1. Introduction

1.1 Importance of Precision in Medical Equipment

Precision motors play a crucial role in the functionality of modern medical equipment. Their importance is underscored by the need for accuracy and reliability in medical diagnoses and treatments.

a. Ensuring Accurate Diagnoses

Precision in medical equipment is vital for ensuring accurate diagnoses. Advanced imaging devices, such as MRI and CT scanners, rely on precision motors to produce clear and accurate images. Any deviation in motor performance can result in blurred images or incorrect data, leading to misdiagnosis. By utilizing high-quality precision motors, medical professionals can trust the results generated by these machines, ensuring that patients receive the correct diagnosis and appropriate treatment.

b. Enhancing Patient Safety

In addition to accurate diagnoses, precision motors enhance patient safety. Surgical robots, for example, require exceptional motor precision to perform delicate procedures with minimal invasiveness. Precision motors ensure that surgical tools are accurately positioned and movements are controlled, reducing the risk of complications and improving surgical outcomes.

2. Types of Medical Equipment Utilizing Precision Motors

2.1 Surgical Robots

Surgical robots represent one of the most significant advancements in medical technology, and precision motors are at the heart of their functionality.

a. Role of Precision Motors in Surgery

In surgical robots, precision motors enable the precise and controlled movements required for complex surgical procedures. These motors allow for minimal invasiveness, which translates to smaller incisions, reduced blood loss, and faster recovery times for patients. Precision motors ensure that the surgical instruments can be manipulated with high accuracy, providing surgeons with enhanced dexterity and control, which is crucial for delicate operations such as neurosurgery or cardiac surgery.

b. Case Studies and Examples

For instance, the da Vinci Surgical System, a renowned robotic surgical system, relies heavily on precision motors to perform intricate surgeries. This system has been used successfully in thousands of procedures worldwide, demonstrating the critical role of precision motors in achieving high success rates and patient satisfaction. Another example is the MAKO system used for orthopedic surgery, which employs precision motors to assist in joint replacement surgeries, ensuring accurate alignment and positioning of implants.

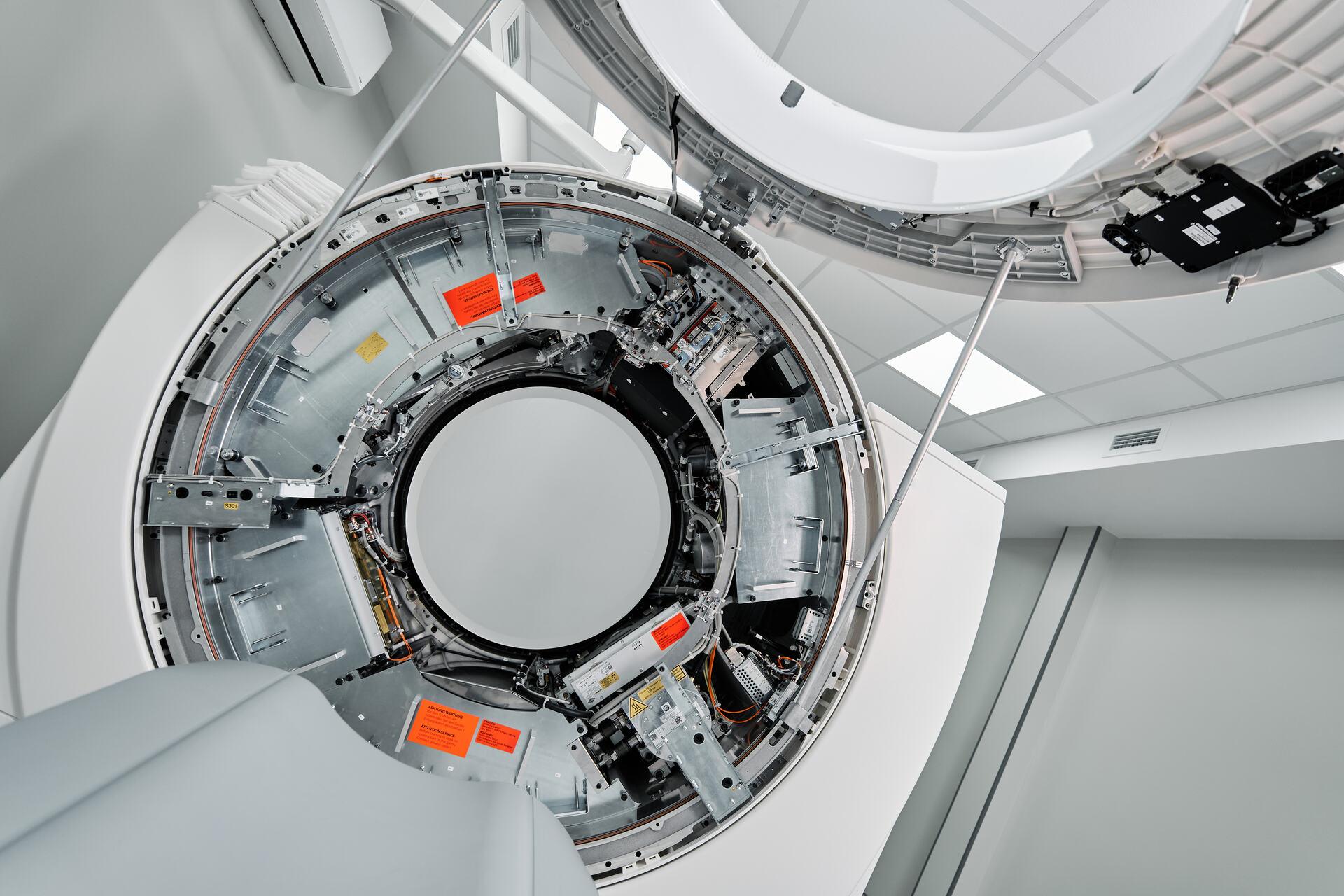

2.2 Diagnostic Imaging Equipment

Precision motors are also integral to the operation of diagnostic imaging equipment, which is essential for accurate diagnosis and treatment planning.

a. MRI and CT Scanners

MRI and CT scanners use precision motors to control the movement of scanning components. In MRI machines, precision motors help in the precise positioning of the magnetic coils, which is crucial for obtaining high-resolution images of internal body structures. Similarly, in CT scanners, precision motors ensure the accurate rotation of the X-ray source and detectors around the patient, resulting in detailed cross-sectional images.

3. Key Features of Precision Motors

3.1 High Accuracy and Stability

Precision motors are known for their high accuracy and stability, which are essential features in medical equipment.

a. Maintaining Consistency

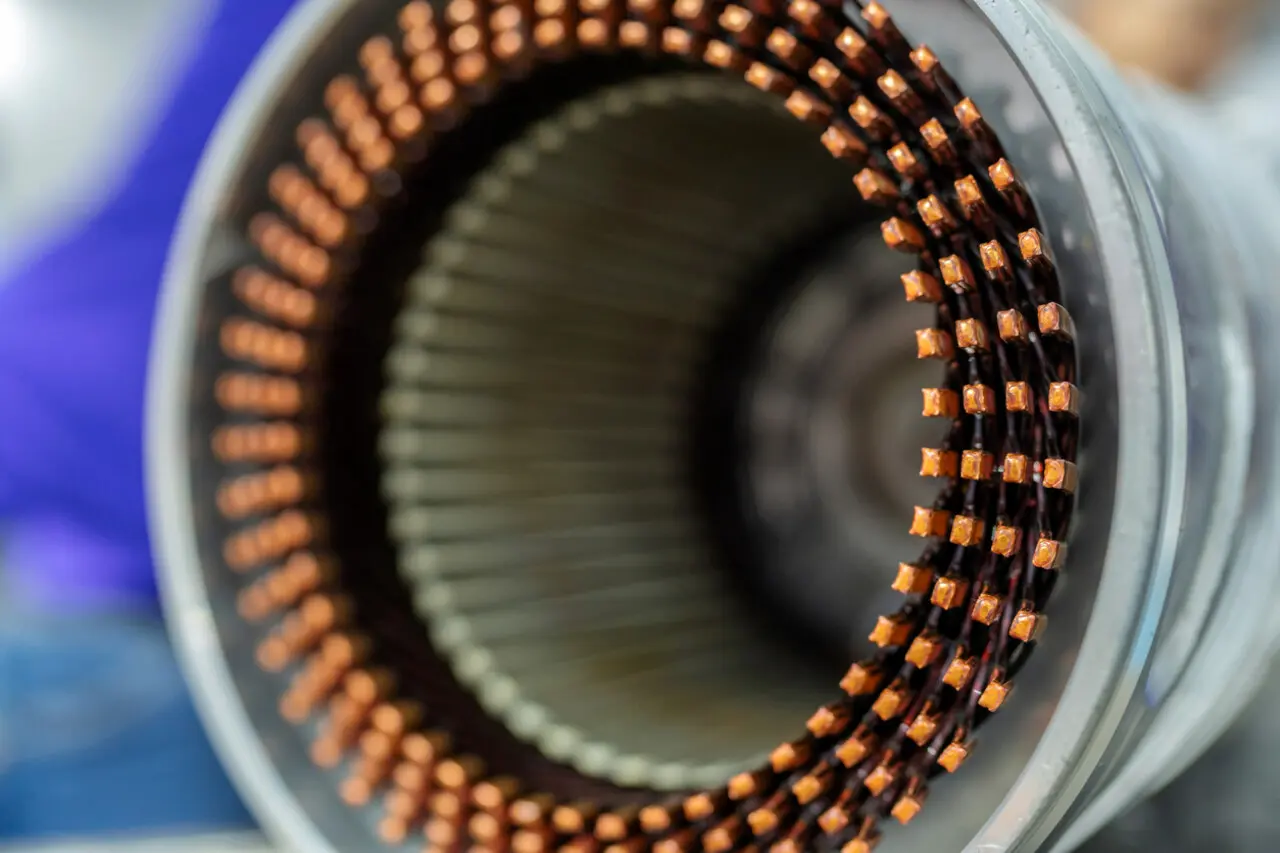

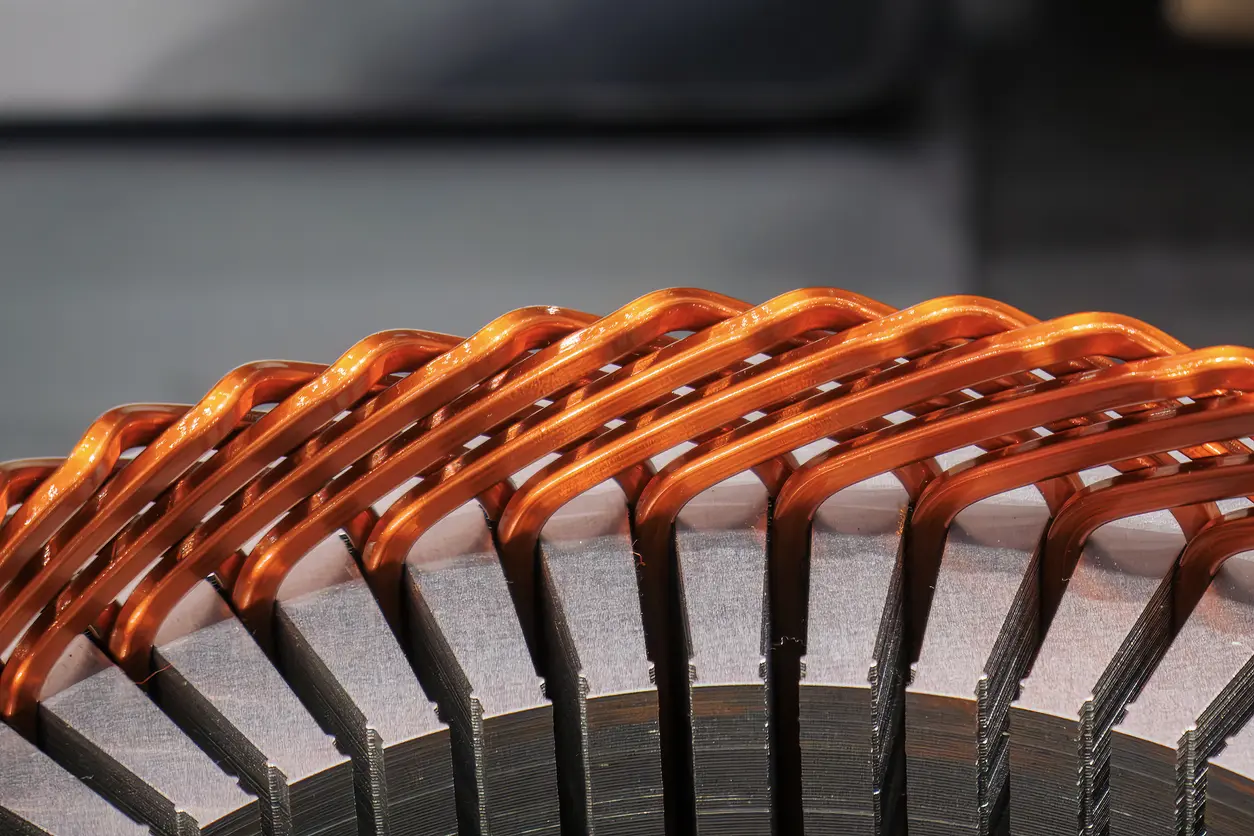

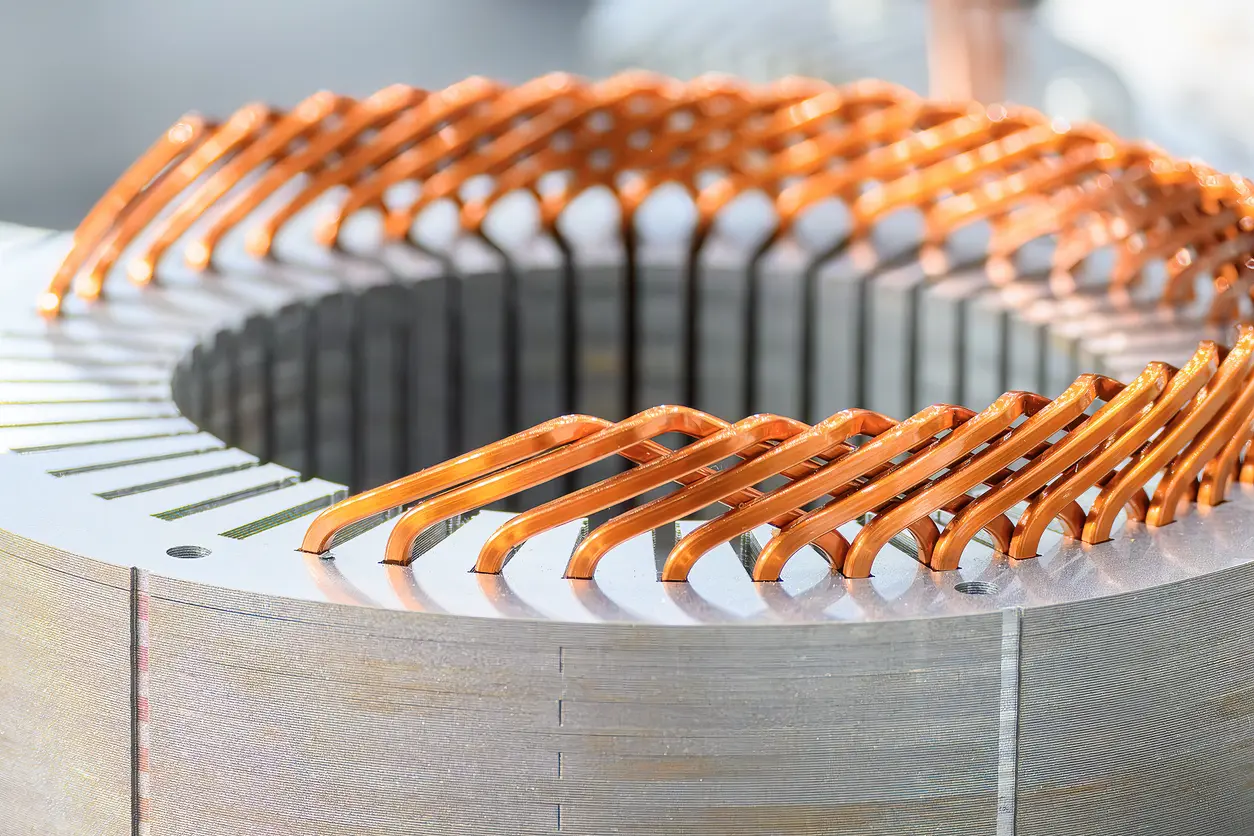

One of the primary benefits of precision motors is their ability to maintain consistent performance over time. High-quality motor core lamination plays a crucial role in this consistency. By reducing energy loss and heat generation, these laminations ensure that the motor operates smoothly and reliably. In medical applications, where even minor deviations can have significant consequences, the consistent performance of precision motors ensures that equipment functions as intended, providing accurate and repeatable results.

b. Reducing Errors

The high accuracy of precision motors also contributes to reducing errors in medical procedures and diagnostics. For example, in imaging equipment, precision motors enable the exact positioning of components, resulting in clear and precise images. This accuracy helps in diagnosing medical conditions accurately and planning appropriate treatments. In surgical robots, precise motor control minimizes the risk of accidental movements, enhancing patient safety and surgical outcomes.

3.2 Durability and Reliability

Durability and reliability are other critical features of precision motors in medical equipment.

a. Long Lifespan

Precision motors are designed to have a long lifespan, which is essential for medical devices that need to operate continuously or for extended periods. The quality of motor core lamination significantly affects the motor’s lifespan. High-quality laminations reduce wear and tear, ensuring that the motor can withstand the demanding conditions of medical applications without frequent replacements.

b. Minimal Maintenance

In addition to a long lifespan, precision motors require minimal maintenance. This reliability is crucial in medical settings, where equipment downtime can disrupt patient care. By using durable materials and advanced manufacturing techniques, precision motors can operate efficiently with minimal maintenance, reducing the overall cost of ownership and ensuring that medical devices are always ready for use.

3.3 Energy Efficiency

Energy efficiency is another important feature of precision motors, particularly in the context of medical equipment.

a. Lower Power Consumption

Precision motors are designed to consume less power while delivering high performance. This energy efficiency is particularly beneficial in medical equipment, which often operates continuously. Lower power consumption reduces operating costs and contributes to a greener, more sustainable healthcare environment.

4. Advancements in Precision Motor Technology

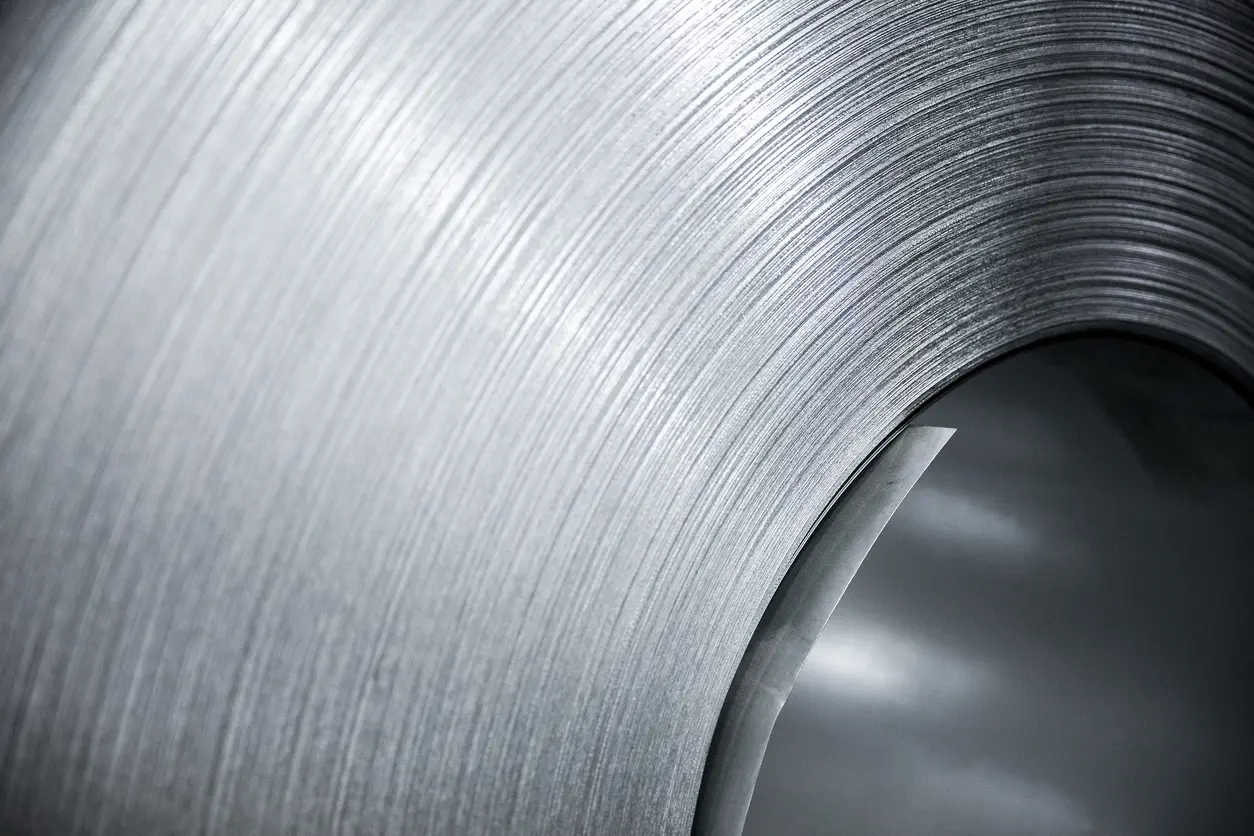

4.1 Material Innovations

Recent advancements in material science have significantly enhanced the performance and reliability of precision motors used in medical equipment.

a. High-Performance Alloys

The development of high-performance alloys has been a major breakthrough in precision motor technology. These alloys offer superior strength, durability, and thermal stability compared to traditional materials. For instance, using high-performance alloys in motor cores can reduce heat generation and improve efficiency, which is crucial for medical devices that require sustained, reliable operation. These materials also allow for lighter and more compact motor designs, enhancing the portability and usability of medical equipment such as portable ultrasound machines and wearable monitoring devices.

b. Improved Insulation Techniques

Advancements in insulation techniques have also played a critical role in enhancing the performance of precision motors. Improved insulation materials can withstand higher temperatures and offer better electrical insulation, reducing the risk of short circuits and improving overall motor longevity. These improvements are particularly important in medical applications where motor reliability and safety are paramount.

4.2 Smart Control Systems

The integration of smart control systems with precision motors has revolutionized the functionality and efficiency of medical equipment.

a. Integration with AI

Integrating artificial intelligence (AI) with precision motors has opened up new possibilities for automation and intelligent control in medical devices. AI algorithms can analyze real-time data and adjust motor performance dynamically, optimizing efficiency and accuracy. In surgical robots, AI-driven motors can assist surgeons with precise movements, reducing the risk of human error and improving surgical outcomes. This level of control and adaptability is transforming how complex medical procedures are performed, making them safer and more efficient.

b. Real-Time Monitoring and Adjustments

Real-time monitoring and adjustment capabilities are another significant advancement in precision motor technology. Modern precision motors are equipped with sensors that continuously monitor their performance and health. These sensors can detect anomalies and make real-time adjustments to maintain optimal operation. For example, in devices like infusion pumps and ventilators, precision motors with real-time monitoring ensure consistent and accurate operation, providing critical data to healthcare providers without interruption. This capability enhances the reliability of medical devices and ensures they can respond promptly to any changes in patient condition. However, in patient monitoring systems that track vital signs, the reliance is more on advanced sensors and microelectronics rather than precision motors.

5. Conclusion

5.1 Summary of Benefits

a. Enhanced Performance of Precision Motors in Medical Devices

Precision motors significantly boost the functionality of medical devices. Their high accuracy is crucial for diagnostic tools like MRI and CT scanners, which rely on precise control to generate clear images necessary for accurate diagnosis and treatment planning. Brushless DC and stepper motors are essential for the precise movements these imaging systems require.

In surgical applications, precision motors are indispensable. Systems like the da Vinci Surgical System depend on these motors to perform complex, minimally invasive procedures. This reliance enhances surgical precision, reduces errors, and leads to quicker patient recovery.

b. Importance of High-Quality Lamination Motor Cores

Implementing high-quality lamination motor cores is vital for achieving exceptional precision in motors. These laminations reduce energy loss and heat generation, ensuring smooth and reliable performance. Consistency is crucial in medical settings where precision is paramount. Additionally, high-quality laminations minimize wear and tear, maintaining motor performance over time.

c. Future Prospects for Precision Motors in Medical Technology

The future of precision motors in medical equipment is bright. Advances in materials, such as high-performance alloys, enhance motor efficiency and durability, making them reliable for continuous use in medical settings. Innovations in smart control systems, including AI integration, are making motors more intelligent and adaptable. These advancements are expected to further improve healthcare delivery and patient care.

In summary, precision motors are crucial to modern medical equipment, providing enhanced performance and supporting advancements that will continue to elevate the quality of healthcare. By integrating high-quality lamination motor cores and leveraging the latest technological innovations, medical devices can achieve good precision and reliability.

c. Call to Action

For those in the medical equipment industry seeking high-quality motor core stamping products, our company offers cutting-edge solutions tailored to meet your needs. Our products are designed to enhance the performance and reliability of your medical devices. Contact us today to learn more about how our precision motor cores can benefit your medical equipment and support your technological advancements.

In conclusion, precision motors are vital to the functionality and advancement of medical equipment. Their ability to provide high accuracy, durability, and efficiency makes them indispensable in the healthcare industry. As technology continues to progress, precision motors will undoubtedly remain at the forefront of medical innovations, driving improvements in patient care and medical outcomes.