1. Introduction

1.1 Urban Mobility Challenges and the Need for Efficient Solutions

As urbanization accelerates worldwide, cities face unprecedented challenges in managing the flow of people. By 2050, over 68% of the global population is expected to live in urban areas, intensifying the demand for efficient urban mobility solutions. Vertical transportation—such as elevators and escalators—plays a critical role in managing this influx, particularly in high-density environments where space constraints necessitate upward expansion. Smart cities, focused on integrating technology with infrastructure, depend heavily on these systems for daily operations in office buildings, residential complexes, transport hubs, and malls.

However, the rising energy costs and the need to reduce carbon emissions highlight the importance of improving efficiency in these systems. As a result, there is a significant push to modernize the technology behind elevators and escalators. The use of advanced electric motor cores is a key part of this transformation, providing a more energy-efficient solution while also ensuring reliability and smooth performance under heavy loads.

1.2 The Importance of Electric Motor Cores in Urban Transportation Systems

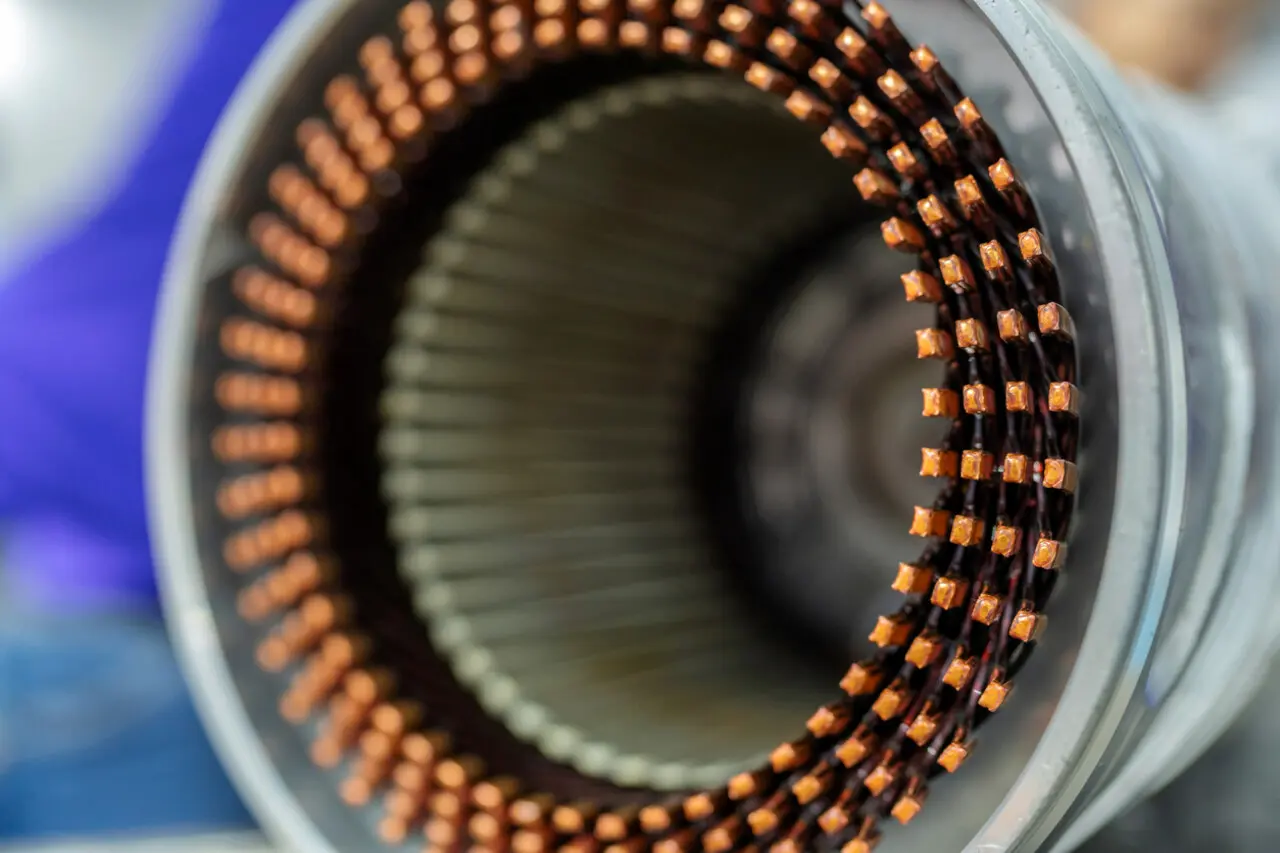

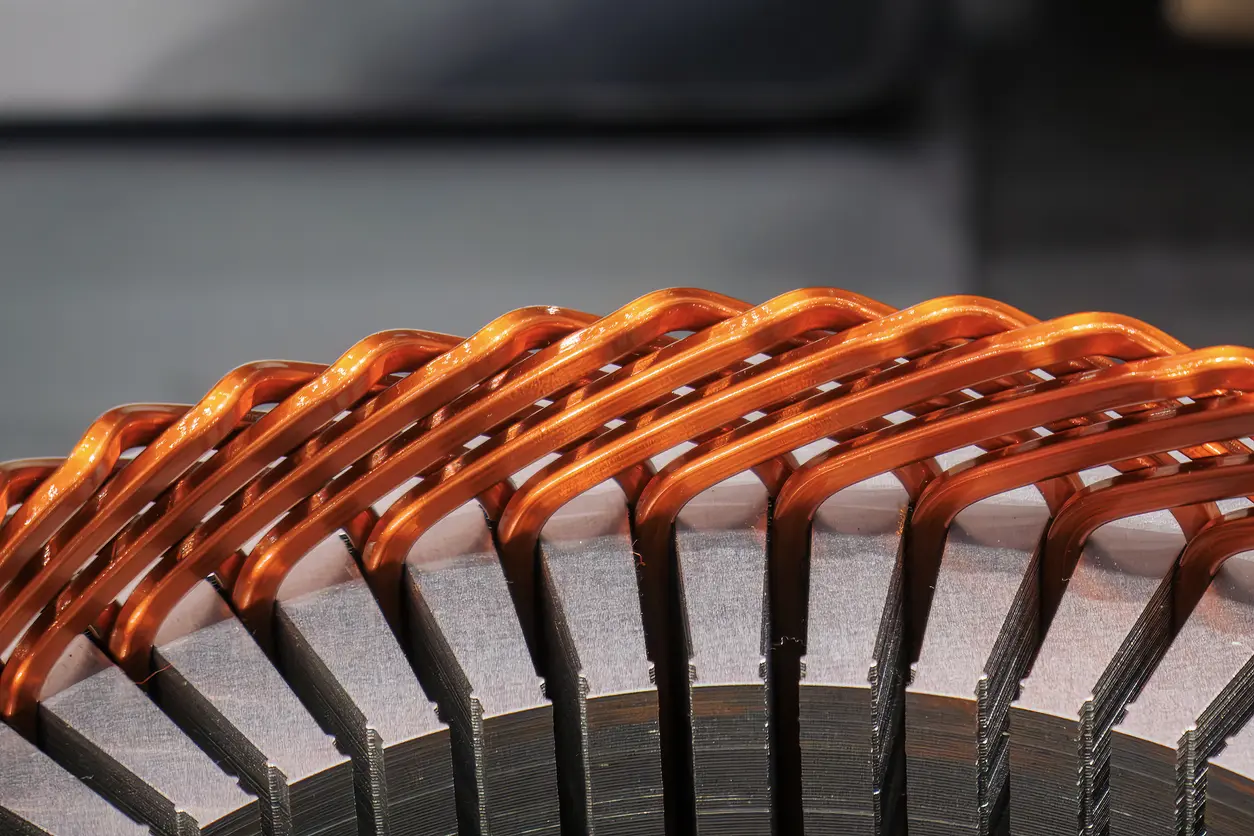

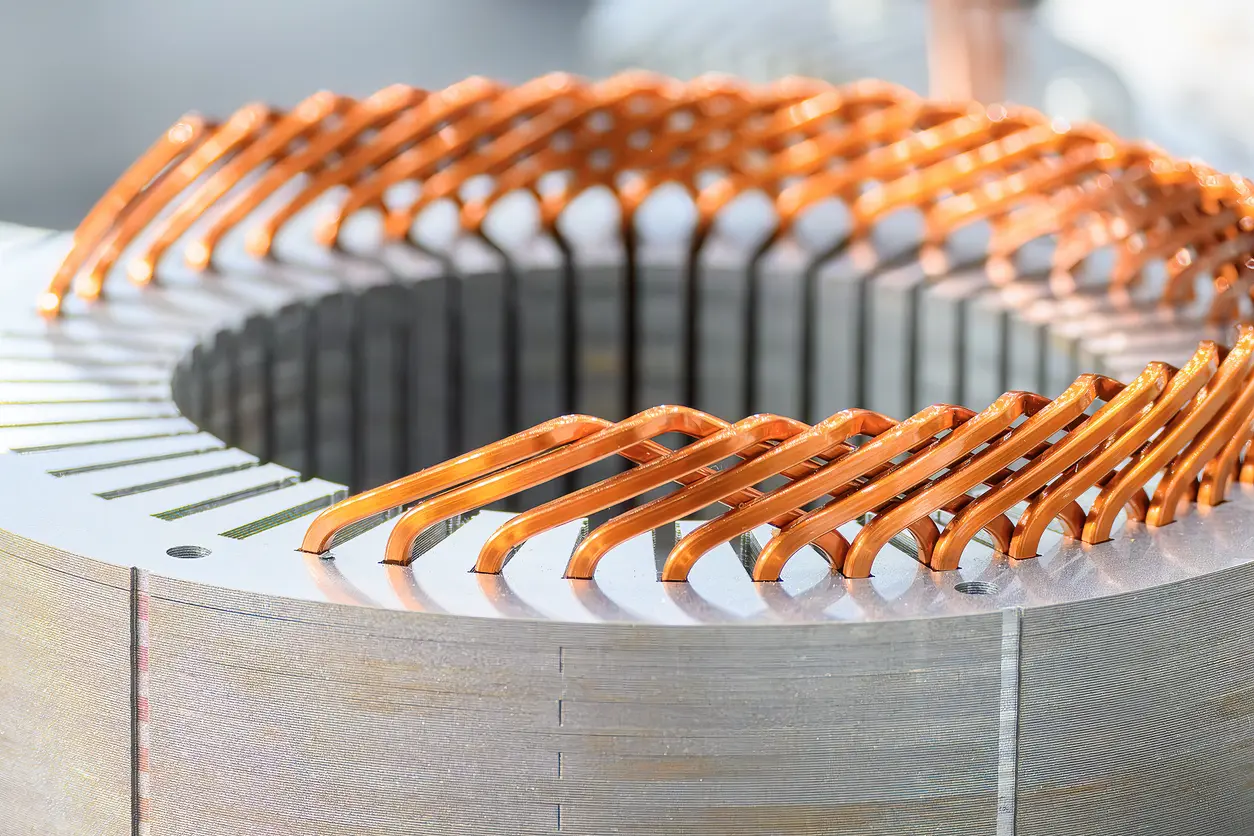

Electric motors are the backbone of modern vertical transportation systems, and at the heart of these motors lies the electric motor core. The core consists of laminated steel sheets stacked together, often designed to minimize energy losses (hysteresis and eddy currents), while improving torque and power efficiency. As cities grow taller and more complex, these cores are increasingly vital in ensuring that elevators and escalators meet the demands of high traffic without excessive energy consumption.

Optimized motor cores help significantly reduce energy wastage, increase longevity, and improve overall performance. These improvements are particularly important in smart buildings that aim for net-zero energy consumption, where every system needs to operate as efficiently as possible. Additionally, high quality motor cores contribute to reducing noise and vibration, enhancing the overall user experience, especially in high-end commercial buildings.

2. The Role of Electric Motor Cores in Elevators

2.1 How Electric Motor Cores Improve Elevator Systems

As urban environments expand vertically, the demand for efficient and reliable elevator systems has never been greater. Central to the performance of modern elevators’ electric motors is the electric motor core, which influences the system’s energy consumption, operational efficiency, and durability. Electric motor cores are designed to reduce energy losses and optimize the torque required for the smooth movement of elevator cabins, even under heavy loads. In this context, advanced motor core technologies play a critical role in improving energy efficiency, which is particularly important in high-rise buildings where elevators are constantly in use.

By utilizing optimized motor cores with improved magnetic properties, elevators can achieve noticeable reductions in energy consumption. These cores are specifically engineered to minimize hysteresis and eddy current losses, which are common inefficiencies in traditional electric motors. This improvement allows building operators to significantly lower operational costs while contributing to a more sustainable urban environment.

2.2 Case Studies: Smart City Elevators Powered by Advanced Electric Motor Cores

In smart cities around the world, we see advanced elevator systems utilizing cutting-edge electric motor cores to meet the demands of energy efficiency and sustainability. For instance, buildings in major urban centers such as New York and Singapore have adopted elevators with high-efficiency motor cores, significantly reducing their carbon footprints while enhancing the performance and reliability of the systems.

A notable example is the One World Trade Center in New York, which incorporates state-of-the-art elevator systems powered by highly efficient electric motors with advanced cores. These systems contribute to the building’s overall sustainability objectives by optimizing energy use, reducing downtime, and providing a smoother, quieter experience for occupants.

As the need for energy-efficient infrastructure grows, motor core technology continues to evolve, playing a pivotal role in the development of next-generation elevators. These innovations not only improve building efficiency but also align with broader global sustainability goals, ensuring that cities of the future can grow vertically without compromising on energy consumption or environmental impact.

3. The Role of Electric Motor Cores in Escalators

3.1 Enhancing Performance and Durability in Escalator Systems

In high-traffic areas like shopping malls, airports, and metro stations, escalators are a crucial element of urban mobility. These systems rely heavily on the efficiency and durability of their electric motors to provide consistent service while minimizing energy consumption. Electric motor cores play a pivotal role in achieving these goals by improving both the performance and longevity of escalator motors.

Advanced motor cores, often made from specialized laminated steel, reduce energy losses caused by hysteresis and eddy currents. This not only enhances the energy efficiency of the motor but also minimizes heat generation, which can be a major cause of wear and tear in mechanical systems. As a result, escalators equipped with optimized motor cores experience less downtime, require fewer repairs, and ultimately lead to lower maintenance costs. This is especially valuable in environments where escalators are operational around the clock and need to withstand heavy usage.

Moreover, the smooth operation provided by these cores ensures a quieter, more comfortable ride for users, which is particularly important in public transportation hubs. By enhancing motor performance and durability, electric motor cores are helping to shape a future where escalators can handle increased urban demand with improved efficiency.

3.2 Innovations in Escalator Systems Using Electric Motor Cores

Modern escalator systems are benefiting from several innovations driven by advanced electric motor core technology. One such innovation is the development of smart escalators that adapt their speed based on real-time traffic. When traffic is light, these escalators can slow down or enter standby mode, drastically reducing energy consumption. This type of dynamic operation is made possible by the efficiency of the motor core, which can quickly respond to changes in demand without sacrificing performance.

Additionally, escalators with regenerative braking systems, which recover energy during operation, are becoming more common in smart cities. This energy can be fed back into the grid or used to power other systems within the building, contributing to overall energy savings. Electric motor cores are essential in these systems, providing the necessary efficiency and performance to make energy recovery viable.

These innovations demonstrate how electric motor cores are pushing the boundaries of what escalator systems can achieve, not only in terms of performance but also in sustainability and energy conservation.

4. Motor Core Efficiency and AI Synergy

4.1 Reducing Energy Consumption and Environmental Impact

One of the most significant advantages of using advanced electric motor cores in vertical transportation systems like elevators and escalators is the reduction in energy consumption, which directly translates to lower environmental impact. Motor cores made from high-performance materials are designed to minimize energy losses by reducing eddy currents and hysteresis. This increases the overall efficiency of the motor, which is critical in systems that operate continuously in high-traffic urban environments.

In smart buildings and cities, where sustainability is a key goal, reducing energy usage in vertical transportation systems helps in achieving global carbon reduction targets. For example, advanced elevator systems with optimized motor cores can consume significantly less electricity during peak hours compared to conventional systems. Over time, these savings contribute to a building’s energy efficiency, often helping it achieve green certifications such as LEED (Leadership in Energy and Environmental Design).

Furthermore, many modern escalators and elevators are equipped with energy-saving features such as regenerative braking systems. These systems convert the energy produced during descent or deceleration into electricity, which can be fed back into the building’s power grid. Electric motor cores play an essential role in these regenerative systems by enabling efficient energy transfer, further reducing the environmental impact of vertical transportation.

4.2 Contribution to the Circular Economy

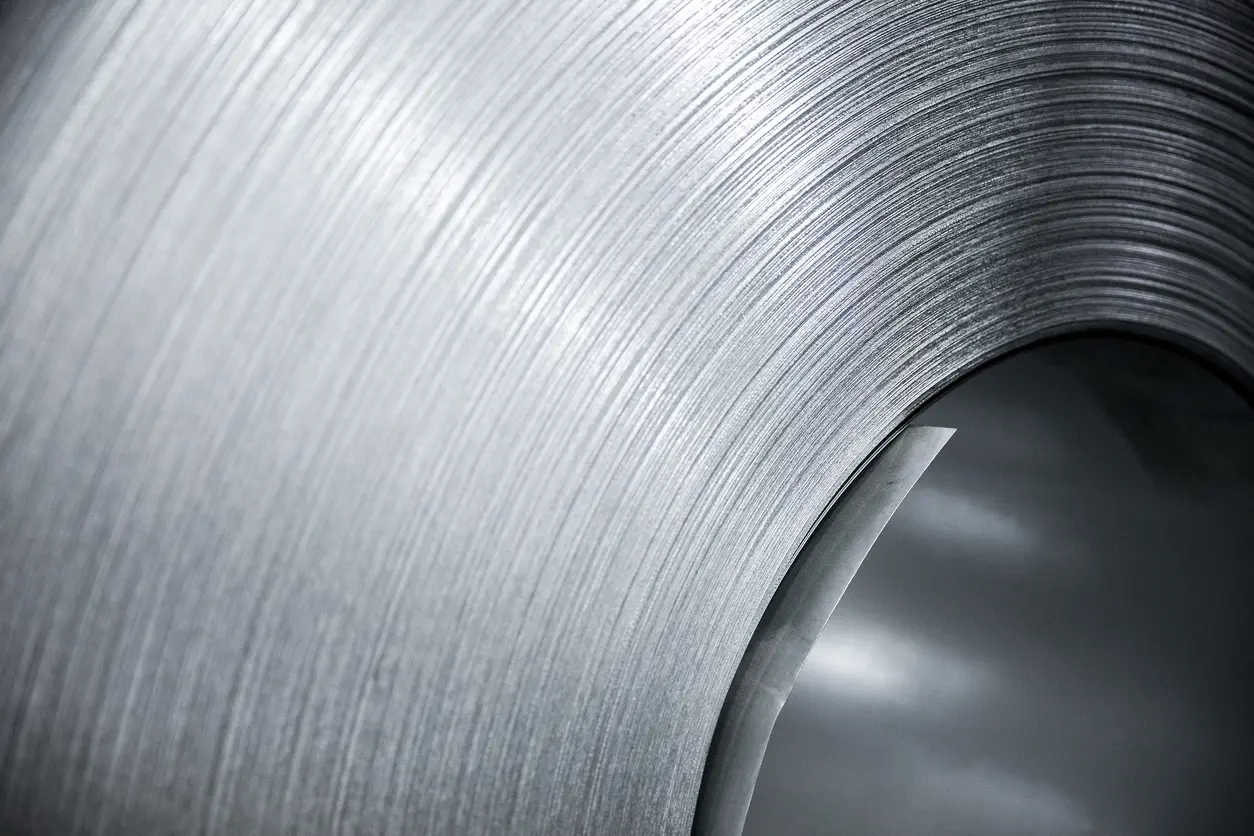

The sustainability benefits of electric motor cores extend beyond energy efficiency—they also play a vital role in supporting the circular economy. Motor cores are primarily constructed from durable and recyclable materials, such as silicon steel. At the end of their lifecycle, these materials can be efficiently recycled, allowing the steel to be recovered and used in new products. This recycling process helps to minimize waste and conserves valuable resources by reducing the need for new raw materials, aligning with sustainable practices and the principles of a circular economy. While motor cores are generally dismantled for material recovery rather than being directly repurposed, the ability to recycle their components significantly contributes to resource conservation.

Additionally, advanced motor cores are designed for longevity, meaning they last longer before requiring replacement or major repairs. This extends the overall life of vertical transportation systems, reducing the frequency of manufacturing new components and further lowering the environmental footprint. By designing electric motor cores with both performance and sustainability in mind, manufacturers contribute to a more circular and resource-efficient economy, aligning with global sustainability trends.

5. Future Trends in Electric Motor Core Technology for Urban Mobility

5.1 Advances in Motor Core Materials and Design

As technology advances, so do the materials and design principles behind electric motor cores, significantly impacting the efficiency and performance of vertical transportation systems such as elevators and escalators. A notable trend is the utilization of high-performance materials that offer lower core losses compared to traditional silicon steel, thereby enhancing energy efficiency. The adoption of these advanced materials enables motor cores to minimize energy wastage due to hysteresis and eddy currents, making them particularly suitable for systems requiring continuous operation in high-traffic buildings.

Another significant trend is the miniaturization of motor cores, which improves power density without sacrificing efficiency. This development allows electric motors to become smaller and lighter, facilitating their integration into compact, modern designs for elevators and escalators. This is especially critical in urban environments where space optimization is a priority. Additionally, the move toward modular motor core designs enables faster manufacturing and maintenance processes, contributing to reduced operational costs.

5.2 The Impact of IoT and AI on Vertical Transportation Systems

The integration of IoT and AI is revolutionizing vertical transportation, enhancing both efficiency and reliability. Although electric motor cores are passive components, they play a crucial role in supporting these advancements by ensuring efficient motor performance.

IoT sensors monitor key data such as energy consumption, motor temperature, and overall system health. AI-powered predictive maintenance uses this data to identify inefficiencies in motor cores, allowing for early intervention before failures occur. This helps extend the lifespan of motors and reduces downtime.

AI also optimizes energy usage by adjusting elevator and escalator operations based on real-time demand. For example, smart elevators can reduce speed or enter standby mode during low-traffic periods, minimizing energy consumption. In systems utilizing regenerative braking, efficient motor cores help recover energy during deceleration, contributing to the building’s sustainability.

By enabling smarter operations, IoT and AI, combined with high-performance motor cores, are driving more efficient, reliable, and eco-friendly vertical transportation in modern cities.

6. Conclusion

6.1 The Key Role of Electric Motor Cores in the Future of Urban Mobility

Electric motor cores are pivotal in shaping the future of urban mobility, particularly in vertical transportation systems such as elevators and escalators. As cities continue to grow and vertical infrastructure becomes more critical, the demand for energy-efficient and reliable transportation solutions will only increase. Electric motor cores, made from high-performance materials, ensure that these systems operate efficiently, minimizing energy losses and enhancing durability.

With the rise of smart cities, where sustainability and connectivity are paramount, advanced motor cores enable elevators and escalators to meet higher standards of performance. These components reduce operational costs by lowering energy consumption and improving system longevity, ensuring that urban infrastructure can keep pace with the evolving needs of dense urban environments.