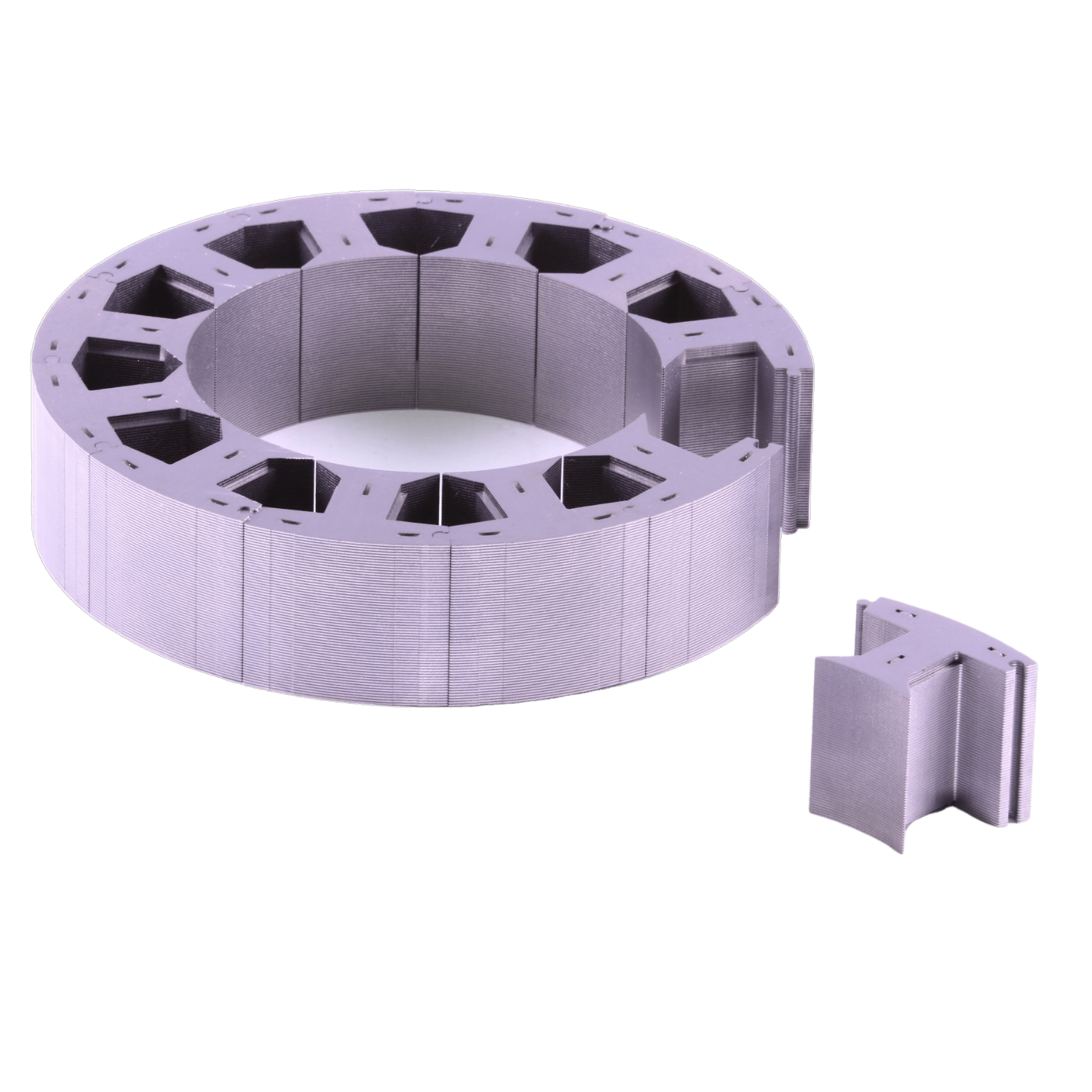

High-Performance Electric Scooter Motor Cores:

Boost Range & Performance.

Our customizable solutions tailor designs to meet specific scooter motor core requirements, optimizing performance for different models.

Choose Yucca for superior scooter motor core technology.

Optimized the lamination quality based on the core design and material for minimal energy losses and maximum efficiency, allowing riders to go farther on a single charge.

Reduced noise and vibration for your motor core applications.

Enhanced thermal management based on your material selection and lamination thickness for consistent performance, even in challenging conditions.

Tailored designs to meet specific scooter motor core requirements, optimizing performance for different models and riding styles.