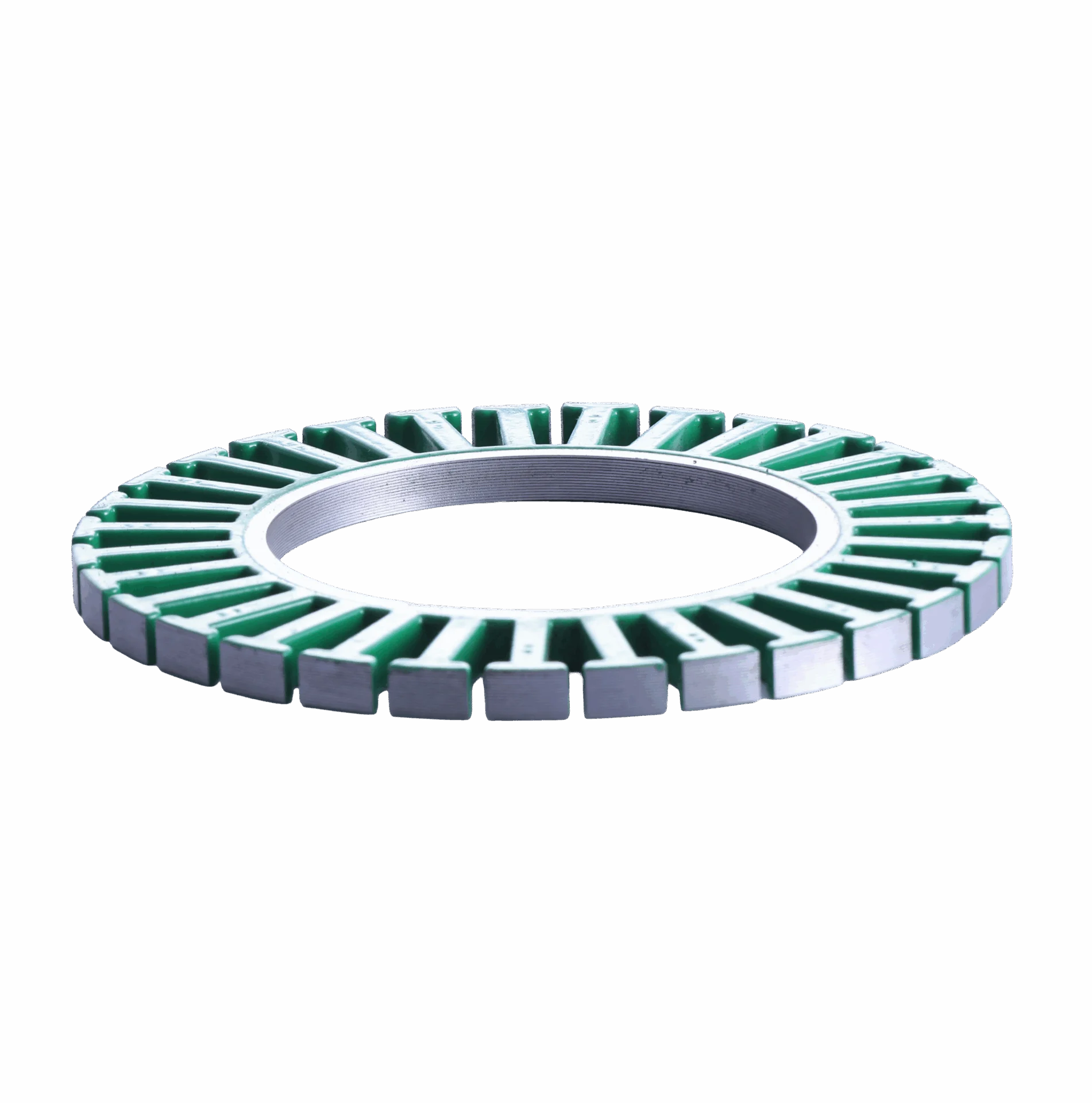

Precision Servo Motor Core Laminations: Unleash High Precision Control and Superior Performance.

Yucca Manufacturing offers custom-engineered servo motor core laminations, optimizing efficiency, torque, and response time for your high-performance applications and more.

Your Trusted Partner for High-Performance Motor Core Solutions

The advanced design of servo motor cores minimizes eddy current and hysteresis losses, resulting in lower thermal output and a prolonged motor lifespan.

Servo motor cores are engineered for quick magnetic field changes, enabling rapid acceleration and deceleration, ideal for dynamic applications.

High-quality servo motor cores enhance motor durability, reducing maintenance frequency, though overall needs depend on other components and operating conditions.

The precision-engineered cores provide exceptional accuracy in positioning, speed, and torque, ensuring superior control in precision applications.

Optimized servo motor cores maximize energy conversion efficiency, reducing losses and improving overall motor performance.

Servo motor cores offer high power density, allowing for a smaller footprint while delivering robust performance, making them ideal for space-constrained applications.

Servo motors are commonly used in industrial automation for precise control and efficient operation in robotics, CNC machines, and conveyor systems.

In robotics, servo motors are essential for controlling the movement of robotic arms, grippers, and actuators, providing the necessary accuracy and reliability.

Servo motors are utilized in aerospace applications such as drone propulsion and flight control systems, where precision and reliability are crucial.

Servo motors are integrated into various automotive systems, including electric power steering and throttle control, to enhance vehicle performance and responsiveness.

Servo motors play a vital role in medical devices like surgical robots and prosthetics, where precise motion control is required.

Servo motors are used in wind turbine systems, particularly in pitch and yaw control, to optimize energy capture.

In consumer electronics, servo motors are found in devices like cameras and printers, providing smooth and accurate operation.