High-Precision Linear Motor Laminations: Powering

Smooth, Efficient Motion.

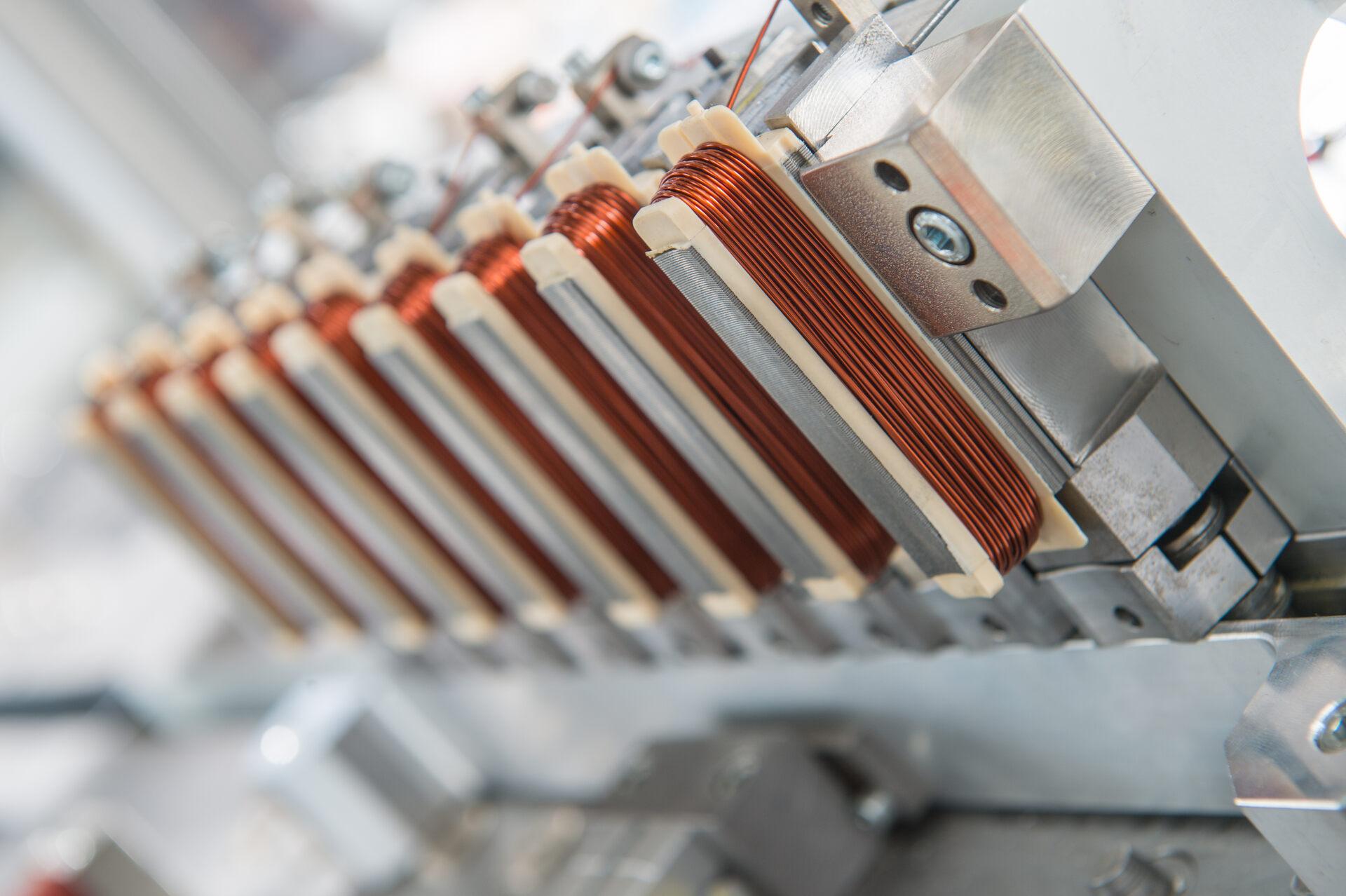

Quality laminations reduce eddy current and hysteresis losses, aiding in higher force density and more efficient power transfer.

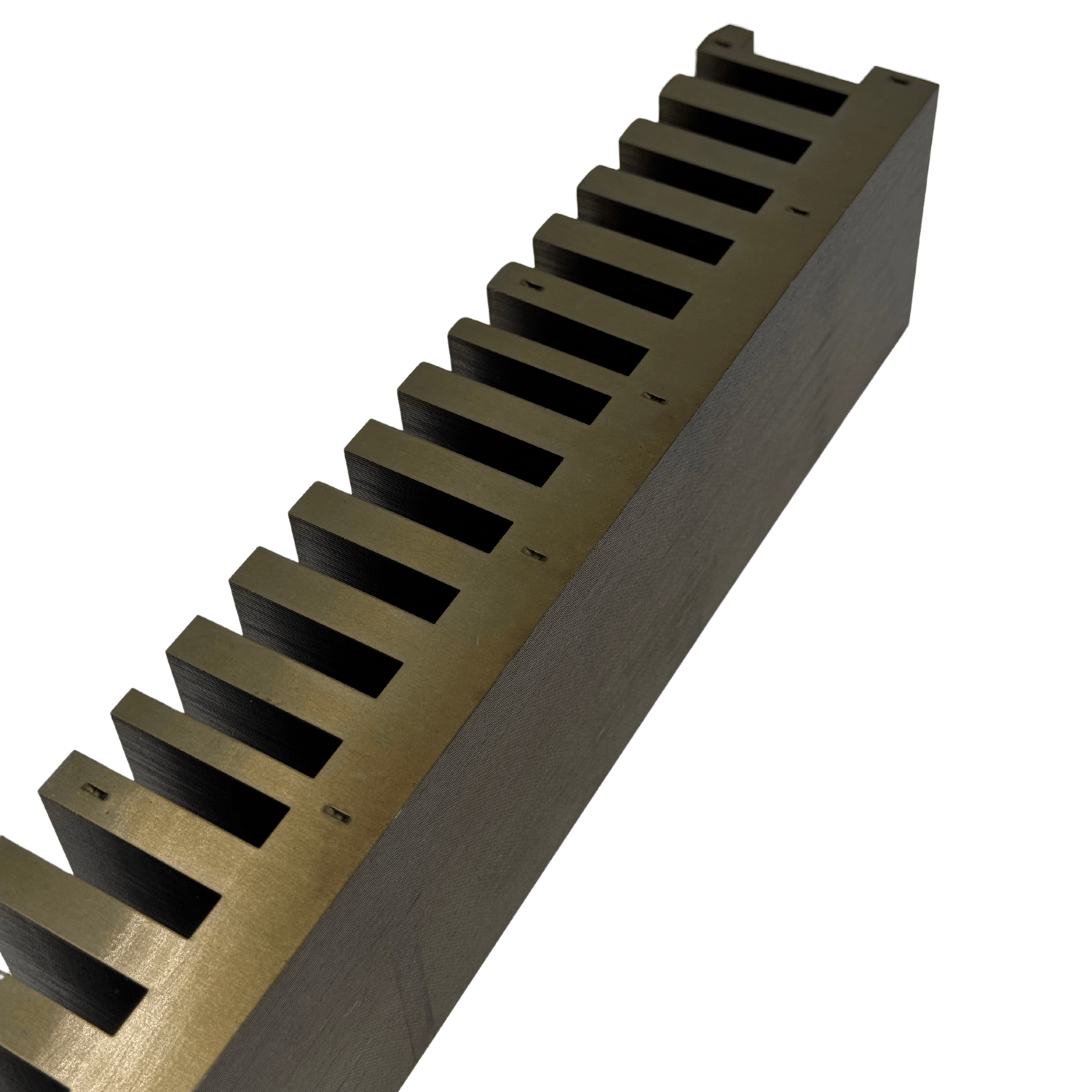

Lamination designs can be customized to suit specific applications, considering stroke length, force needs, and environmental factors.

Lower cogging torque enables smoother, vibration-free motion, enhancing motor performance.

Reduced core losses in laminations contribute to better energy efficiency.

Various electrical steel grades are available, offering a balance between performance and cost.