Table of Contents

Introduction

Motor designers face a fundamental choice when assembling stator cores: welding, interlocking, or bonding. Each method shapes electromagnetic performance, mechanical integrity, and manufacturing requirements. Recent industry data shows a notable shift toward bonded stator core assembly, particularly in high-performance applications where efficiency and noise control cannot be compromised.

This technical analysis examines the engineering advantages driving bonded stator core adoption across industries from automotive to aerospace. We’ll explore the quantifiable performance differences, manufacturing considerations, and application-specific benefits that make bonding the preferred choice for demanding motor applications.

The stakes are significant. Assembly method selection directly impacts core losses, thermal management, and acoustic performance—parameters that determine whether a motor meets increasingly stringent efficiency regulations and customer expectations for quiet operation.

The Shift Beyond Traditional Stator Assembly

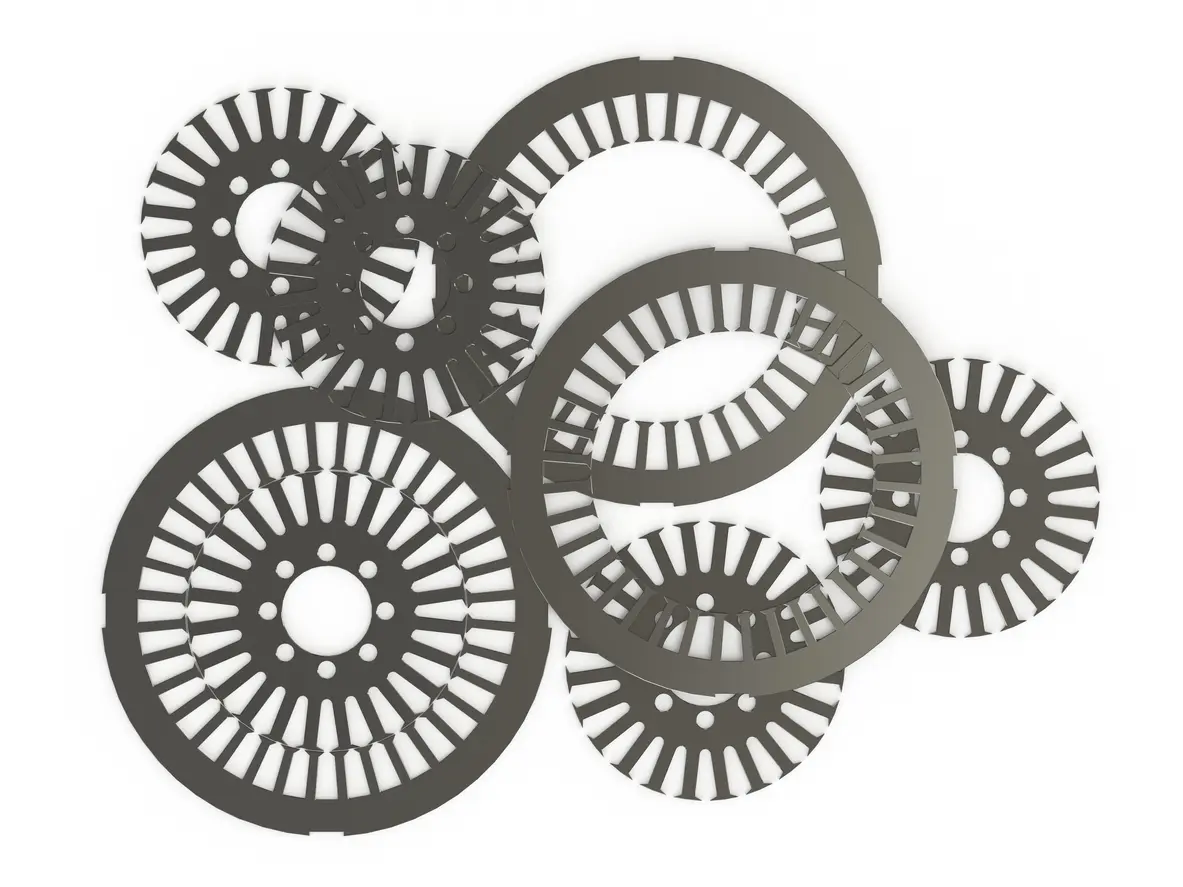

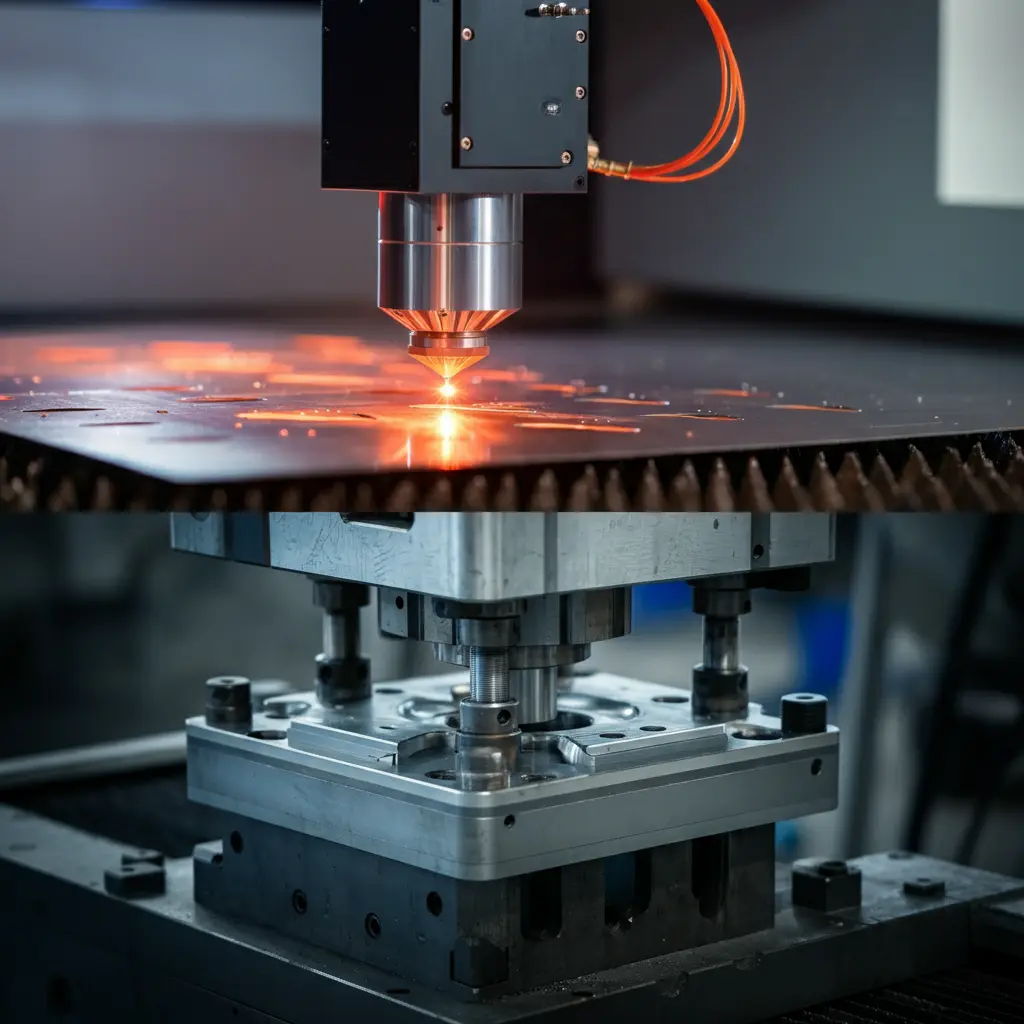

Traditional stator assembly methods have served the industry for decades. Welding creates strong metallurgical bonds by melting lamination edges at specific points through TIG and laser welds, while interlocking uses mechanical tabs stamped into individual laminations to create stack cohesion. Both approaches offer proven manufacturing processes and established cost structures.

However, these conventional methods carry inherent limitations. Welding necessarily compromises the electrical isolation between laminations—the fundamental principle behind laminated construction. Interlocking requires specific geometric features that constrain design flexibility and can introduce mechanical noise under vibrational loads.

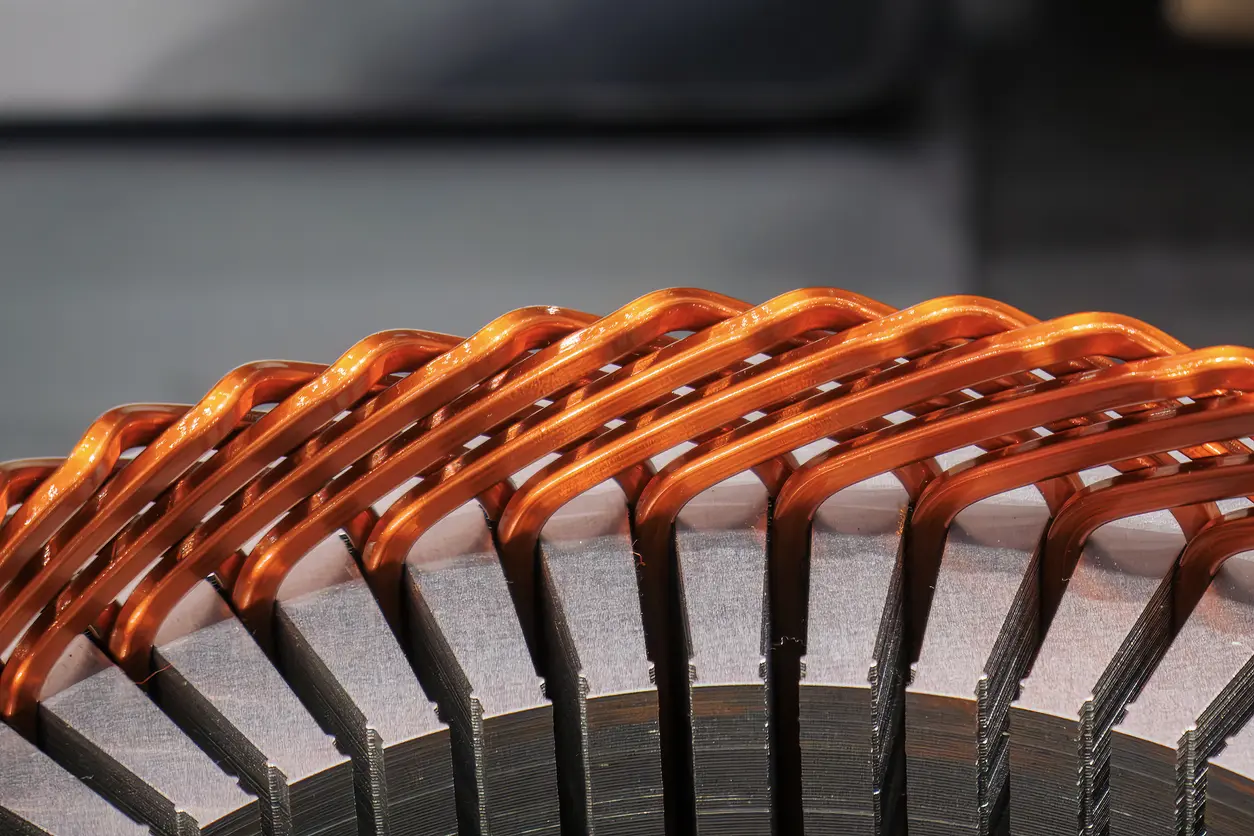

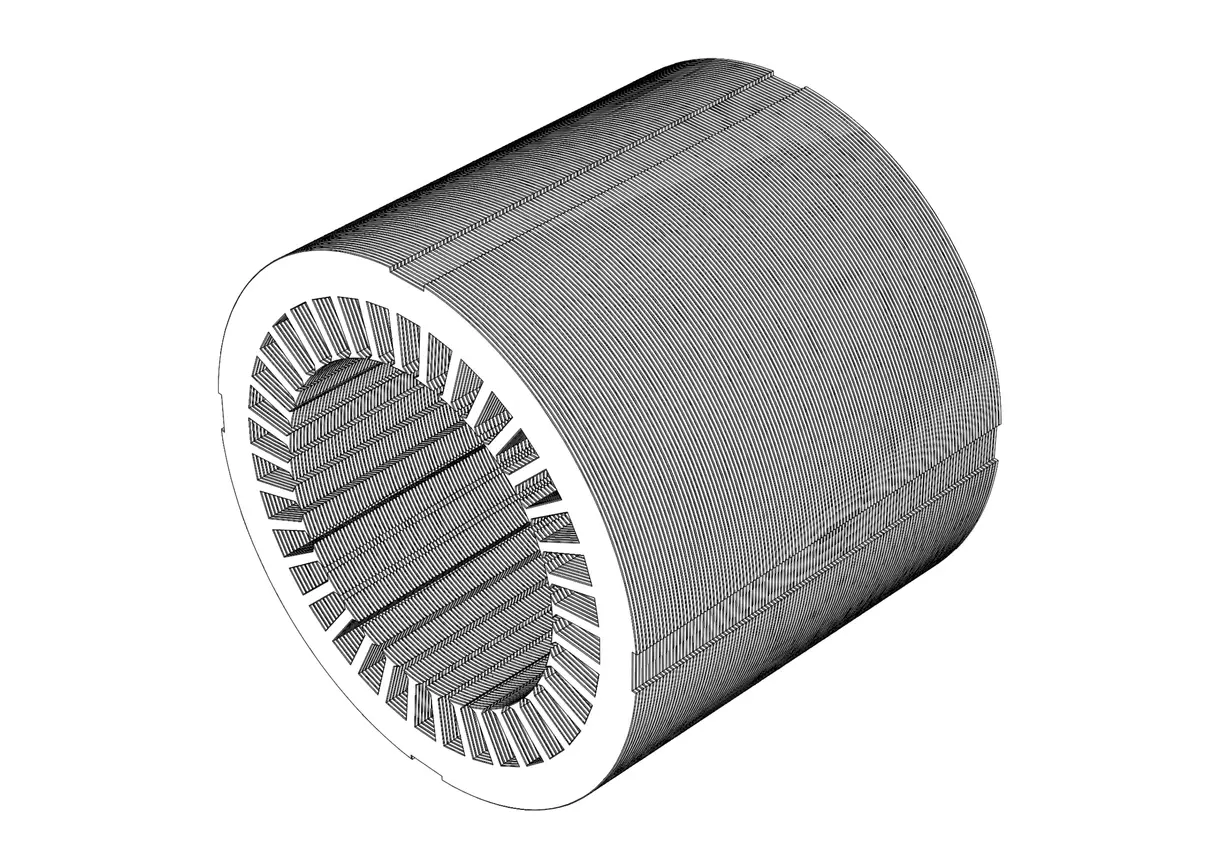

Stator bonding, also known as adhesive self bonding, represents a modern alternative gaining traction in high-performance applications. This process uses layers of adhesives on electrical steel to create a monolithic stator core while preserving the electrical isolation critical for minimizing eddy current losses. The method has evolved from experimental status to production implementation across multiple industries requiring superior electromagnetic performance.

A Head-to-Head Comparison: Bonding vs. Welding vs. Interlocking

The choice of assembly method directly impacts the magnetic circuit and structural integrity of the stator, affecting key performance indicators like efficiency and NVH (Noise, Vibration, and Harshness). Understanding these relationships requires examining each method’s impact on electromagnetic behavior.

Assembly Method Comparison Matrix

| Feature | Adhesive Bonding | Welding | Interlocking (Riveting) |

|---|---|---|---|

| Magnetic Performance | Excellent: No shorting between laminations | Poor: Welds create shorts, increasing loss | Good: Minimal impact on magnetic path |

| Mechanical Stability | Excellent: Forms a solid, homogenous unit | Good: Strong at weld points, but can warp | Fair: Can loosen under high vibration |

| Thermal Conductivity | Very Good: Adhesive fills gaps, aiding heat transfer | Fair: Tiny gaps remain between laminations | Poor: Air gaps trap heat |

| Acoustic Noise (NVH) | Excellent: Dampens vibration and noise | Fair: Can be a source of resonance | Fair to Poor: Prone to mechanical noise |

| Design Flexibility | Excellent: No need for interlocking features | Good: Can be applied to many shapes | Poor: Requires specific lamination geometry |

| Ideal Application | High-efficiency EV motors, servo motors, drones | Cost-sensitive industrial motors | Cost-sensitive performance applications |

The Engineering Benefits: A Deeper Dive

Reduced Eddy Current Losses for Higher Efficiency

Welding fundamentally compromises laminated construction by fusing the lamination edges, creating potential electrical shorts between layers. These unintended conductive pathways allow eddy currents to circulate in larger loops, generating resistive losses that convert electrical energy to waste heat. The magnitude of this eddy loss effect increases with frequency square, making it particularly problematic in high-speed or variable-frequency applications.

Bonded stator core assembly maintains the electrical insulation between every lamination, preserving the intended magnetic circuit design. The adhesive acts as both a structural bond and an electrical insulator, ensuring that eddy currents remain confined to individual laminations where their circulation paths are minimized.

This preservation of lamination isolation becomes critical in high-frequency motor applications. In a motor operating above 400 Hz, the losses from welding-induced shorts can reduce efficiency by several percentage points—a significant penalty in battery-powered applications like electric vehicles where every watt counts toward range and performance.

Superior Thermal Management

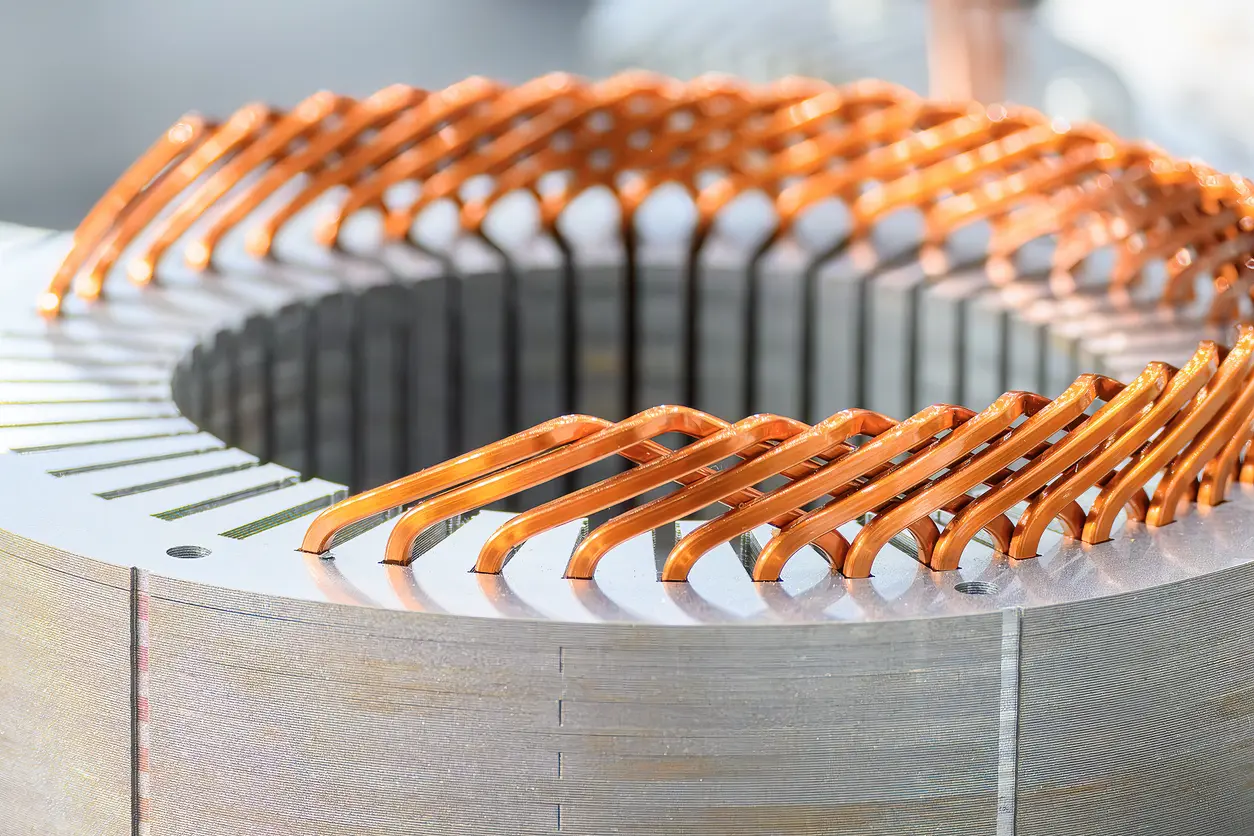

The adhesive used in bonding flows between the laminations during assembly, filling the microscopic air gaps that are inherent in welded or interlocked stacks. Air, with its thermal conductivity of approximately 0.026 W/m·K at room temperature, creates thermal barriers that impede heat transfer from the motor windings to the stator housing.

Modern bonding adhesives typically exhibit thermal conductivities ranging from 0.5 to 2.0 W/m·K—significantly higher than air. By replacing these small air gaps with adhesive, the overall thermal conductivity of the stator stack improves substantially, creating more efficient heat transfer paths.

This enhanced thermal management delivers multiple benefits. A cooler-running motor experiences less thermal stress on insulation materials, extending operational life. Additionally, improved cooling allows higher power densities and continuous duty ratings without overheating concerns.

Enhanced Mechanical Integrity and Lower NVH

A bonded stator core behaves as a single, solid piece of bonded metal rather than a stack of loose individual laminations. This monolithic structure exhibits exceptional rigidity and resistance to the vibrational and torsional forces experienced during motor operation, particularly during startup transients and load changes.

This structural rigidity significantly reduces lamination rattling and humming—common sources of acoustic noise in electric motors caused by harmonics. Individual laminations in welded or interlocked stacks can develop microscopic movement under electromagnetic forces, creating mechanical noise that transmits through the motor structure to the surrounding environment.

The acoustic benefits prove especially valuable in premium applications like electric vehicles and medical devices, where noise levels directly impact user acceptance and regulatory compliance.

Quantifying the Difference: Performance Data

Illustrative Performance Comparison (Identical Motor Design)

| Performance Metric | Welded Stator Core | Bonded Stator Core | Improvement |

|---|---|---|---|

| Core Loss @ 1.5T, 400Hz | 120 W | 95 W | -20.8% |

| Peak Operating Temp. | 135°C | 122°C | -9.6% |

| Acoustic Noise @ 6000 RPM | 65 dB | 58 dB | -7 dB |

| Stack Dimensional Stability | Good (potential for warp) | Excellent (uniform) | Enhanced |

These performance improvements compound in real-world applications. The 20.8% reduction in core losses directly translates to higher motor efficiency, while the 13°C temperature reduction enables higher power density operation. The 7 dB acoustic improvement represents a significant reduction in perceived noise levels. *Results may vary depending on material selection, geometry design, and other stator assembly aspects such as copper winding.

A Manufacturing Engineer’s Personal Insight

“From an assembly perspective, the biggest surprise with bonding was consistency. With welding, you’re always chasing variables—weld penetration, heat settings, wire feed—that can cause slight warping. A warped stator is a nightmare for inserting windings or press-fitting into a housing. Bonding is a far more controllable, repeatable process. We utilize the pre-applied eSteel rolls, stamping the stack, and cure it. The resulting stacks are dimensionally excellent, which has dramatically reduced downstream assembly issues.”

This manufacturing perspective highlights an often-overlooked advantage of bonded stator core assembly: process consistency. The elimination of thermal distortion from welding heat input creates more predictable dimensional outcomes, reducing quality control rejects and downstream assembly problems.

Frequently Asked Questions

Is the adhesive in a bonded stator strong enough for high-torque applications?

Modern structural adhesives (self-bonding) used for stator bonding are engineered to have extremely high shear strength and thermal stability, often exceeding the operational requirements. These adhesives are designed to maintain their properties throughout the entire motor lifespan without degrading under normal operating conditions (e.g. temperature limitation around 250 degrees celsius).

Does stator bonding cost more than welding?

The upfront process cost can be slightly higher due to the cost of the adhesive electrical steel sheets. However, this is often offset by the improved motor efficiency (lower core loss) and the reduction in rejected parts due to weld-induced warping, leading to a lower total cost of ownership.

Can you bond any type of electrical steel?

The bonding process is compatible with all grades of electrical steel and their associated insulation coatings (like C-5). The key is ensuring the surface is clean and properly prepared before the adhesive is applied or go for the electrical steel sheets that come with the pre-applied adhesive to guarantee a strong, reliable bond.

A Strategic Choice for Modern Engineering

Engineers are choosing bonded stator cores not for a single benefit, but for a compounding set of advantages—higher efficiency, better cooling, and quieter operation. These improvements align with industry trends toward higher performance density, stricter efficiency regulations, and enhanced user experience expectations.

While TIG and laser welding remains viable for many cost-sensitive applications, bonding has become the preferred solution when performance and reliability cannot be compromised. The method’s ability to preserve the fundamental principles of laminated construction while enhancing mechanical integrity makes it particularly valuable in demanding applications.

The quantifiable performance improvements—reduced core losses, lower operating temperatures, and decreased acoustic noise—justify the adoption of bonded stator core assembly in applications where these parameters directly impact system success.

Considering stator bonding for your next project? Contact our engineering team to evaluate whether this assembly method aligns with your application requirements and performance objectives.