Self-Bonding Electrical Steel : Elevate Motor Core Efficiency and Performance.

Yucca Manufacturing offers premium self-bonding electrical steel for high-performance motor core laminations, delivering superior efficiency, reduced losses, and providing high magnetic flux and more.

With half a century of experience in motor core design and lamination technology, Yucca Manufacturing is dedicated to offering innovative self-bonding electrical steel solutions.

Our consultants are here to assist if you’re unsure about material selection. We’ll help you choose the most suitable electrical steel grade, including self-bonding electrical steel, to ensure optimal performance for your electric motors.

We offer a wide range of non-oriented electrical steel grades tailored to your specific needs, along with access to manufacturing processes such as progressive die stamping, Wire EDM, and simple die.

Our commitment to quality is evident through the utilization of specialized heating equipment to achieve perfect bonding between laminations, and by leveraging a rigorous inspection process using Keyence inspection models.

Partner with Yucca to unlock the full potential of self-bonding technology and experience exceptional efficiency and performance for your electric motors.

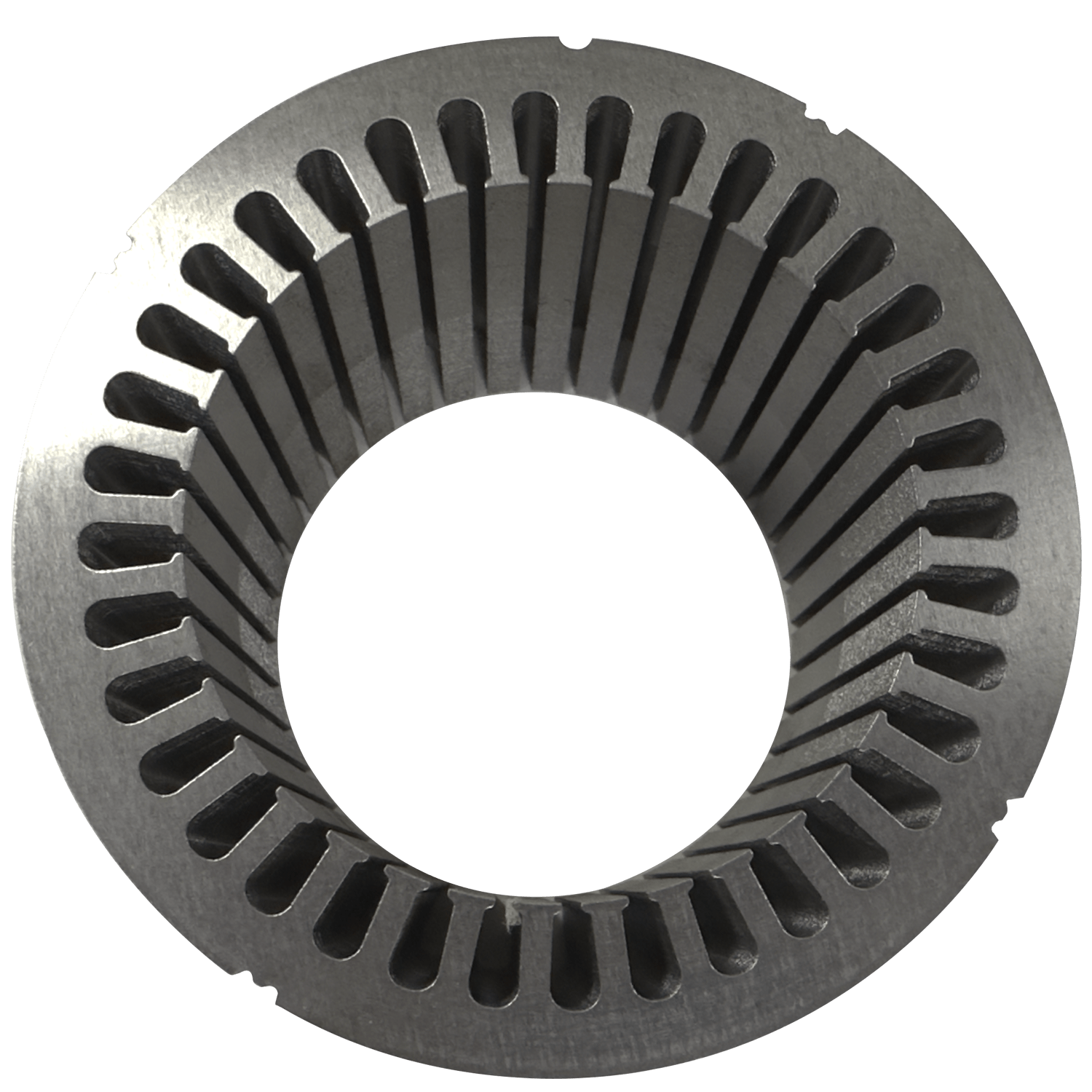

Self-bonding electrical steel provides minimal iron core loss and high magnetic flux density, making it ideal for high-performance electric motors.

Self-bonding technology allows each electrical steel layer to bond together after the heating process, eliminating the need for welding and riveting.

Create a more rigid and robust core structure, reducing noise and vibration.

Higher efficiency and power density for improved range and performance.

Reduced energy consumption and operating costs for pumps, fans, compressors, and other industrial equipment.

Improved efficiency and quieter operation for household appliances.

Lightweight and high-performance motors for drones and electric aircraft.