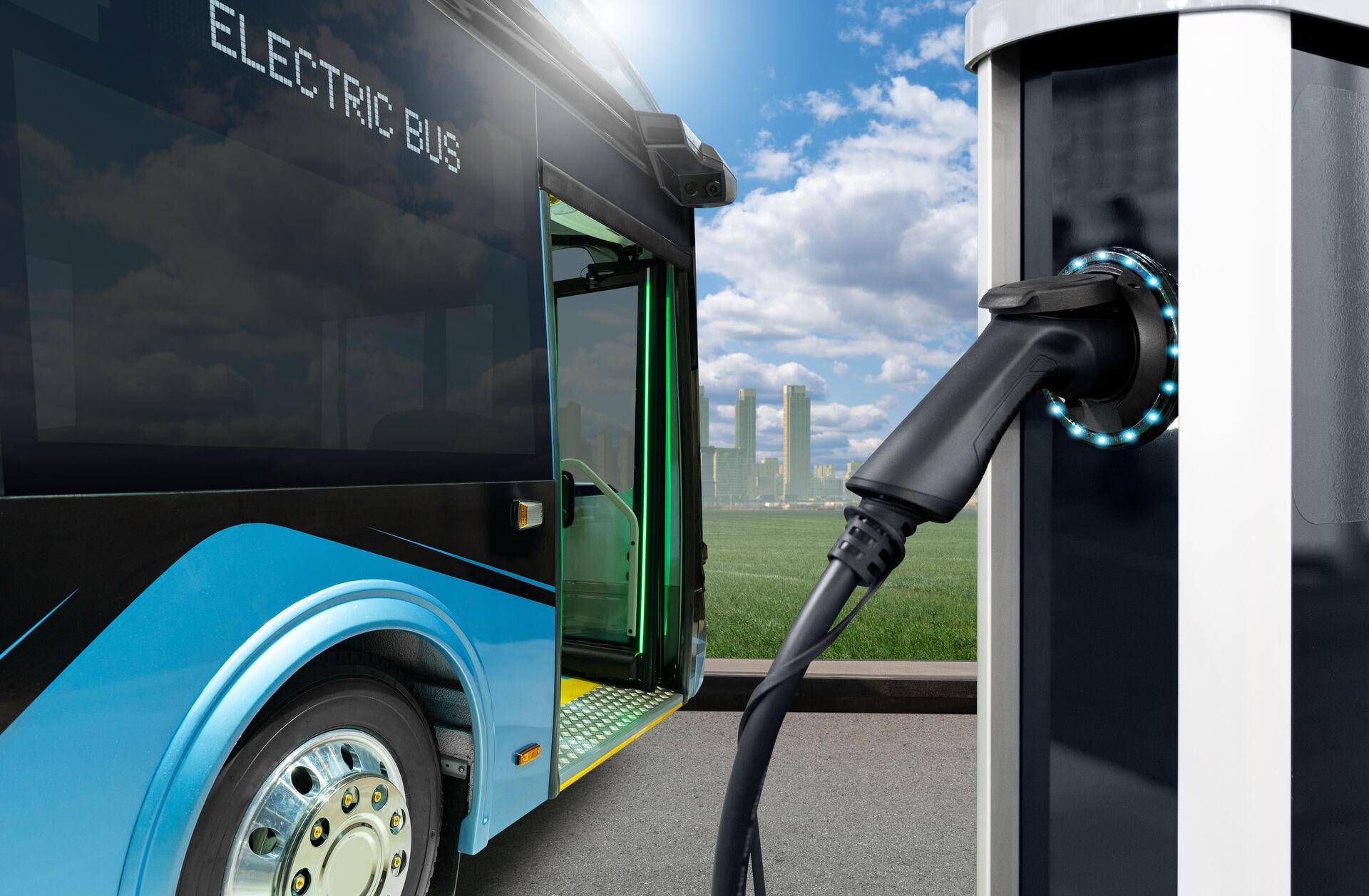

High-Power Electric Bus Motor Core Laminations:

Driving Efficiency & Sustainability.

Utilizing the state-of-the-art material to provide the most suitable electric bus motor core for your high performance needs.

Exceptional quality motor cores minimizing noise and vibration for your electric bus motors.

Tailored designs to meet specific bus motor core requirements and performance goals.