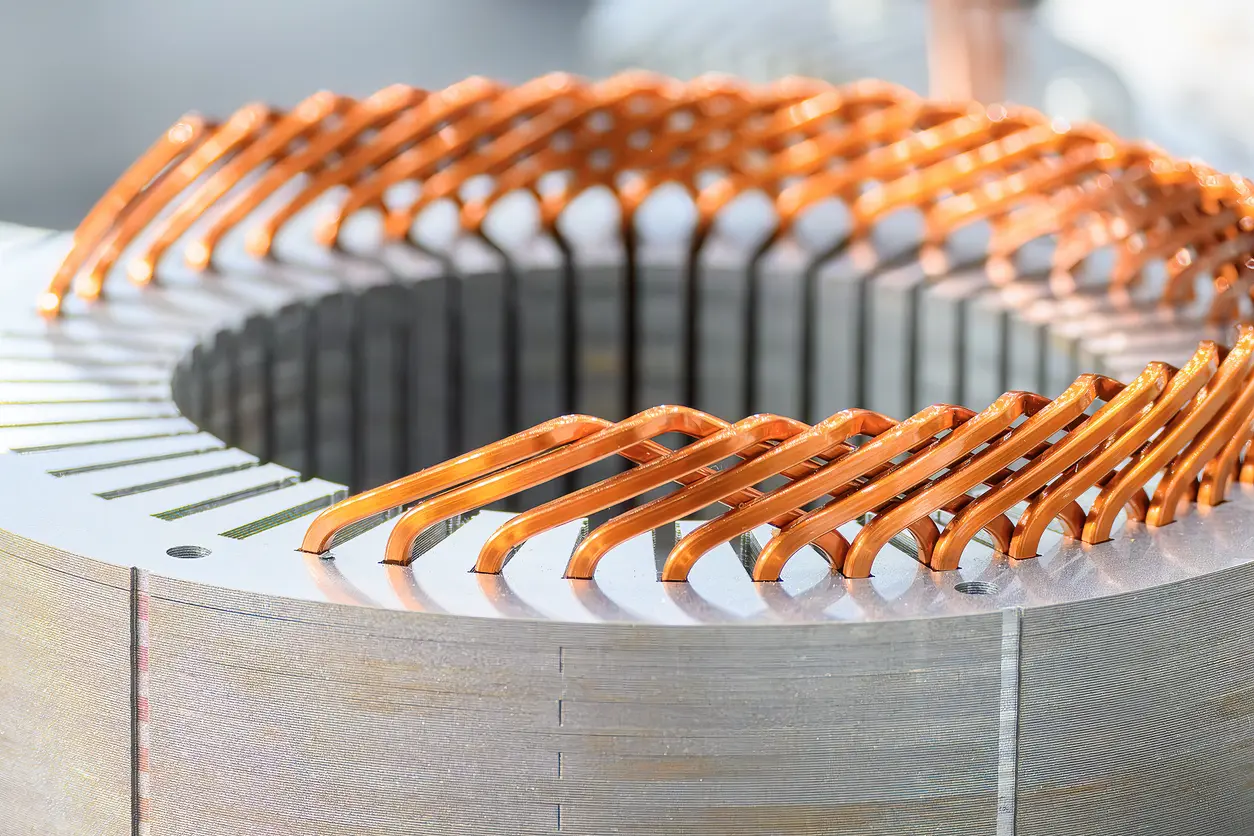

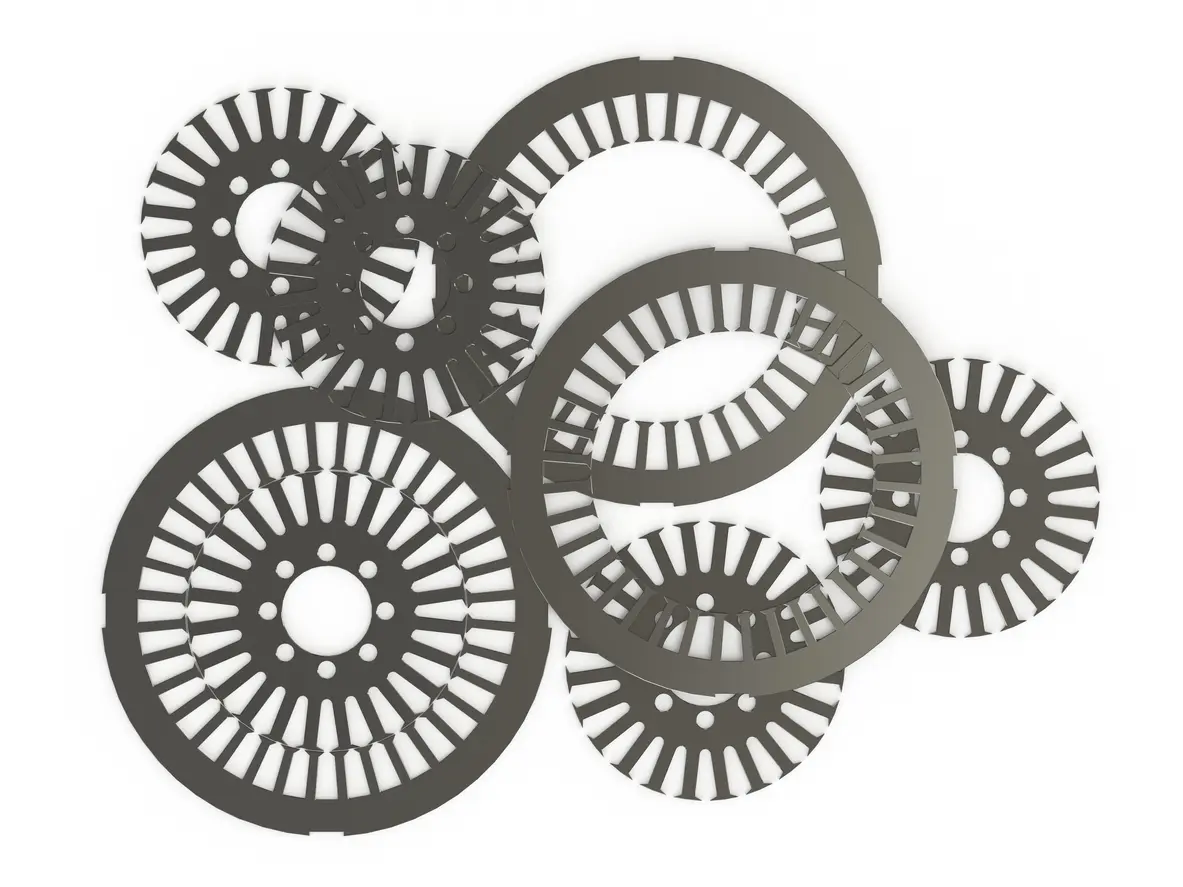

Manufacturing electric motor cores requires a fundamental decision that affects cost, timeline, and performance: selecting the optimal fabrication method for your lamination stack. Two dominant approaches—laser cutting and stamping—serve different phases of product development and production volumes, each offering distinct advantages that align with specific project requirements.

The choice between these manufacturing processes directly impacts your project’s trajectory from initial concept validation through full-scale production. Understanding when to leverage each method’s strengths ensures optimal resource allocation while maintaining the magnetic performance essential for efficient motor operation.

This analysis provides a structured framework for evaluating laser cutting versus stamping based on production volume, design complexity, cost constraints, and project maturity. By examining the technical specifications, economic breakpoints, and material considerations, engineers can make informed decisions that optimize both immediate project needs and long-term production strategy.

Understanding the Fundamentals: Laser Cutting vs. Stamping

What is Lamination Stamping?

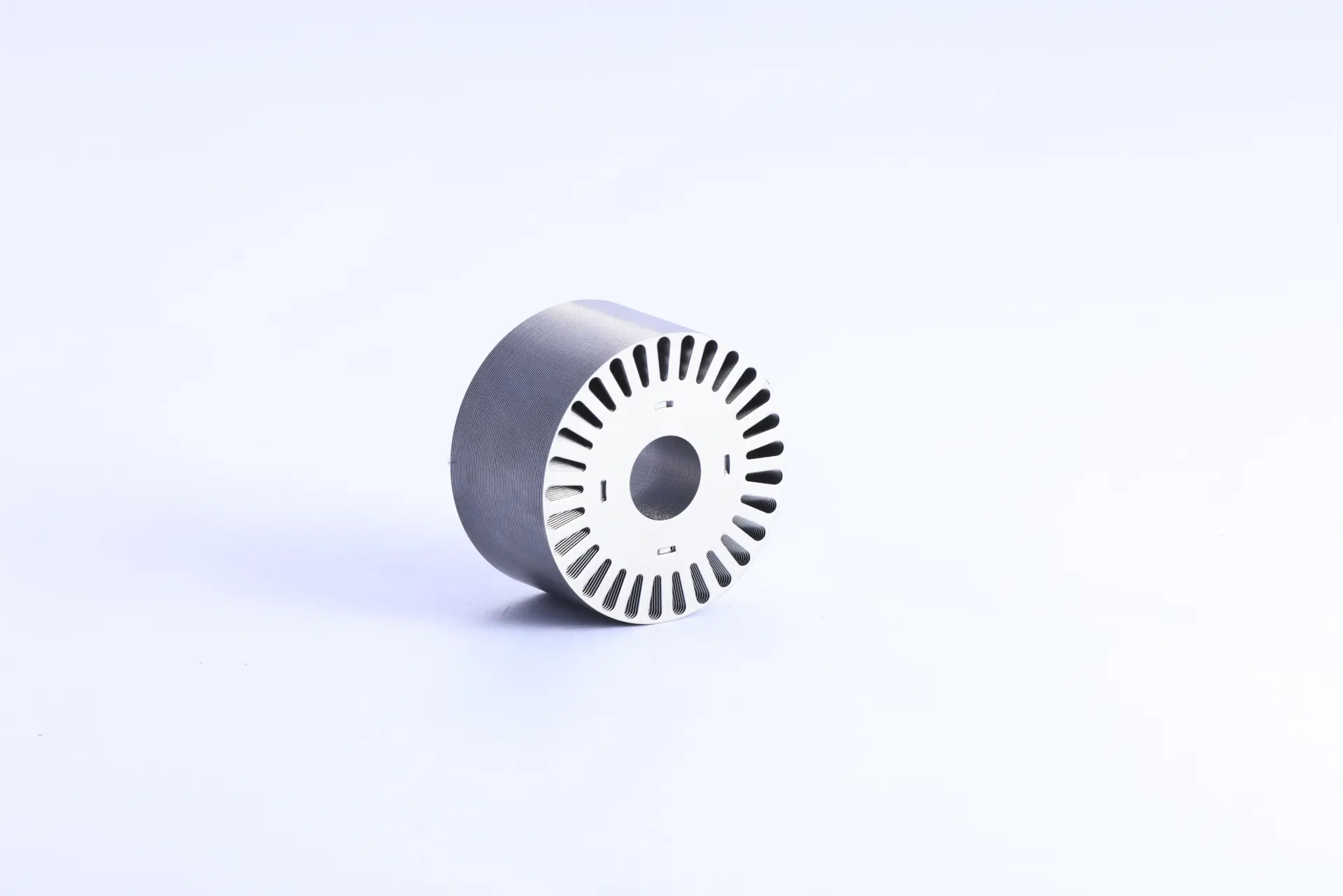

Lamination stamping employs a custom-manufactured die within a high-speed mechanical press to cut precise lamination geometries from continuous electrical steel sheet coils. The process relies on shearing forces applied through hardened steel tooling to achieve consistent part dimensions at production rates exceeding thousands of parts per hour.

The stamping process requires significant upfront tooling investment, with progressive dies typically costing $10,000 to $100,000 or more depending on complexity and precision requirements. However, once tooling is commissioned, the per-unit manufacturing cost drops dramatically, making stamping the preferred method for high-volume production runs where design changes are minimal.

This approach excels in mass production scenarios where a finalized, stable design requires consistent replication across tens of thousands or millions of parts. The mechanical nature of the process ensures repeatability while maximizing material utilization through optimized nesting patterns.

What is Lamination Laser Cutting?

Laser cutting utilizes high-power, CNC-controlled laser systems to precisely cut lamination profiles from electrical steel sheets. The process vaporizes material along programmed cutting paths, creating complex geometries without physical tooling requirements. Modern fiber laser systems achieve cutting speeds and edge quality suitable for motor lamination applications

The absence of tooling costs makes laser cutting immediately accessible for prototype development and low-volume production. Design modifications require only CAD file updates and programming changes, enabling rapid iteration cycles essential during product development phases.

Laser cutting systems excel in applications requiring design flexibility, quick turnaround times, and moderate production volumes. The process accommodates complex geometries and tight tolerances while maintaining consistent edge quality across varying material thicknesses commonly used in motor lamination applications.

Head-to-Head: A Comparative Analysis

At-a-Glance Comparison

| Feature | Laser Cutting | Stamping |

|---|---|---|

| Tooling Cost | None | High ($10,000 – $100,000+) |

| Per-Unit Cost (Low Vol.) | Moderate | Very High (due to tooling) |

| Per-Unit Cost (High Vol.) | High | Very Low |

| Lead Time (Prototype) | Fast (Days) | Slow (Weeks/Months) |

| Design Flexibility | Excellent (Easy CAD changes) | Poor (Requires new tooling) |

| Production Speed | Slow (Parts per minute) | Extremely Fast (Strokes/min) |

| Material Utilization | Good | Excellent (with nesting) |

| Edge Quality | Good, depends on handling | Good, but can have burrs |

| Material Integrity | Potential for Heat Affected Zone | Potential for mechanical stress |

The comparative analysis reveals complementary strengths rather than direct competition. Laser cutting provides immediate access and design freedom, while stamping delivers unmatched efficiency at volume. The selection criteria shift based on project phase and production requirements.

The Break-Even Point: A Cost Analysis

The economic crossover point occurs where stamping’s total cost (tooling plus parts) equals laser cutting’s cumulative part costs. This break-even analysis determines the optimal transition point from prototype to production manufacturing methods.

Example Cost Analysis

Assumptions: Laser Cut Part = $4.50; Stamped Part = $0.30; Stamping Die Cost = $40,000

| Quantity | Total Laser Cutting Cost | Total Stamping Cost | More Cost-Effective |

|---|---|---|---|

| 100 | $450 | $40,030 | Laser Cutting |

| 1,000 | $4,500 | $40,300 | Laser Cutting |

| 5,000 | $22,500 | $41,500 | Laser Cutting |

| 9,524 (Break-even) | $42,858 | $42,857 | Break-even Point |

| 20,000 | $90,000 | $46,000 | Stamping |

| 100,000 | $450,000 | $70,000 | Stamping |

The break-even analysis demonstrates that projects requiring fewer than approximately 10,000 parts favor laser cutting, while higher volumes justify stamping tooling investment. These calculations must account for project-specific variables including part complexity, material thickness, and quality requirements.

Technical Considerations and Material Integrity

Material Integrity and Motor Performance

Heat Affected Zone (HAZ) represents a primary consideration in laser cutting applications. The thermal cutting process creates a narrow zone along cut edges where elevated temperatures temporarily alter the electrical steel’s magnetic properties. For standard motor applications, this effect remains negligible, but ultra-high efficiency designs may require HAZ evaluation.

Mechanical stress induced during the stamping process can similarly impact magnetic performance at lamination edges. The shearing action creates localized stress concentrations that may influence magnetic domain alignment. Stress-relief annealing serves as a common post-processing step for performance-critical stamped laminations such as precision medical devices.

Industry standards such as ASTM A976 provide standardized methods for measuring magnetic property variations in electrical steels, establishing the technical foundation for evaluating material integrity across manufacturing processes.

Technical Specifications Comparison

| Specification | Laser Cutting | Stamping |

|---|---|---|

| Typical Tolerance | ±0.025 mm | ±0.02 mm |

| Burr Height (Typical) | < 5 microns | < 12 microns (can vary) |

| Min. Feature Size | ~0.5 x material thickness | ~1.0 x material thickness |

| Post-Processing | Often none required | Deburring/Annealing often needed |

The technical specifications reveal subtle differences in achievable precision and surface quality. Laser cutting typically produces superior edge finish with minimal burr formation (under well handling condition), while stamping may require additional processing to achieve comparable results.

Production Engineer’s Perspective

Manufacturing experience reveals distinct phases where each process provides optimal value. During development phases, laser cutting enables rapid design validation through quick iteration cycles. Multiple rotor or stator geometries can be evaluated within weeks rather than months required for tooling development.

The transition to stamping becomes compelling when design validation concludes and production forecasts exceed break-even thresholds. One client successfully tested four different stator configurations using laser cutting and EDM-cutting within a single month, ultimately selecting the optimal design for progressive-die stamping tooling once production volume projections reached 50,000 units annually.

The expertise lies in recognizing the precise transition point—too early, and tooling costs burden projects unnecessarily; too late, and per-unit costs compromise profitability. This decision requires balancing design maturity, volume forecasts, and timeline constraints against cost optimization objectives.

Frequently Asked Questions (FAQs)

What is the most common reason to choose laser cutting for production parts?

The most prevalent applications involve low-to-medium volume production runs (typically under 10,000 parts or fewer), products with abbreviated lifecycle expectations, or designs anticipating updates where retooling costs would prove prohibitive. Specialty medical device motors exemplify this category, requiring precision but operating in limited market volumes.

Does the burr on stamped parts affect motor performance?

Excessive burring can compromise the insulation integrity between laminations, creating electrical shorts that increase eddy current losses and reduce motor efficiency. This phenomenon explains why deburring and precise tooling maintenance represent a critical quality control step in stamping operations, particularly for high-performance motor applications.

Can you prototype with stamping?

Simple-die stamping method can meet this criteria. While temporary or “Simple-Die” tooling enables prototype stamping, the approach generally lacks cost-effectiveness compared to laser cutting or wire-EDM cutting. Extended lead times and elevated costs make stamping impractical for early-stage design validation requiring multiple iterations and rapid feedback cycles.

Making the Strategic Manufacturing Decision

The fundamental choice between laser cutting and stamping reflects project maturity and volume requirements rather than technical superiority. Laser cutting provides essential flexibility and speed during development phases and low-volume production scenarios, while stamping delivers unmatched cost-efficiency and production rates for high-volume applications.

Strategic decision-making requires honest assessment of current production volumes, budget constraints, and design stability. Projects in active development benefit from laser cutting’s adaptability, while mature designs with confirmed volume projections justify stamping investment.

For those requiring expert support or tailored solutions, explore custom motor lamination services to ensure your manufacturing approach aligns with your project’s unique needs.

Ready to discuss your motor core manufacturing requirements? Contact our engineering team for a comprehensive analysis tailored to your project’s specific volume, timeline, and performance objectives.