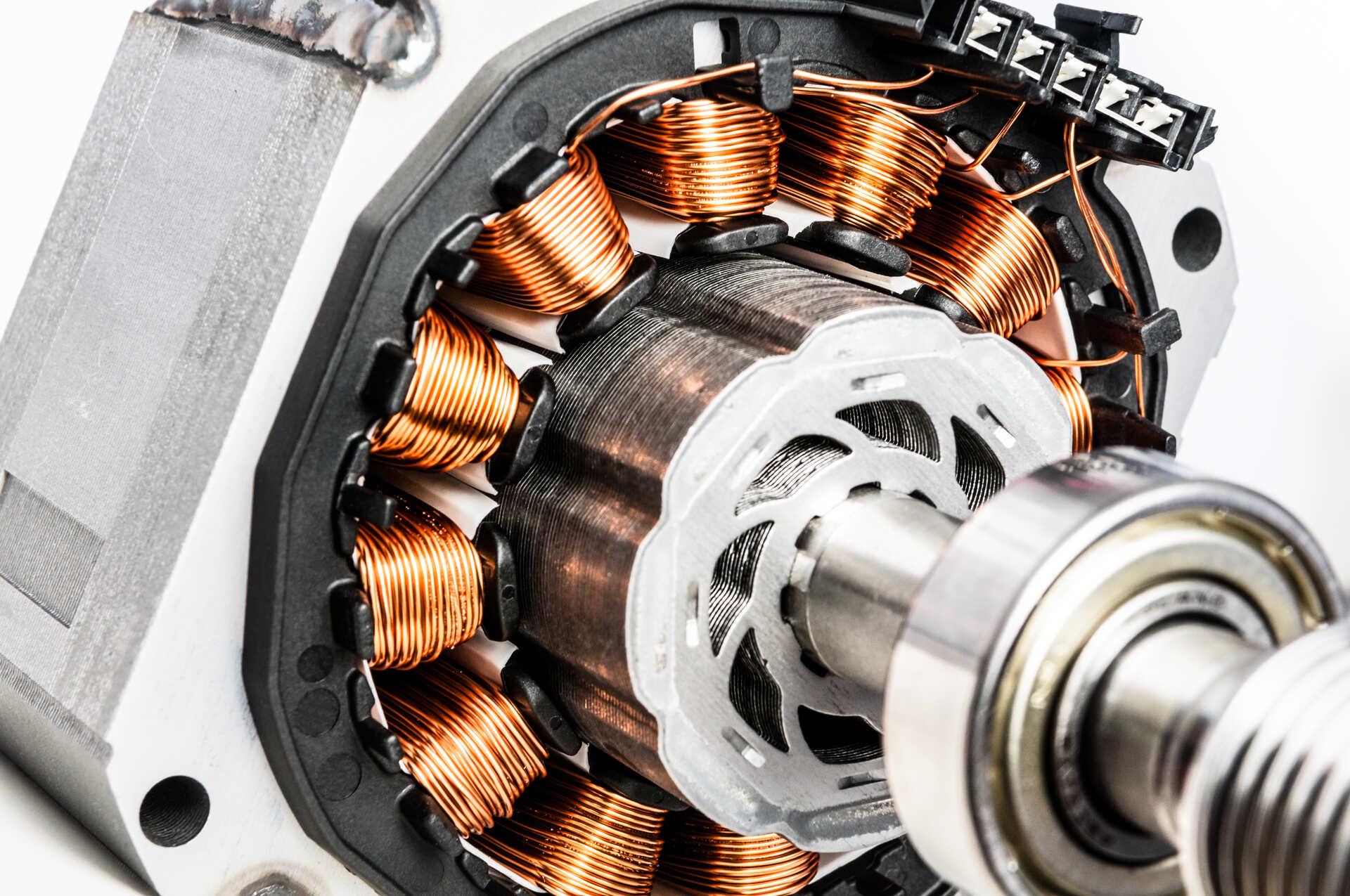

The stationary part of the motor, usually made of laminated electrical steel, which houses the windings (coils of wire).

The rotating part that contains permanent magnets.

The device that manages the power supply to the windings, controlling the speed and direction of the motor.

In a brushed motor, commutation (the process of switching the current direction in the windings) is performed mechanically by brushes and a commutator. In a BLDC motor, commutation is done electronically using an electronic controller.

The controller energizes the windings in the stator in a specific sequence, creating a rotating magnetic field. The rotor, which contains permanent magnets, follows this rotating magnetic field, causing the rotor to turn.

Many BLDC motors use Hall effect sensors or encoders to detect the position of the rotor. This feedback is used by the controller to precisely time the commutation sequence, ensuring smooth and efficient operation.

In terms of performance, BLDC motors can operate at higher speeds, making them suitable for demanding applications. Their compactness is another advantage; for the same power output, BLDC motors are generally smaller and lighter than their brushed counterparts. This makes them ideal for applications where space and weight are critical factors.

BLDC motors are more efficient than brushed motors because there are no friction losses from brushes.

BLDC motors can operate at higher speeds.

The absence of brushes reduces wear and tear, leading to a longer lifespan and lower maintenance.

BLDC motors are typically smaller and lighter for the same power output, though specific designs may vary.

They operate more quietly since there is no brush friction.

BLDC motors offer precise control over speed and position, making them ideal for applications requiring high accuracy.