Precision-Engineered Laminations for Peak Motor Performance.

Yucca Manufacturing delivers custom-engineered permanent

magnet motor core laminations, optimizing efficiency, power

density, and torque for your high-performance applications

and more.

Your Trusted Partner for High-Performance Motor Core Solutions

With over half a century of experience in motor core design and lamination technology, Yucca Manufacturing strives to deliver innovative solutions for a wide range of industries.

Our team of consultants is dedicated to providing you with the most suitable material choices for laminations and electrical steel grades, maximizing your motor’s efficiency, performance, and lifespan.

We offer access to stamping progressive die set up, simple die and Wire EDM manufacturing methods for your Permanent Magnet (PM) motor core lamination, tailoring our approach to each customer’s unique needs and specifications.

Utilizing inspection model from Keyence, we rigorously assess lamination products and provide product inspection reports, ensuring exceptional quality and reliability for your motor applications.

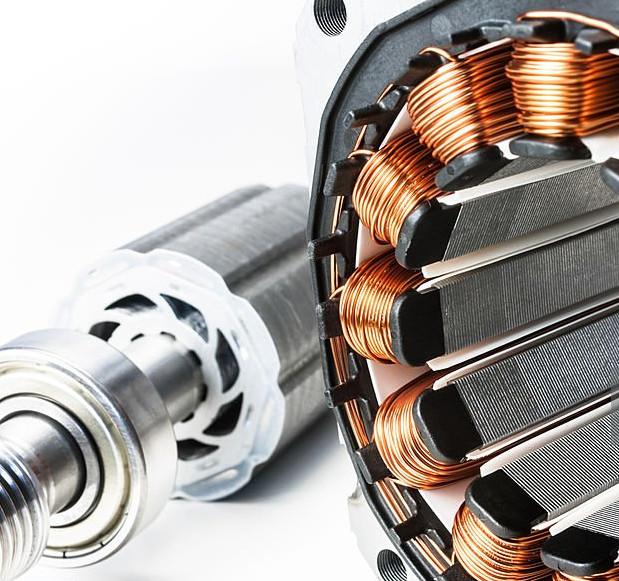

The high magnetic flux density of PM motor cores provides superior performance in a compact and space-saving design.

Permanent magnets in the core reduce electrical losses and energy consumption, significantly improving overall motor efficiency.

PM motor cores deliver consistent and strong torque, particularly at low speeds, enhancing motor performance across applications.

Efficient core design minimizes eddy current and hysteresis losses, resulting in less heat and cooler motor operation.

With fewer moving parts, PM motor cores reduce maintenance needs, offering enhanced reliability and durability.

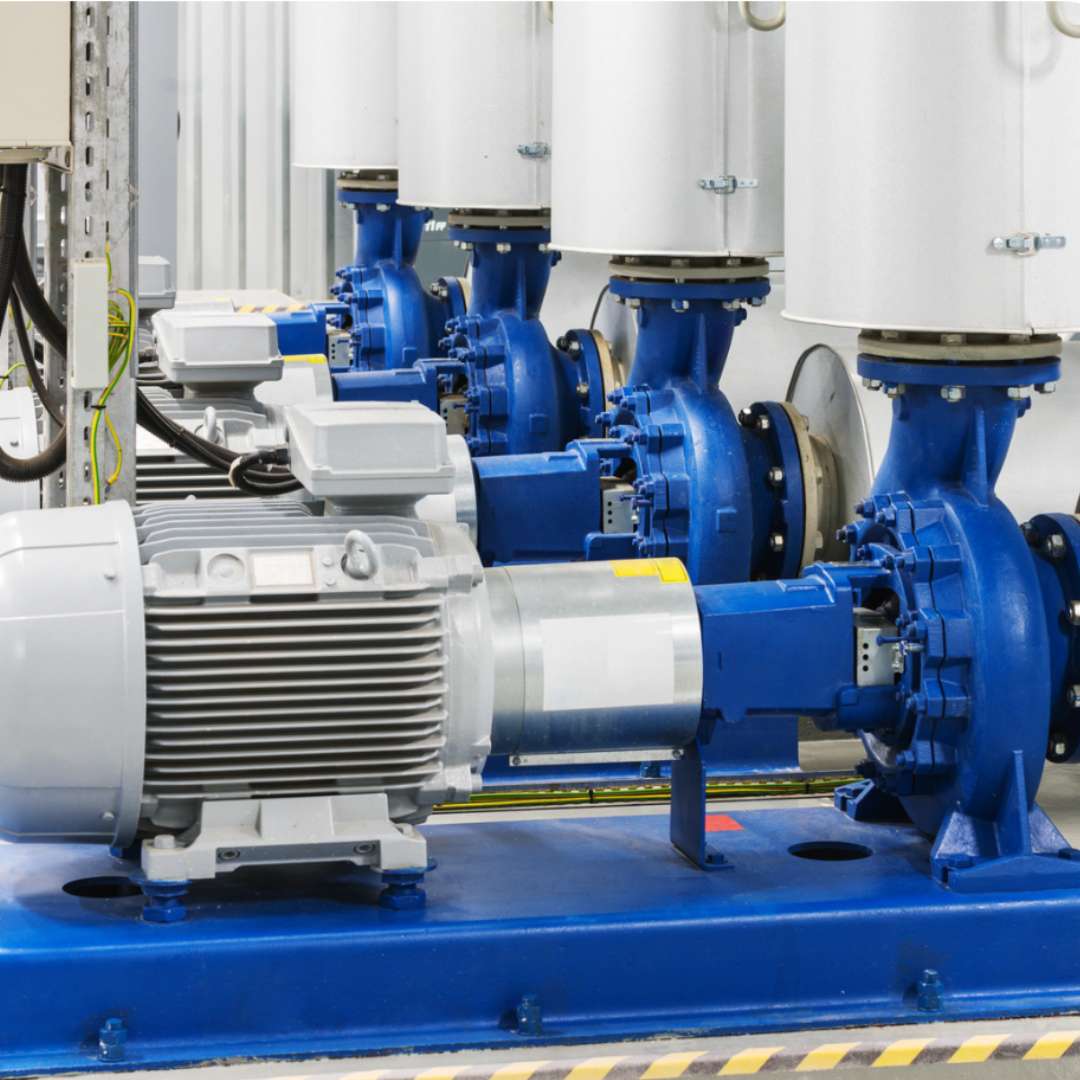

Crucial for high-efficiency and high-power-density motors in electric cars.

Powers machinery and robots, providing precise control and high torque.

Used in generators to efficiently convert mechanical energy from wind into electricity.

Essential for precise and reliable operation in equipment like MRI machines and surgical robots.

Found in efficient, low-noise appliances such as washing machines and HVAC systems.

Employed in aircraft systems where efficiency and weight are critical.

Ideal for applications requiring reliable, high-torque operation.

Converts stored electrical energy into mechanical energy for various applications, including backup and renewable energy systems.