Introduction: 3 Main Methods and the Self-Bonding Method

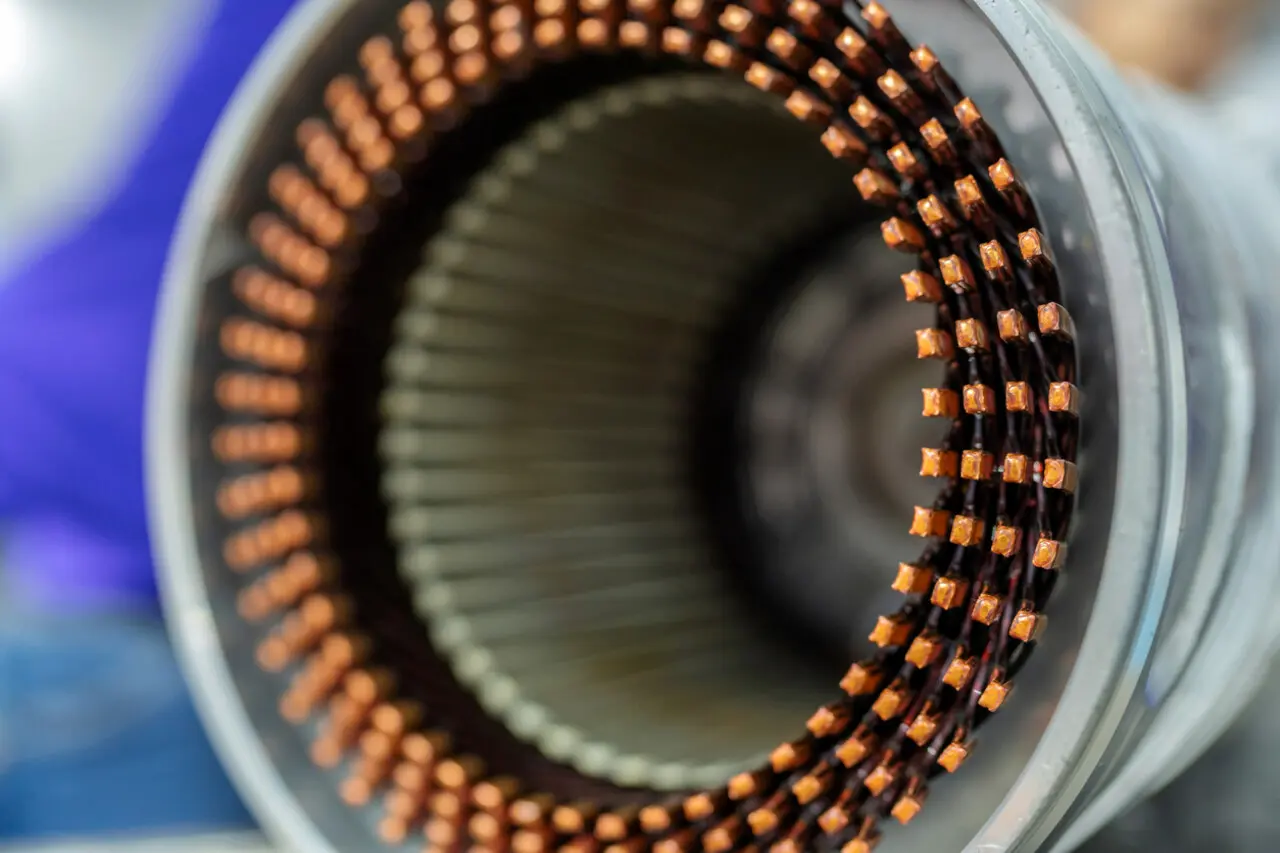

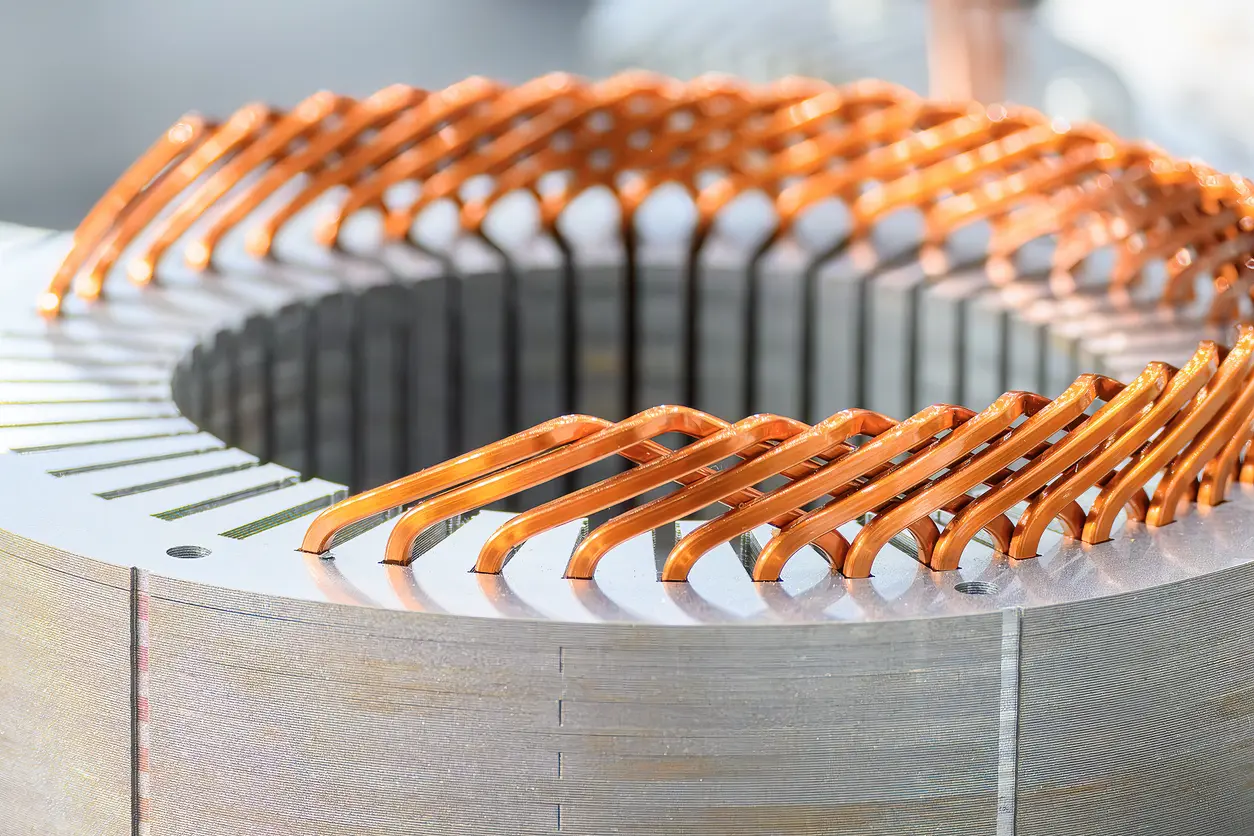

In the contemporary manufacturing of electric motor cores, the stacking of lamination sheets is predominantly performed using precision punch presses, a reliable and efficient mainstay across the industry. Within this framework, manufacturers employ several distinct sub-methods to combine individual lamination sheets into cohesive motor core stacks: interlocking, welding, and bonding methods.

Each of these techniques presents unique advantages and trade-offs. Interlocking is appreciated for its straightforward, mechanical approach that offers structural rigidity but can introduce electrical losses due to the metal-to-metal contact points. Welding provides excellent mechanical integrity and stability; however, it often results in increased thermal stress, potentially affecting magnetic performance negatively. The bonding method, particularly the self-bonding method, emerges as an innovative alternative within the bonding category. This method utilizes specially formulated adhesives pre-applied to lamination sheets, enabling them to securely bond during the stacking and heating processes.

Among these contemporary methods, the self-bonding method distinctly stands out due to its exceptional balance of structural integrity and electrical performance. Unlike interlocking or welding, the self-bonding method eliminates the mechanical and thermal stresses that can compromise motor efficiency. Additionally, the self-bonding method significantly reduces eddy current losses by minimizing conductive paths, thus enhancing the overall performance and efficiency of the motor cores. As electric motor technology advances, the self-bonding method continues to gain recognition for its capability to deliver high-quality, reliable lamination stacks optimized for modern high-performance applications.

Below we are going to explore the pros and cons of the 3 main processing method categories and show why does the self-bonding method stands out to be the leading-edge method.

Interlocking Method and its Pros and Cons

The interlocking method employed in electric motor core lamination stacking predominantly includes two types: circular interlocking and V-shape interlocking. Each variant offers distinct mechanical characteristics, rated on a three-star scale. Circular interlocking exhibits relatively low mechanical strength at one star but excels with a three-star stacking factor, indicating excellent compactness and utilization of lamination material. It earns two stars for vibration noise, denoting moderate performance, and scores one star each for heat transfer efficiency and leakage resistance, highlighting potential limitations in thermal management and sealing.

Conversely, V-shape interlocking provides improved mechanical strength, rated at two stars, offering better structural rigidity. However, it scores lower in stacking factor and vibration noise, receiving only one star each, reflecting challenges in compactness and higher noise levels during operation. Similar to circular interlocking, V-shape also achieves one star in both heat transfer and leakage tests, indicating comparable limitations in thermal efficiency and sealing capabilities.

From an electrical standpoint, both circular and V-shape interlocking methods are compromised by their riveting points. These mechanical rivets, essential for securing lamination sheets, induce mechanical stress during punching, creating short circuits between laminations. This results in elevated eddy current losses and reduced overall iron loss performance. Furthermore, these riveting-induced disruptions significantly limit magnetic flux properties by lowering the magnetic saturation threshold, thereby negatively affecting the motor’s efficiency and performance potential.

Welding Method and its Pros and Cons

The welding method represents another prevalent approach for combining laminated sheets in motor cores. It is renowned for its strong mechanical properties, receiving top ratings of three stars for both mechanical strength and stacking factor, indicating exceptional structural integrity and high material compactness. Additionally, welding achieves a moderate two-star rating for vibration noise, reflecting good, though not optimal, noise management during operation. However, its performance declines sharply in terms of heat transfer and leakage resistance, scoring only one star in both categories, highlighting considerable limitations in thermal management and sealing capability.

Electrically, the welding method presents significant drawbacks. It yields higher core losses due to the welding path’s width and depth, which induce increased thermal stress within the laminated sheets. The welding process inherently creates short circuits by blending the individual lamination layers, leading to higher eddy current losses. Nevertheless, welding exerts a relatively lower impact on magnetic flux capabilities compared to interlocking methods, thus maintaining somewhat better overall flux performance despite these drawbacks.

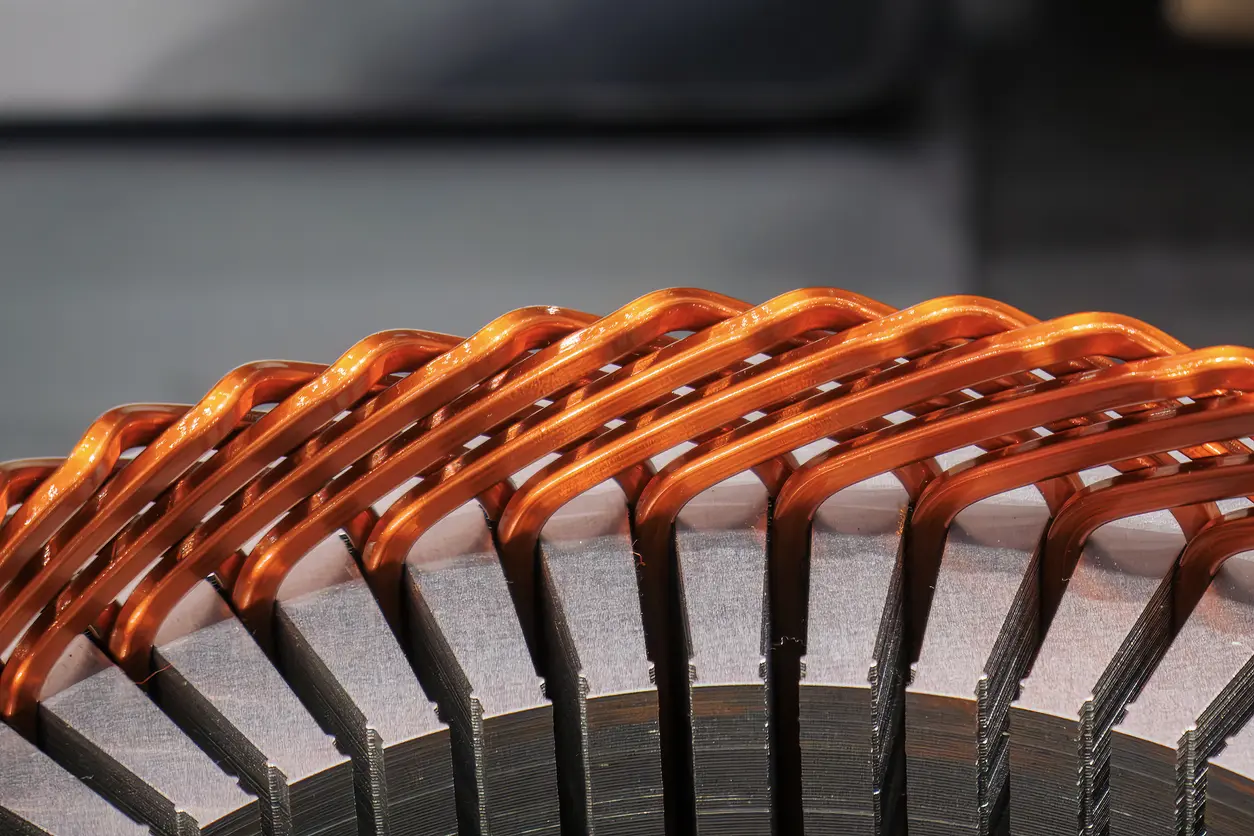

Bonding Method- Leading-Edge Self-Bonding Method

Within the bonding category, two sub-methods stand out: gluing and self-bonding. The gluing method offers balanced yet moderate mechanical characteristics, rated two stars in mechanical strength, stacking factor, vibration noise, and heat transfer, while scoring only one star in leakage resistance. This indicates satisfactory overall performance but highlights notable limitations in ensuring effective sealing against leaks.

In stark contrast, the self-bonding method represents the leading-edge technique in lamination processing. It excels significantly, scoring three stars across all evaluation metrics including mechanical strength, stacking factor, vibration noise, heat transfer, and leakage resistance. This consistent high performance makes self-bonding the preferred choice for manufacturers targeting high-performance, high-efficiency motor applications. Its capability to reduce eddy current losses, enhance structural integrity, and optimize magnetic flux sets it distinctly apart, solidifying its status as the most advanced and efficient method available in modern lamination stacking technology.

Further Reading: