*note: In Permanent Magnet Motor Scenario

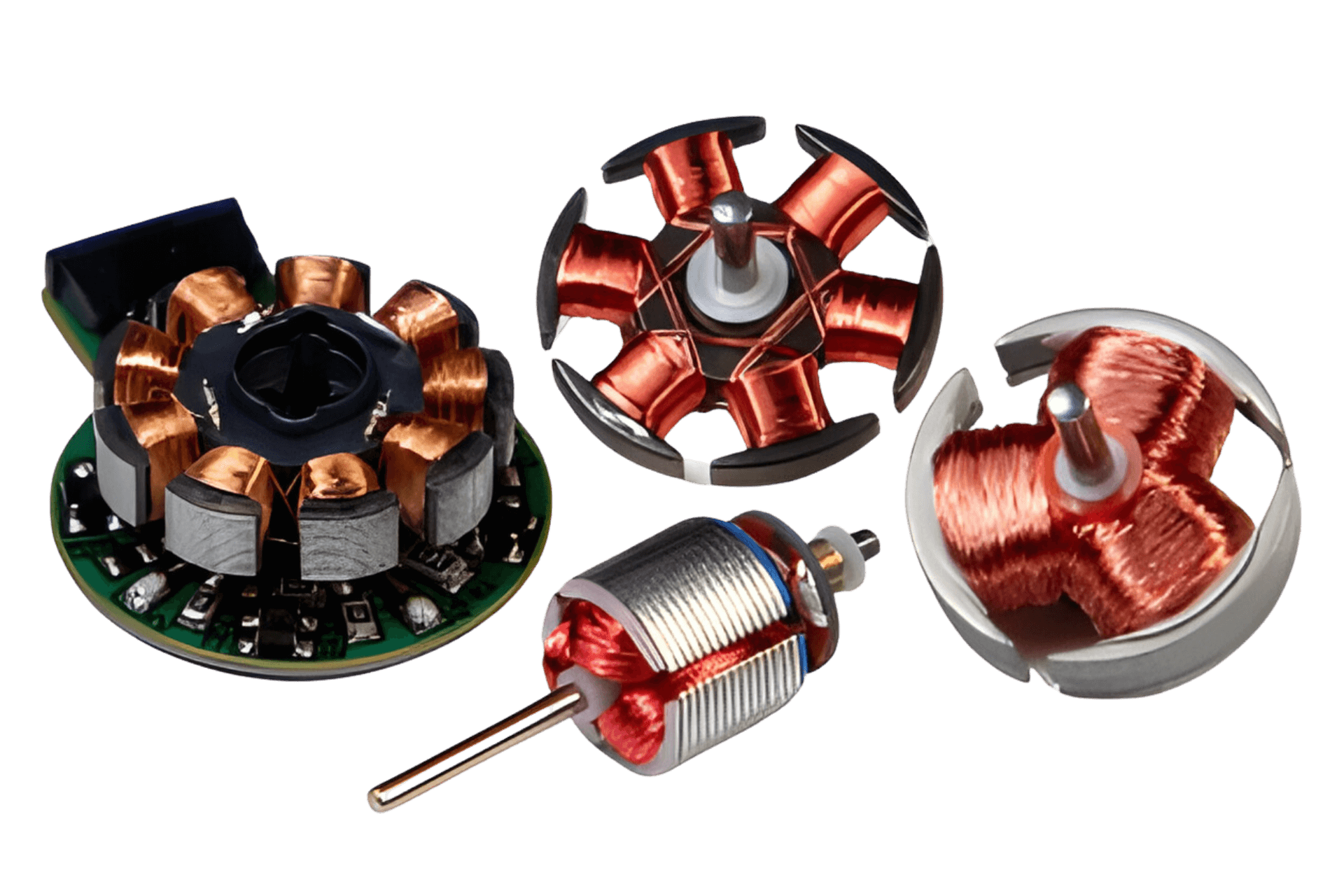

*note: In Drone Motors

Yucca is Both a Consultant and a Supplier Serving Motor Core Inquiries.

Regardless of production size, our rigorous inspection process ensures compliance with the IATF 16949:2016 Supplier Quality Management Standard held by our stable partner.

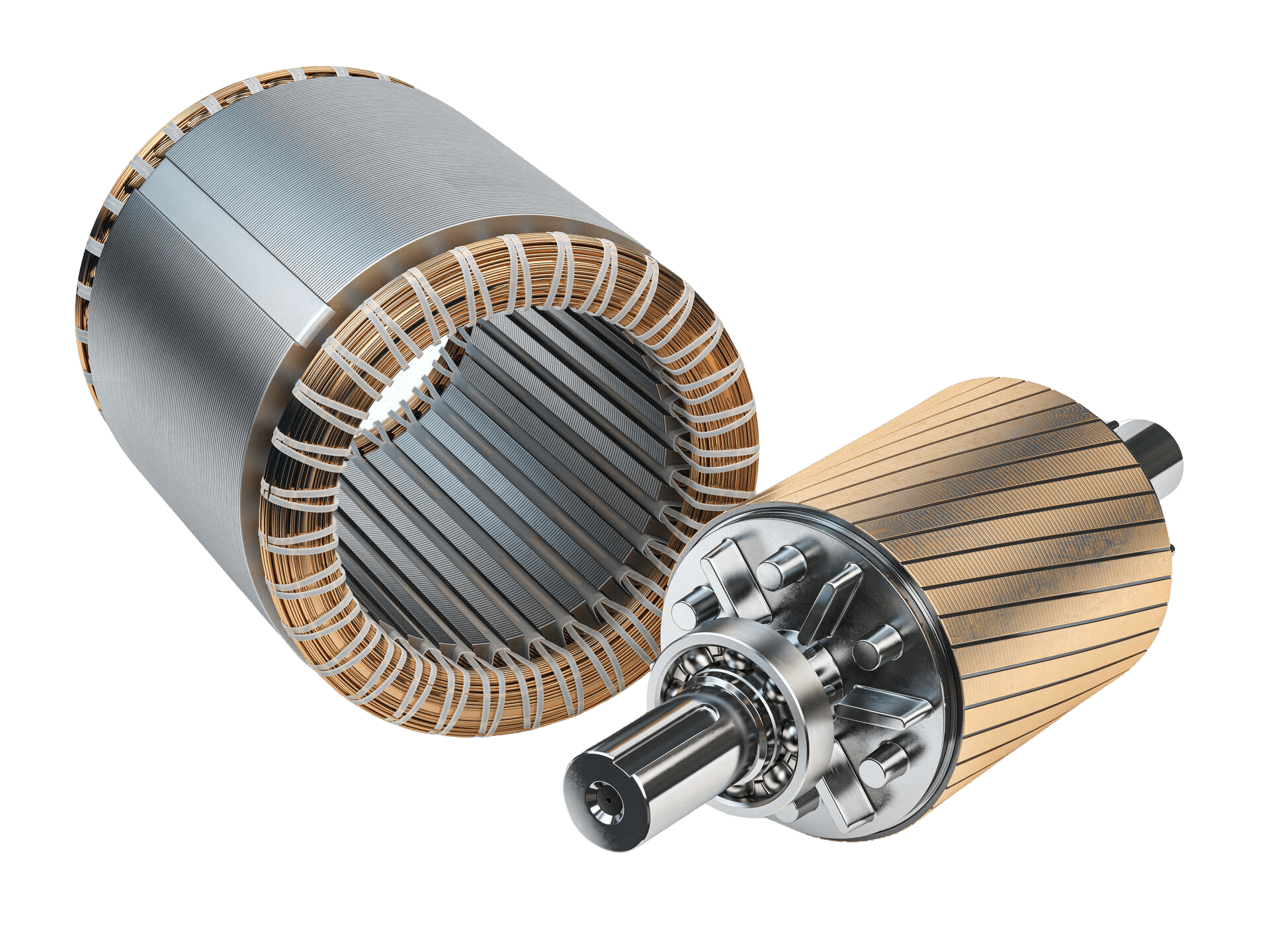

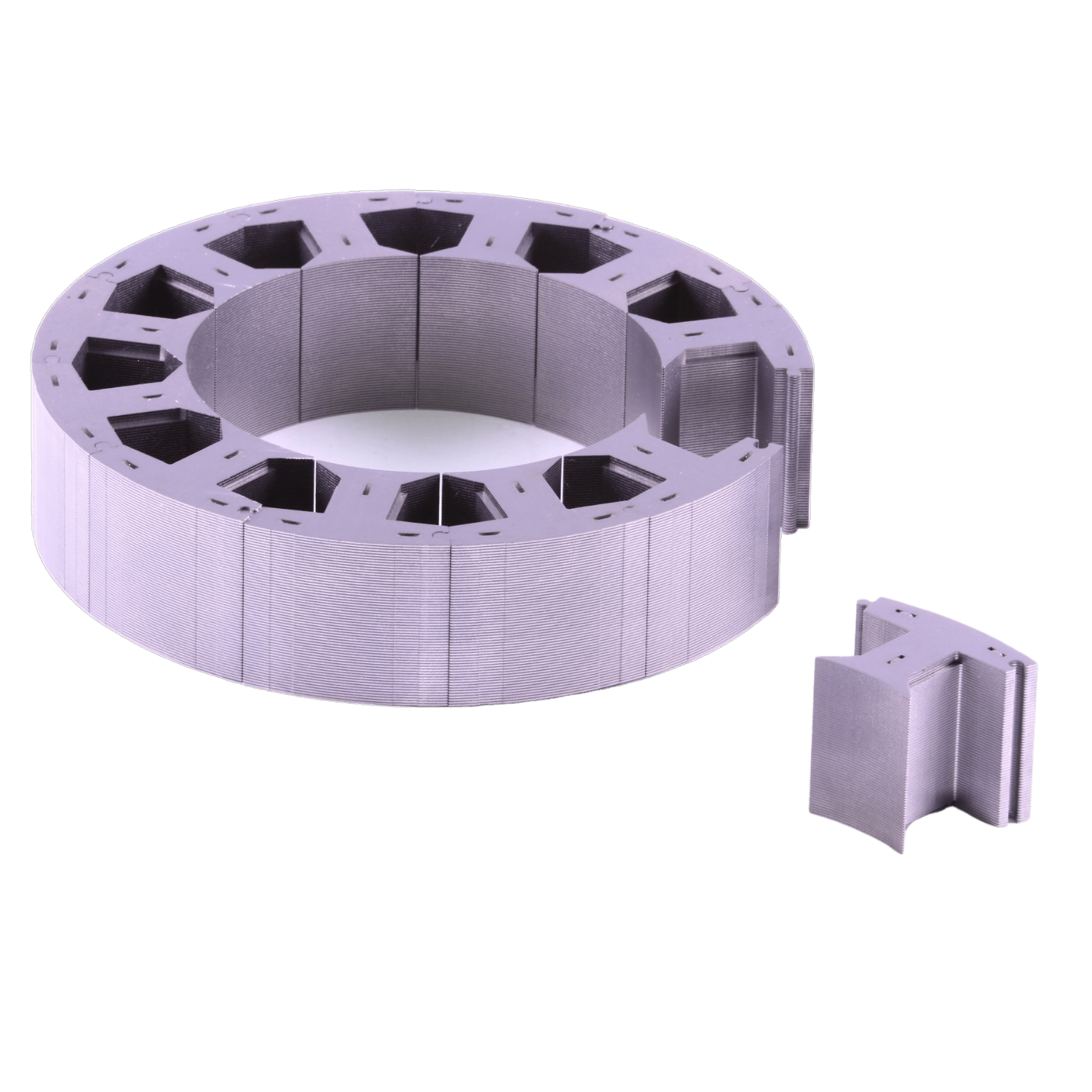

We have extensive experience in delivering the latest self-bonding electrical steel motor cores, which are ideal for high-efficiency applications due to their low iron loss and high magnetic flux, optimizing exceptional performance and reliability.

Our IATF 16949 certified manufacturing partners ensure high-quality products, meeting rigorous automotive industry standards, and guarantee that product undergoes stringent inspection and quality control.

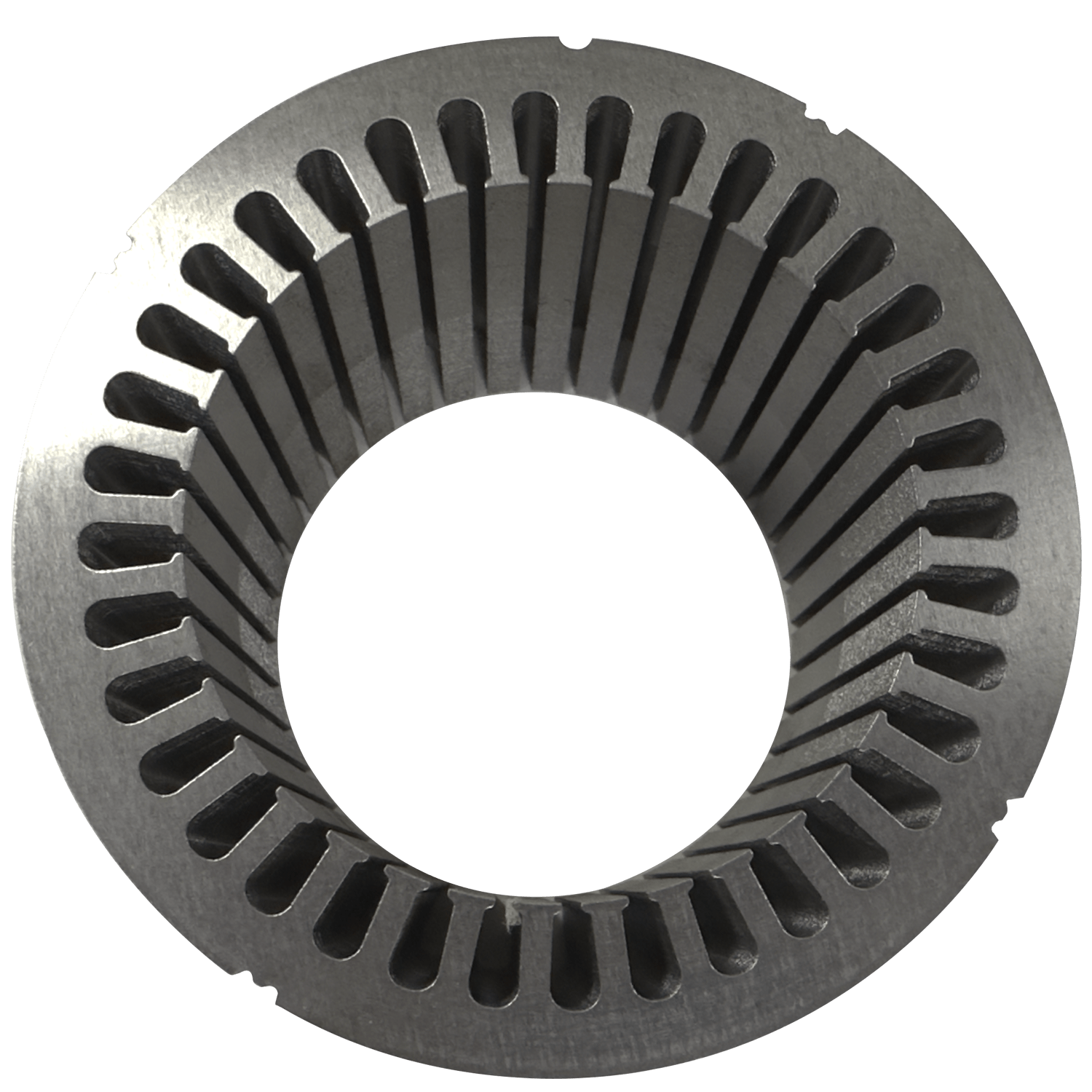

Products are laminated by Japanese Punch Presses and inspected by Keyence’s inspection model, ensuring the finest quality.

Fast Production speed to fulfill rush orders.

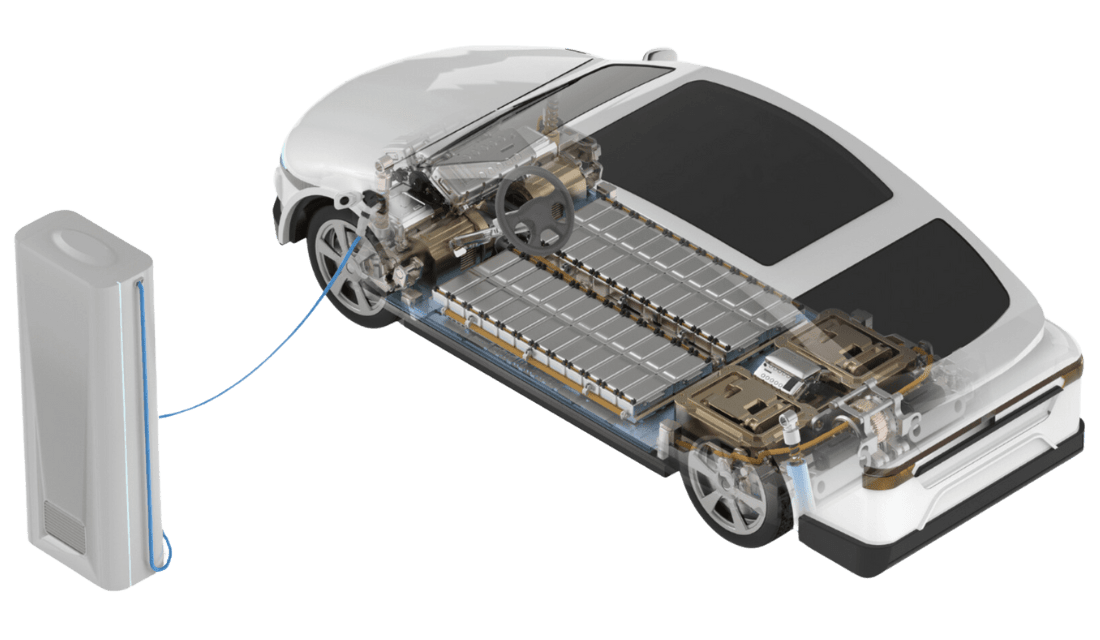

We’re experienced in delivering specialized EV and Drone’s motor core solutions to fit your specific needs and requirements.

Our professional R&D team has half a century of experience, continually innovating and enhancing product performance. They adopt the latest technologies and methods to ensure the products meet the highest standards.

We have extensive experience in delivering the latest self-bonding electrical steel motor cores, which are ideal for high-efficiency applications due to their low iron loss and high magnetic flux, ensuring exceptional performance and reliability.

We respond swiftly to customer needs, providing quick quotations. Regardless of the project size, we deliver accurate quotes in the shortest time, allowing you to swiftly move into the development phase.

There's no need to worry about minimum order quantities; we support flexible ordering needs of all sizes. We are dedicated to delivering high-quality prototypes, ensuring your project can start smoothly and iterate quickly.

We offer services in English, Japanese, and Chinese, among others, to ensure seamless communication. Our team provides professional support in multiple languages, ensuring you can easily understand and participate in every development stage.

Our IATF 16949 certified manufacturing partners ensure high-quality, defect-free products, meeting rigorous automotive industry standards, and guarantee that every product undergoes stringent inspection and quality control.

ucca Manufacturing utilizes a sophisticated tracking system to monitor every motor core throughout its production journey, incorporating a QR code system for comprehensive accuracy and quality control.

Utilizing an industry-leading Keyence inspection model with a precision of 12μm, we verify the dimensional accuracy of motor cores and provide product reports, ensuring the highest quality and consistent performance.

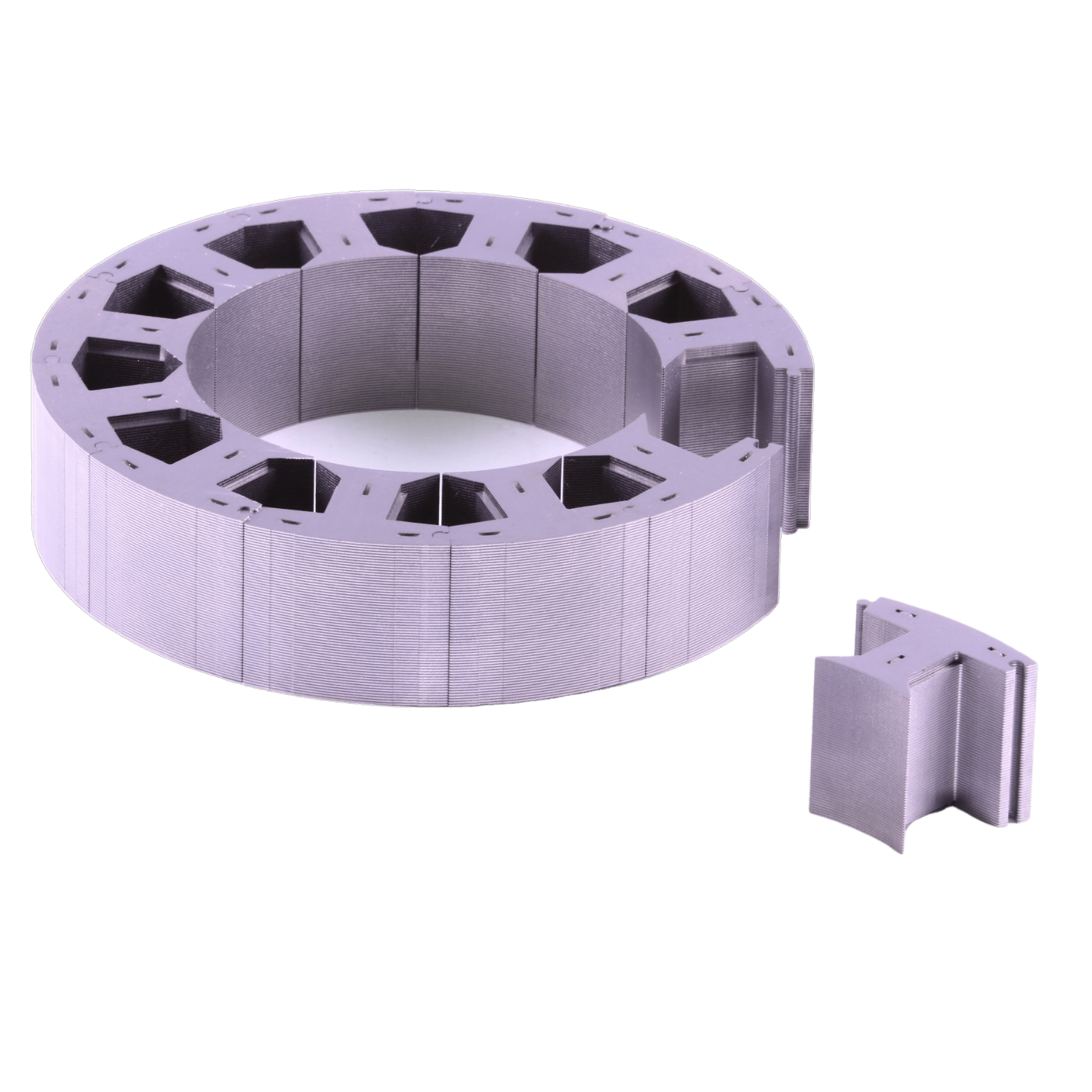

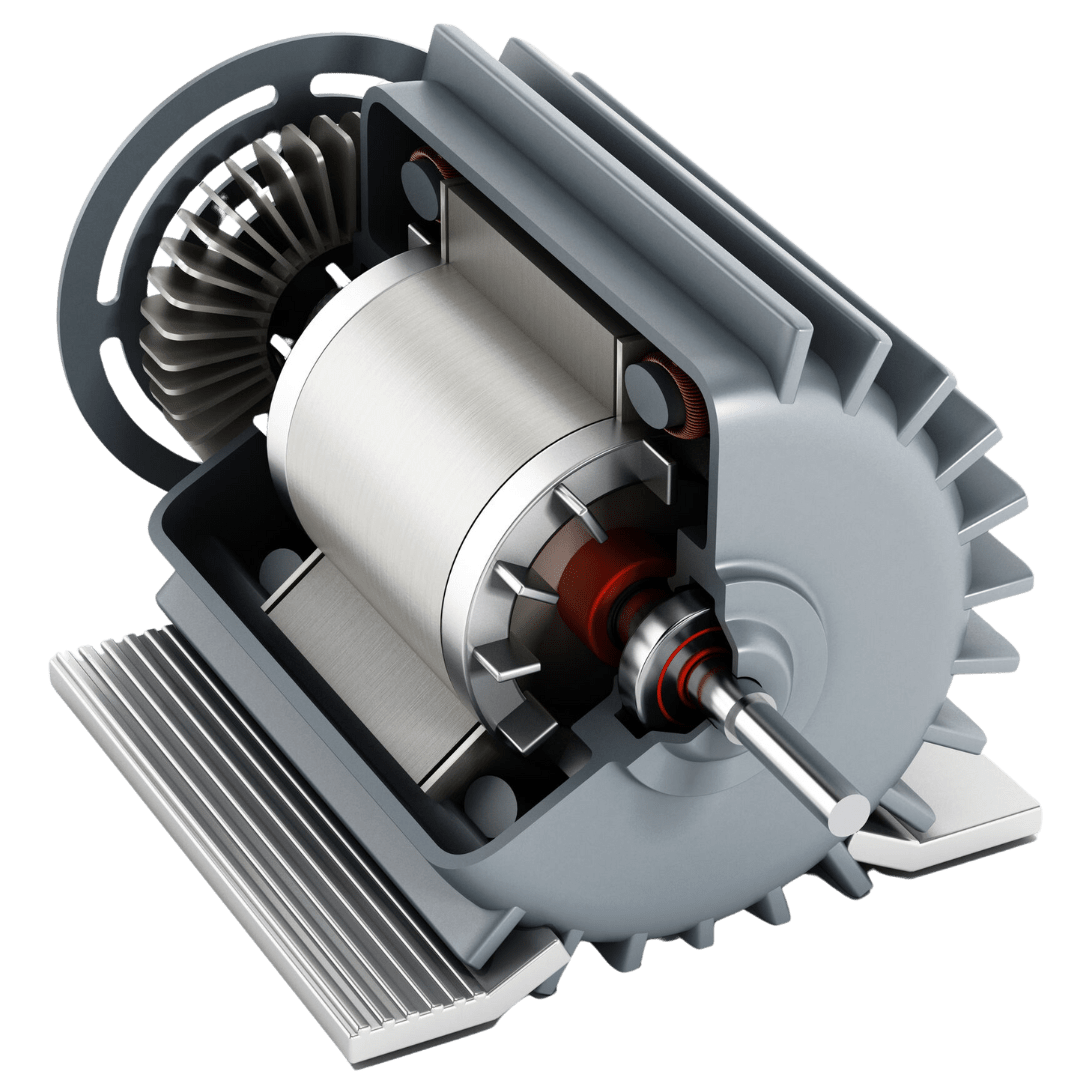

We specialize in providing a wide range of motor core products, from the smallest 10mm to the largest 800mm or above, tailored to various industries. Our solutions are ideal for applications in electric vehicles, drones, CNC machinery, robotics, medical equipment, aerospace, and different types of machine tools using servo motors, showcasing our versatility and expertise and more.

Product | Advantages |

|---|---|

High Efficiency Electric Motor Core | Optimized for energy savings, reduced operating costs |

Self-Bonding Electrical Steel | Reduces eddy currents, simplifies assembly, enhances performance |

Servo Motor Core | Precise control,high torque, suitable for dynamic applications |

Permanent Magnet Motor Core

Lamination | High efficiency,high power density,compact size |

Transformer Core | High efficiency,low core loss |

DC Motor Core Lamination | Simple construction,reliable,cost-effective |

Electrical Steel Lamination / Thickness (mm) | 0.15 | 0.20 | 0.25 | 0.35 | 0.50 |

|---|---|---|---|---|---|

Iron Loss (W15/50) W/kg | 2.06-2.15 | 2.1-2.4 | 2.2-2.5 | 2.04-2.89 | 2.28-5.99 |

Magentic Flux (B50 ) Tesla | 1.63 | 1.65-1.67 | 1.65-1.68 | 1.67-1.71 | 1.68-1.74 |

At Yucca Manufacturing Enterprise Ltd., we employ a rigorous inspection process for our Electrical Steel Laminations, utilizing the renowned Keyence inspection model.

This advanced system ensures that laminations meet the required standards of precision and quality.

By leveraging Keyence’s technology, we can detect even the finest precision with tolerances as small as 1.2μm.

Additionally, we provide comprehensive product reports after inspection, offering our customers detailed insights and assurance of the quality of our motor core solutions.