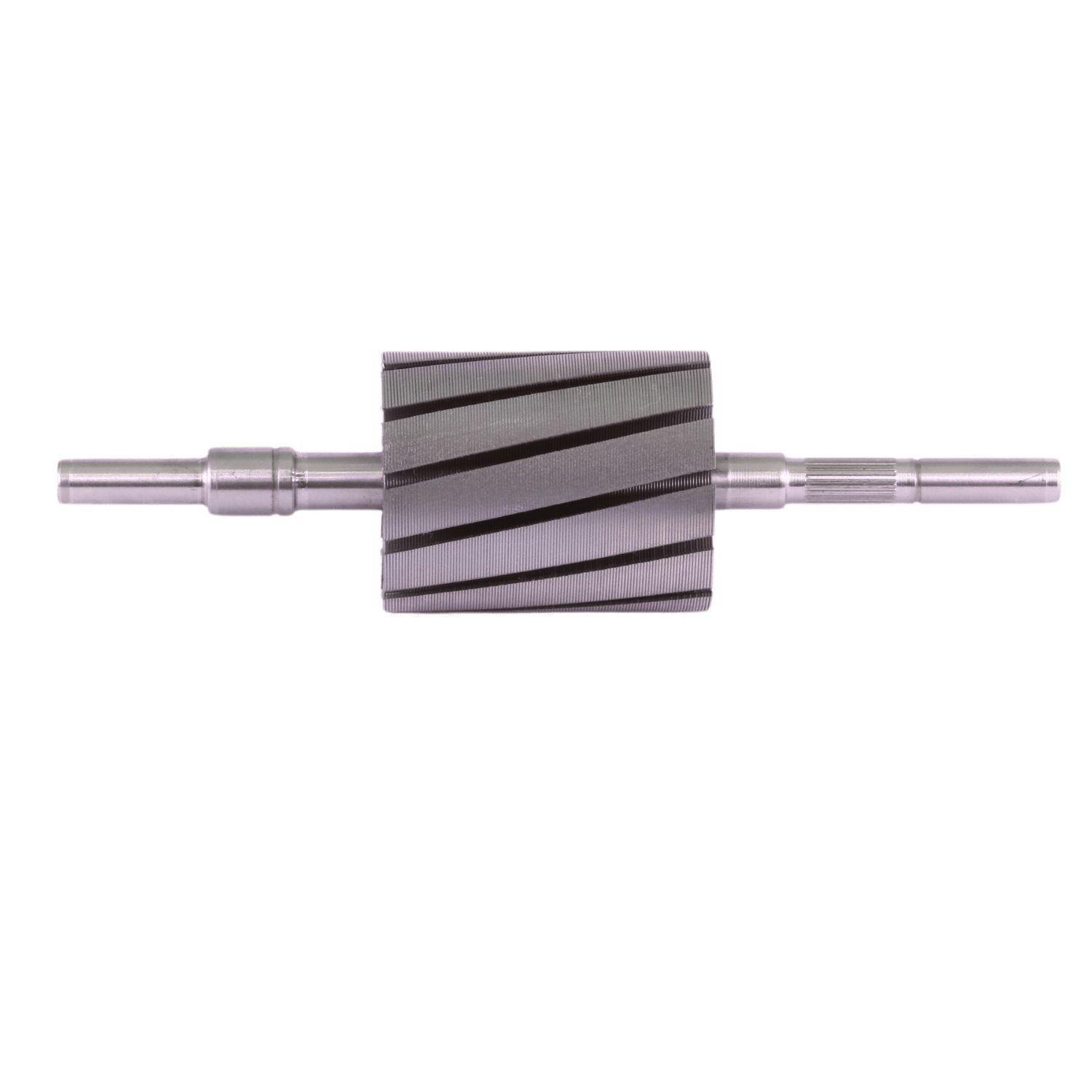

High-Performance DC Motor Core Laminations: Torque and Efficiency.

Your Trusted Partner for DC Motor Core Excellence

DC motor cores offer numerous advantages for DC motors, making them highly reliable and efficient for various applications. Their optimized design ensures high efficiency by converting electrical energy into mechanical energy with minimal losses. Superior torque performance at low speeds makes them ideal for precise control.

These benefits make DC motor cores a preferred choice for high-performance, efficient solutions in diverse applications.

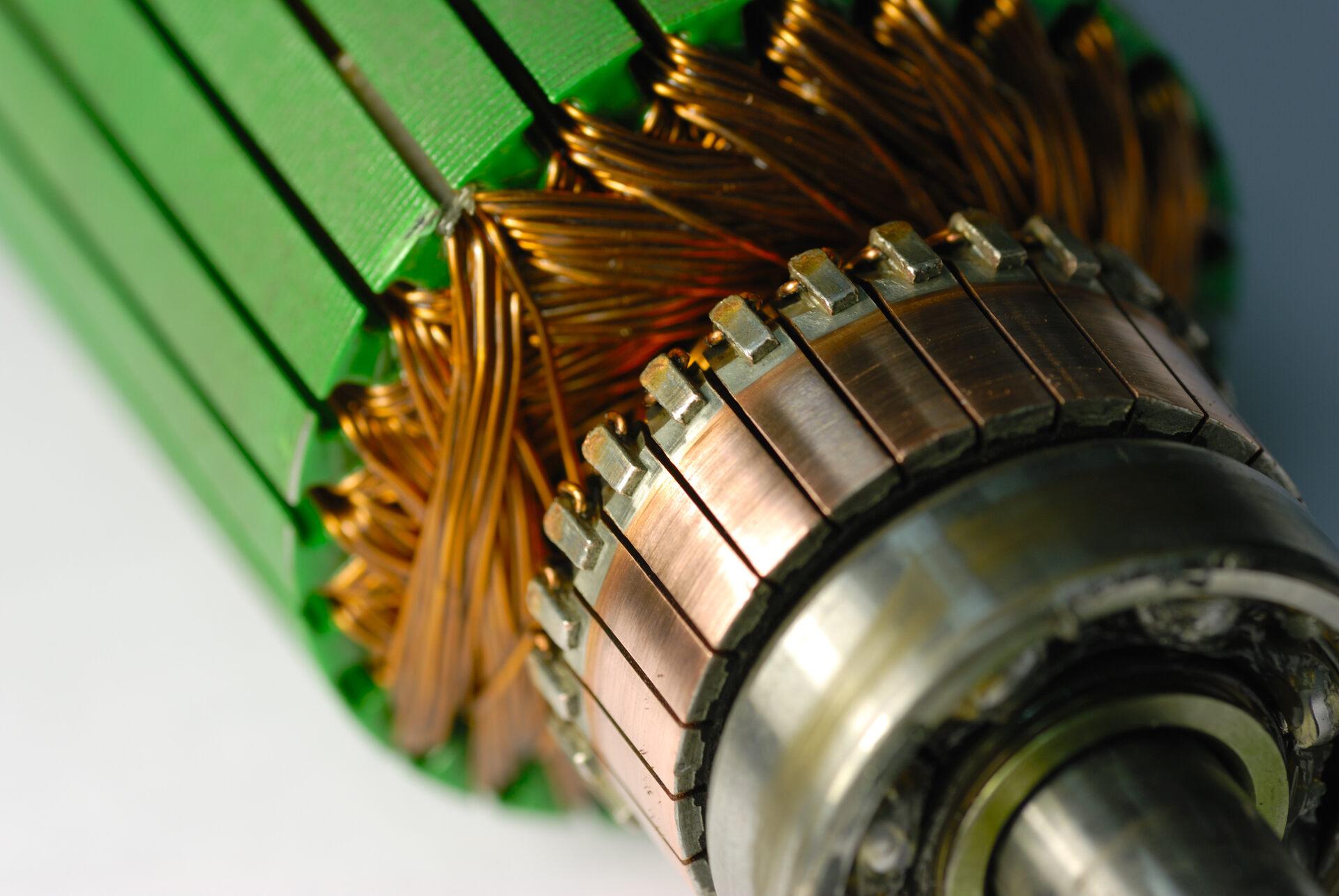

High-efficiency DC motor cores are optimized to minimize energy losses during the conversion of electrical energy to mechanical energy, enhancing overall motor efficiency.

The design and material of the DC motor core provide superior torque characteristics at low speeds, crucial for applications that require precise control.

Advanced DC motor core designs allow for higher power density, enabling the motor to be smaller and lighter while still delivering robust performance.

Durable DC motor cores are engineered for long life, contributing to consistent and reliable motor performance across various operating conditions.

DC motor cores can be customized to meet specific application requirements, ensuring the motor performs optimally for specialized tasks.

The design and material properties of DC motor cores are crucial for effective heat dissipation, preventing overheating and ensuring the motor operates at peak performance.

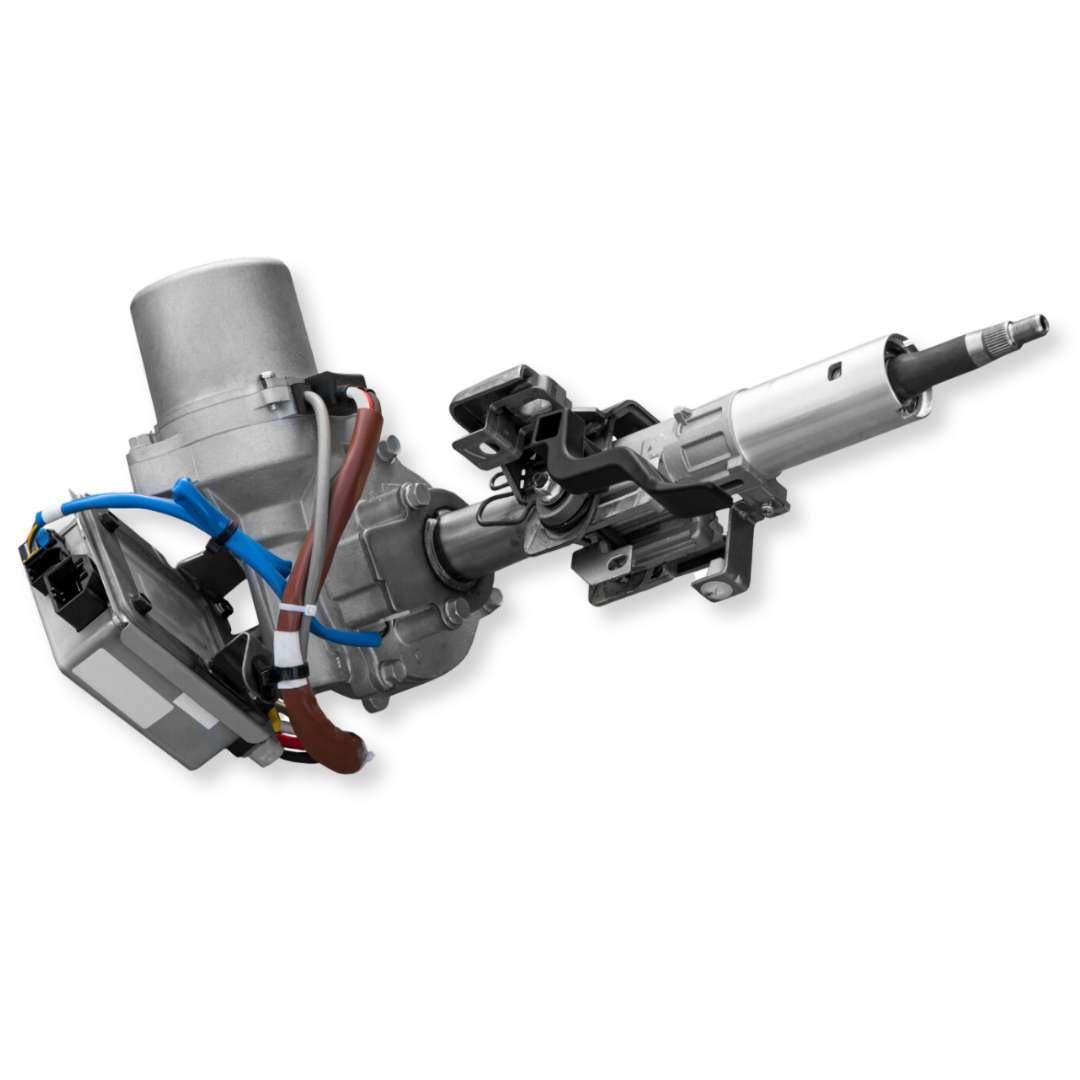

Electric power steering, HVAC systems, window motors, etc.

Robotics, conveyor systems, fans, etc.

Household appliances, power tools, etc.

Drones, UAVs, electric aircraft, etc.

Medical devices, robotics, etc.