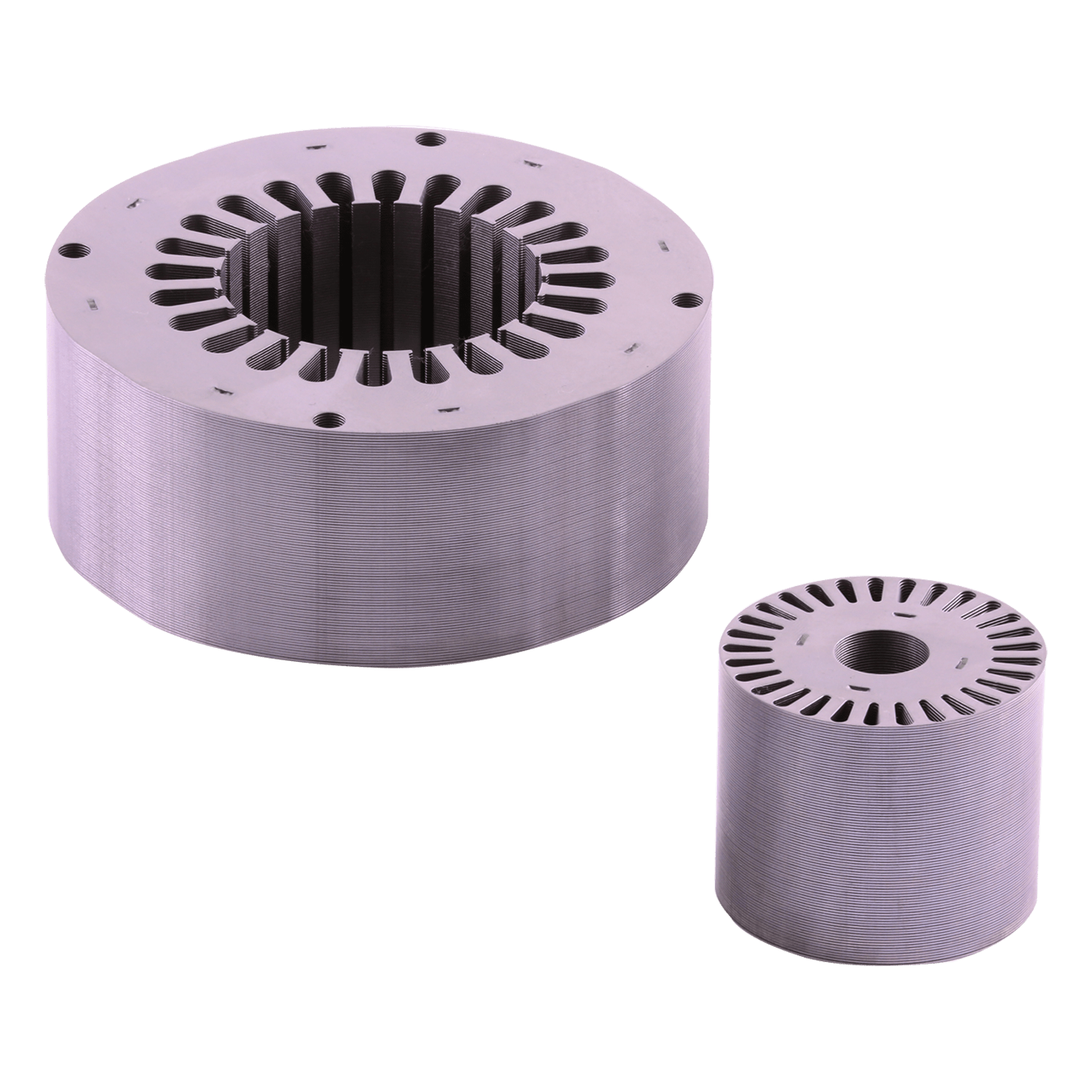

High-Efficiency Induction Motor Core Laminations:

Power Your Applications with Precision.

Your Trusted Partner for Optimized Motor Core Solution

Induction motor cores are designed to reduce energy losses, leading to higher efficiency in converting electrical energy into mechanical energy.

Efficient heat dissipation, aided by proper core design and material selection, helps the motor run cooler, preventing overheating and extending its lifespan.

Designed for stable operation, induction motor cores provide consistent and reliable performance across a wide range of applications.

Suitable for a variety of industries, from manufacturing to HVAC systems.

Designed to improve the efficiency of ventilation, air conditioning, and heating systems, motor core laminations can help reduce energy consumption.

These laminations enhance the operational efficiency and reliability of pumps used in sectors like water supply and chemical processing.

Supporting the efficiency of compressors, motor core laminations play a key role in industrial refrigeration and air compression applications.

In some EVs, induction motor laminations boost efficiency and performance, though Permanent Magnet motors are more common.

In manufacturing, motor core laminations contribute to the enhanced performance and longevity of essential equipment like lathes, milling machines, and drills.

Smooth and efficient operation in elevators and escalators is supported by high-quality motor core laminations.

In building automation, especially HVAC, induction motor laminations enhance efficiency, though other systems may use different motors.

In commercial material handling equipment, motor core laminations contribute to precise and reliable operations, including in conveyor systems.

Efficiency and quiet operation in ceiling fans are achieved through well-designed motor core laminations.

Residential air conditioning units benefit from high-efficiency laminations that contribute to effective cooling and energy conservation.

Reliable and smooth functionality in garage door openers is supported by robust motor core laminations.