1. Introduction

1.1 Importance of Servo Motors in Humanoid Robotics

a. Foundation of Motion and Precision

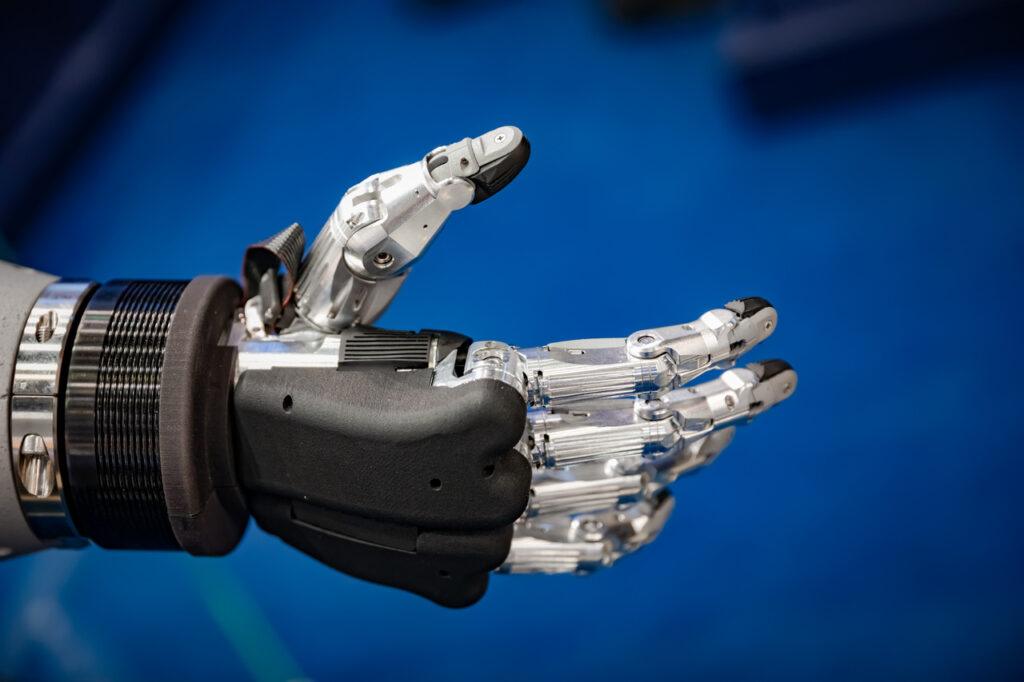

Servo motors are the cornerstone of modern robotics, particularly in humanoid designs. Acting as the “muscles” of these robots, servo motors convert electrical signals into precise mechanical motion, providing exceptional control over position, speed, and torque. This precision is crucial for emulating human-like movements in robotic joints, from subtle gestures to complex, multi-axis tasks. By ensuring smooth and repeatable motion, servo motors make it possible for humanoid robots to interact seamlessly with their environments and perform tasks that require delicate accuracy.

b. Evolving Demands in Humanoid Robotics

The applications for humanoid robots continue to grow, ranging from personal assistance and healthcare to industrial automation. These varied roles demand servo motor solutions that are compact yet powerful, efficient yet adaptable. In healthcare, servo motors empower robots to assist with patient mobility or deliver precision in surgery. In manufacturing, they enable robots to perform repetitive tasks with unwavering consistency. As these demands evolve, so too must servo motor technology, driving innovations in miniaturization, energy efficiency, and AI-enhanced adaptability. Servo motors are not just components—they are enablers of the next generation of humanoid robotics.

This introduction sets the stage for a deeper exploration into how servo motor advancements have shaped, and continue to shape, the field of humanoid robotics.

2. Historical Development of Servo Motors in Robotics

2.1 Early Applications

a. From Industrial Automation to Robotics

Servo motors have been pivotal in the evolution of industrial automation, offering precise control over machinery movements. Their ability to accurately manage position, speed, and torque made them indispensable in manufacturing processes, leading to enhanced efficiency and product quality. This precision laid the groundwork for their integration into robotics, where replicating human-like movements necessitated such exactitude.

b. Growth in Humanoid Robotics

The transition from industrial automation to robotics marked a significant advancement in servo motor applications. As the demand for humanoid robots increased, the need for complex, multi-axis control systems became evident. Servo motors provided the necessary functionality to emulate human movements, enabling robots to perform tasks with greater dexterity and adaptability.

2.2 Key Milestones in Servo Motor Technology

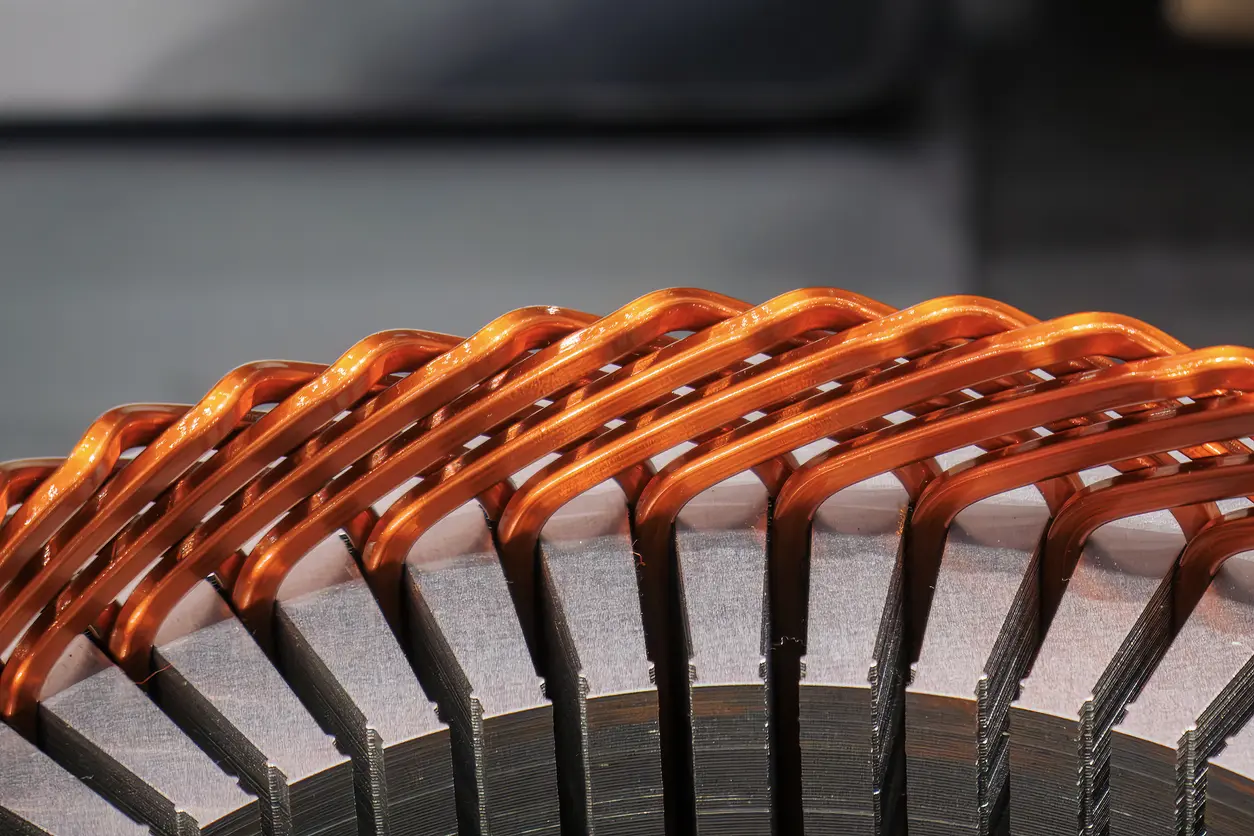

a. Feedback and Control Systems

The integration of feedback mechanisms, such as encoders and sensors, revolutionized servo motor performance. These components allowed for real-time monitoring and adjustments, significantly enhancing motion accuracy. This advancement enabled servo motors to execute intricate tasks with a high degree of precision, which is essential in both industrial and robotic applications.

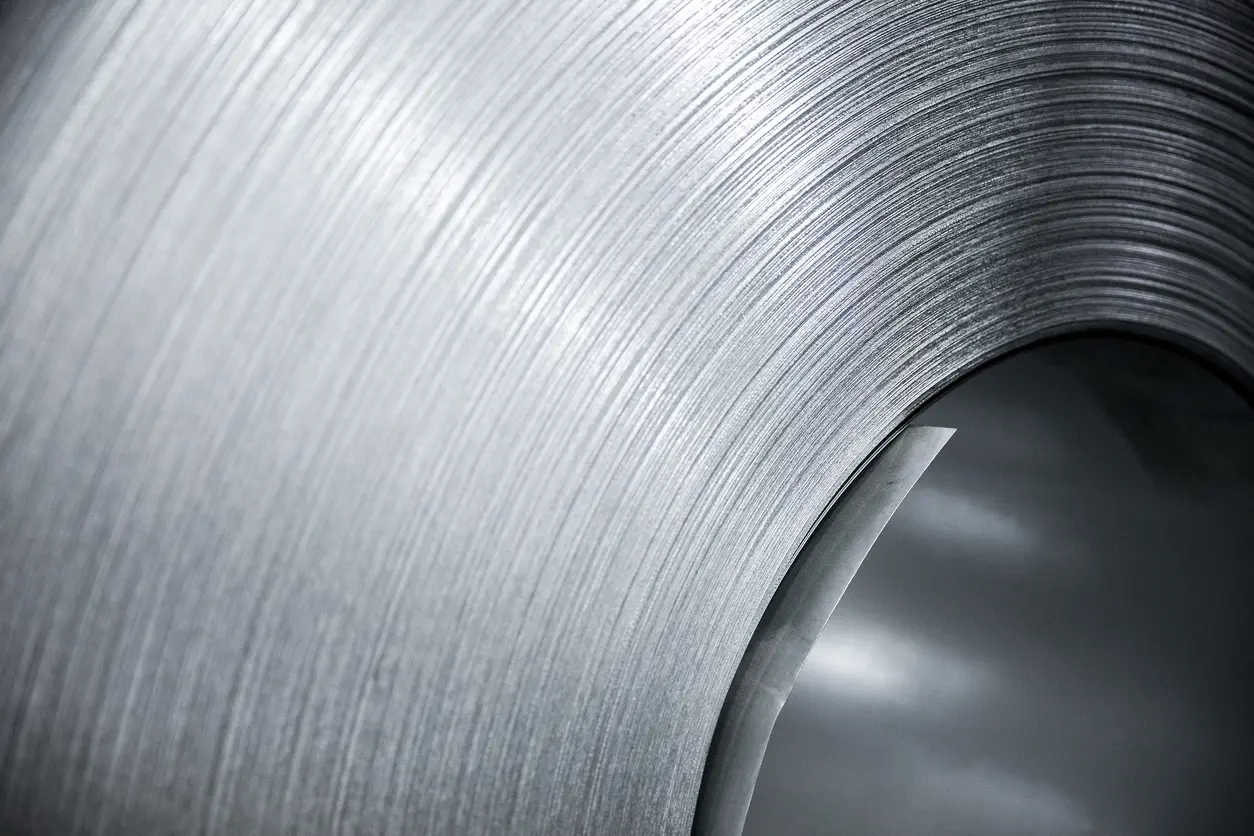

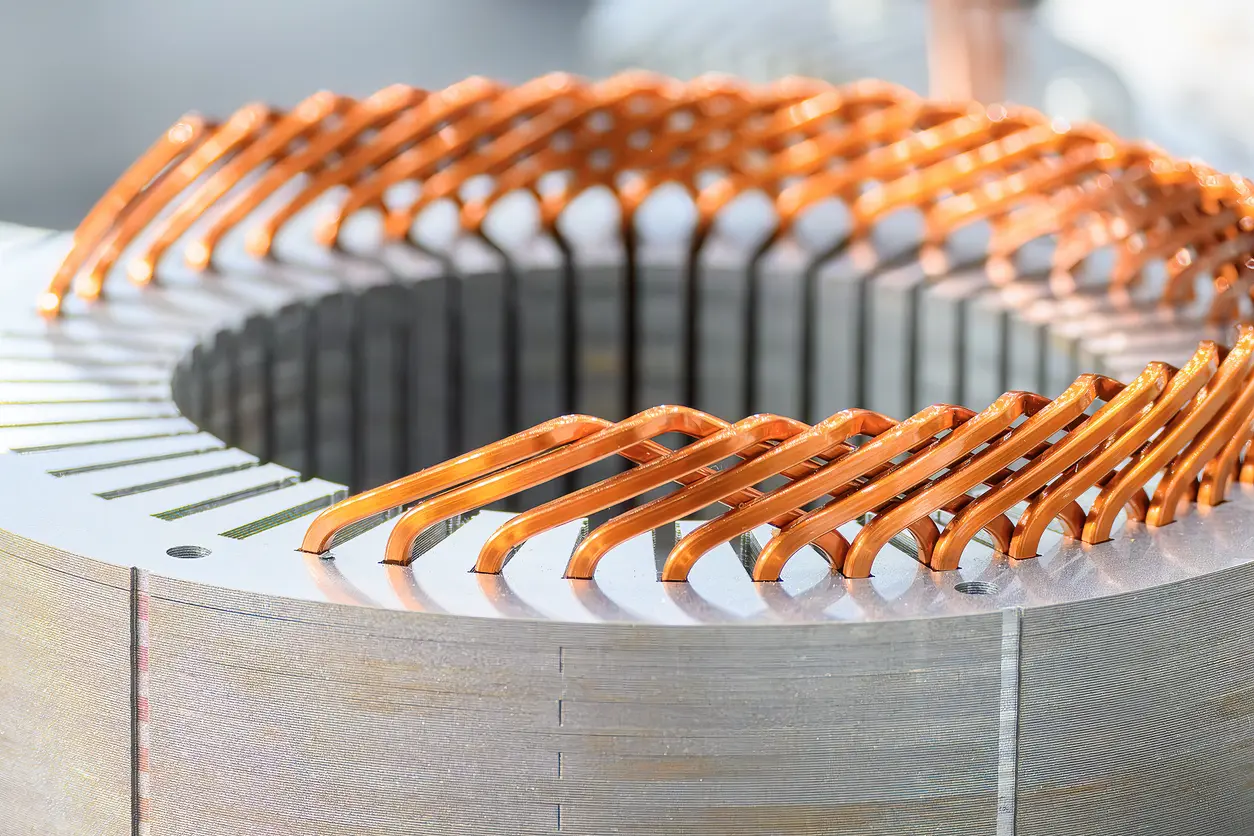

b. Miniaturization and Efficiency

Advancements in materials science and engineering have led to the development of smaller, more efficient servo motors. This miniaturization is particularly beneficial in robotics, where space constraints are common. Compact servo motors facilitate the design of more agile and versatile robots, expanding their potential applications across various industries.

For a comprehensive overview of the history and development of servo motors, you can refer to this article by Control Techniques.

These developments have collectively propelled the capabilities of servo motors, solidifying their role as a cornerstone in the advancement of both industrial automation and humanoid robotics.

3. Emerging Trends in Servo Motor Technology

3.1 AI Integration

a. Smarter Motion Control

The integration of artificial intelligence (AI) into servo motor systems has revolutionized motion control, enabling real-time adaptability to dynamic environments. AI algorithms process data from various sensors, allowing servo motors to adjust their operations for optimal performance. For instance, FANUC’s AI Feed Forward technology utilizes machine learning to minimize mechanical vibrations during acceleration and deceleration, enhancing machining quality.

b. Predictive Maintenance

AI-driven predictive maintenance has become a cornerstone in modern servo motor management. By analyzing operational data, AI models can detect anomalies and predict potential failures before they occur. FANUC’s AI Servo Monitor exemplifies this approach by using deep learning to monitor torque data, identifying deviations from normal states to facilitate timely maintenance.

3.2 Energy Efficiency and Sustainability

a. Low-Power Designs

Advancements in servo motor design focus on reducing energy consumption without compromising performance. Innovations such as direct drive technology eliminate mechanical transmission components, leading to higher efficiency and lower operational costs.

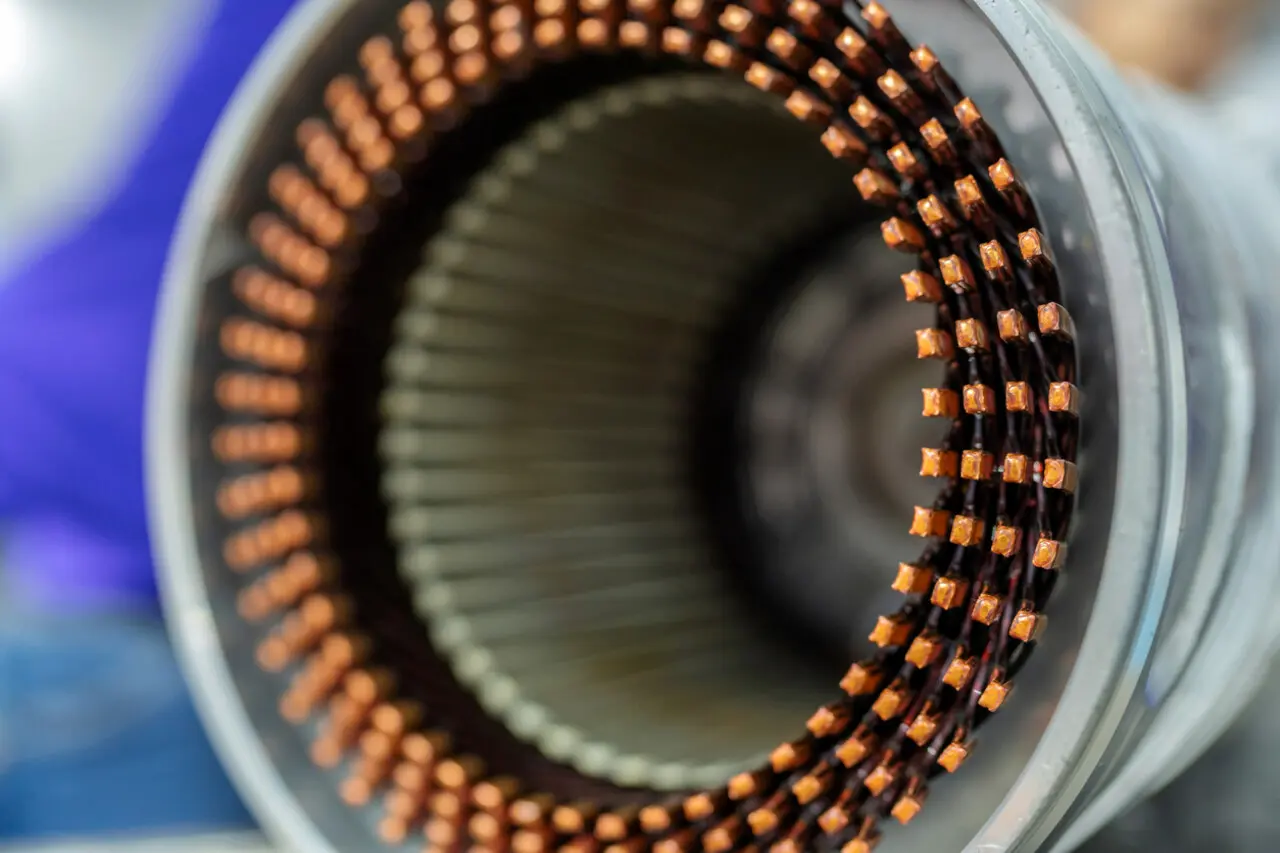

3.3 Enhanced Torque and Load Capabilities

a. Compact High-Torque Designs

Recent innovations have produced servo motors that deliver higher torque in more compact forms. For example, Mitsubishi Electric’s servo systems achieve speeds up to 6,700 rpm with compact amplifiers, enhancing performance without increasing size.

b. Applications in Heavy-Duty Robotics

These high-torque, compact servo motors are pivotal in heavy-duty robotics, enabling machines to perform tasks such as lifting and moving heavy objects with precision. Their enhanced load capabilities expand the potential applications of humanoid robots in industrial settings, improving efficiency and safety.

These emerging trends highlight the ongoing evolution of servo motor technology, driven by AI integration, sustainability efforts, and the demand for higher performance in increasingly compact designs.

4. Future Innovations in Servo Motor Technology

4.1 Modular Servo Systems

a. Flexible Configurations

The development of modular servo systems has the potential to significantly impact robotic design. These systems may allow for the customization of servo motors to better meet specific application needs. Engineers might combine different modules—such as torque, speed, or control units—to create tailored servo motor setups for diverse robotic tasks. This flexibility could reduce design complexity, potentially making it easier to implement servo motors across various industries, from consumer robotics to advanced manufacturing.

b. Simplified Maintenance

Modular servo systems may also streamline maintenance and repairs. With interchangeable components, technicians could replace faulty modules without disassembling the entire motor, potentially reducing downtime and costs. This feature might make modular designs particularly valuable in environments where uptime is critical, such as healthcare and logistics robotics.

4.2 Wireless Servo Motors

a. Freedom in Design

Wireless servo motor technology aims to eliminate the need for traditional wiring, offering greater design freedom and potentially reducing system weight. This innovation could be especially beneficial for humanoid robots, where complex wiring might hinder mobility. Additionally, wireless motors may simplify assembly and enhance scalability, facilitating the expansion of robotic systems for new functionalities.

b. Implications for Autonomous Robots

The benefits of wireless servo motors could extend to autonomous robots, enabling smoother and more adaptive navigation. Without physical wiring constraints, robots might achieve better range of motion and higher degrees of freedom, which are critical for applications like disaster response or exploration robotics. However, challenges such as ensuring reliable wireless communication and managing power consumption will need to be addressed.

4.3 Hybrid Power Systems

a. Combining Electric and Hydraulic Systems

Hybrid servo motors aim to merge the efficiency of electric systems with the high power output of hydraulic systems. This combination could enable robots to perform tasks requiring both precision and significant force, such as industrial lifting or operations in extreme environments. Nevertheless, integrating these two power sources may present engineering challenges and require careful design considerations.

b. Enhanced Performance in Extreme Environments

These hybrid systems may excel in challenging conditions, including underwater operations or high-temperature industrial settings. By leveraging the strengths of both power sources, hybrid servo motors could expand the operational capabilities of humanoid robots, paving the way for new applications. It is important to consider the durability and maintenance requirements of such systems in extreme environments.

Future innovations in servo motor technology, including modular designs, wireless systems, and hybrid power solutions, hold promise for enhancing the performance, adaptability, and efficiency of humanoid robots. While these advancements could drive progress across various industries, ongoing research and development are essential to address potential challenges and fully realize their benefits.

5. Conclusion

5.1 Recap of Key Insights

a. Trends Transforming Servo Motors

Servo motor technology is undergoing transformative changes driven by advancements in artificial intelligence, energy efficiency, and hybrid systems. AI integration allows servo motors to dynamically adapt to their environments, enhancing their responsiveness and precision. Energy-efficient designs, such as low-power motors and recyclable materials, align with sustainability goals while maintaining high performance. Hybrid power systems combine the strengths of electric and hydraulic technologies, enabling robots to tackle tasks requiring both precision and force. Together, these trends are shaping the next generation of servo motors, elevating their capabilities in both humanoid and industrial robotics.

b. Innovations Driving the Future of Robotics

Servo motors are at the forefront of robotic innovation, empowering humanoid robots to achieve unprecedented levels of functionality. Modular designs offer customizable solutions, while wireless technology enhances robot mobility and scalability. Compact, high-torque motors facilitate the creation of agile yet powerful robots, expanding their potential applications in healthcare, logistics, and manufacturing. As technology continues to evolve, servo motors will play a critical role in enabling robots to operate with greater efficiency, precision, and versatility.

5.2 Final Thoughts

Servo motor advancements represent a cornerstone in the evolution of humanoid robotics, enabling machines to perform complex tasks with human-like precision and adaptability. These innovations pave the way for robots that seamlessly integrate into various aspects of daily life, from assisting in homes and hospitals to performing high-precision industrial operations. By bridging the gap between mechanical engineering and intelligent automation, servo motors unlock the full potential of robotics, driving progress that enhances productivity, safety, and quality of life. As the robotics field advances, servo motors will continue to be an essential driver of innovation, shaping the future of human-robot collaboration.