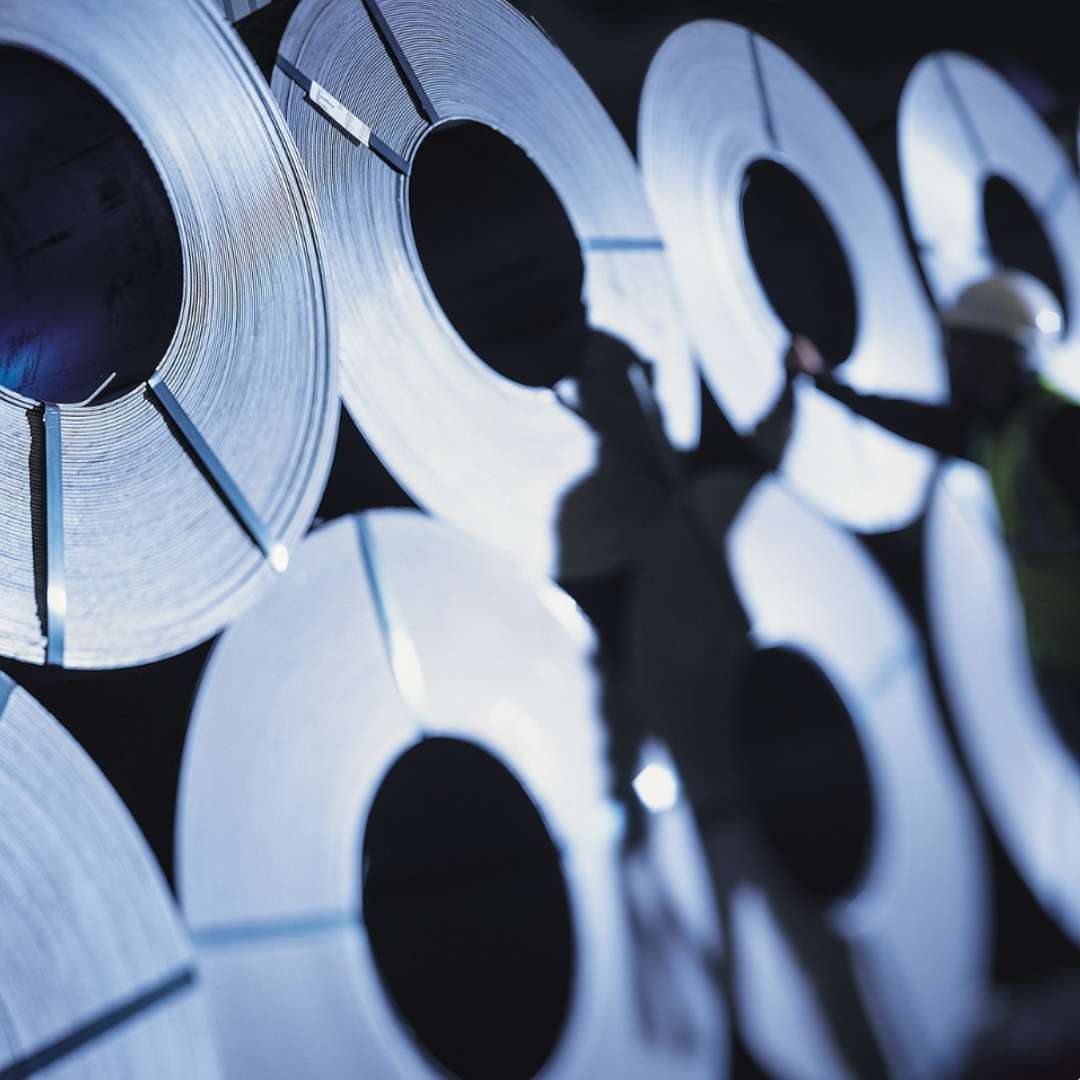

Premium Electrical Steel: Optimized for High-Performance Electromagnetic Applications.

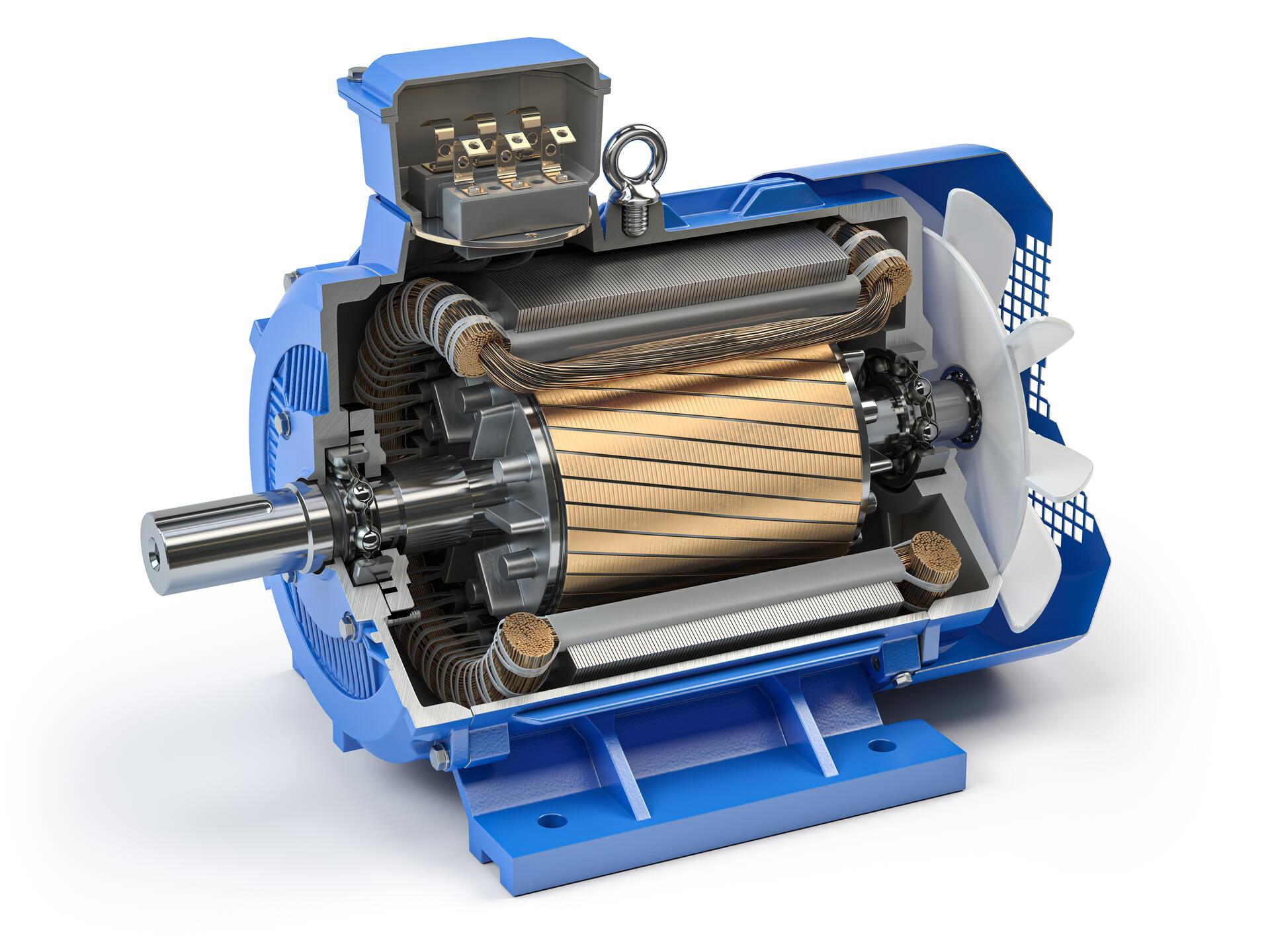

Generally offer lower core losses and higher efficiency, but may be more expensive and require specialized handling.

Provides reduced core losses and improved efficiency and has higher magnetic flux density compared to electrical steel.

Different motor core types and sizes have specific performance requirements.

Selecting materials that prioritize energy efficiency can enhance overall motor performance.

Material selection should align with budget constraints while meeting performance needs.