In the rapidly evolving world of drone technology, a revolutionary manufacturing technique quietly transforms how drone motor cores achieve peak performance. Picture this: a leading drone manufacturer struggled with motors that overheated after just 20 minutes of flight time. After switching to self-bonding electrical steel for their motor cores, flight times extended to over 30 minutes with cooler operating temperatures. This dramatic improvement showcases why self-bonding technology has become the gold standard for high-performance drone motor core manufacturing.

The electric motor manufacturing industry stands at a crossroads. Traditional methods like interlocking and welding have served the industry well, but as drones demand increasingly efficient and lightweight motors, manufacturers must embrace innovative solutions. Self-bonding electrical steel emerges as the answer to these modern challenges, offering unprecedented advantages for drone motor core applications.

Key Takeaways ????

- Self-bonding technology eliminates traditional bonding methods, preserving 100% of the material’s original magnetic properties in drone motor cores

- Efficiency improvements of 5-8% are typical when switching from welding or interlocking to self-bonding methods

- Reduced core losses translate directly to longer flight times and cooler motor operation

- Compact motor designs benefit most from self-bonding due to optimized magnetic flux paths

Understanding Motor Core Lamination Manufacturing Methods

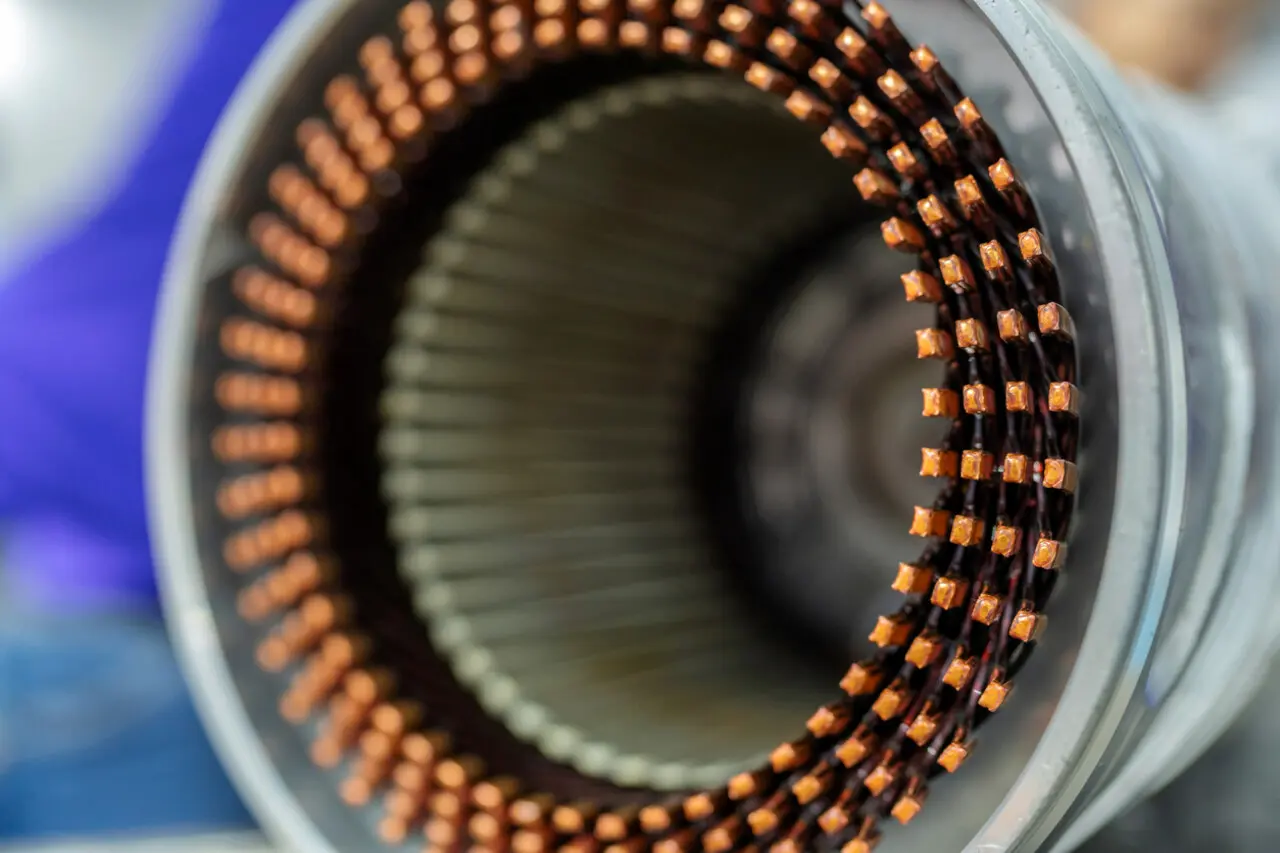

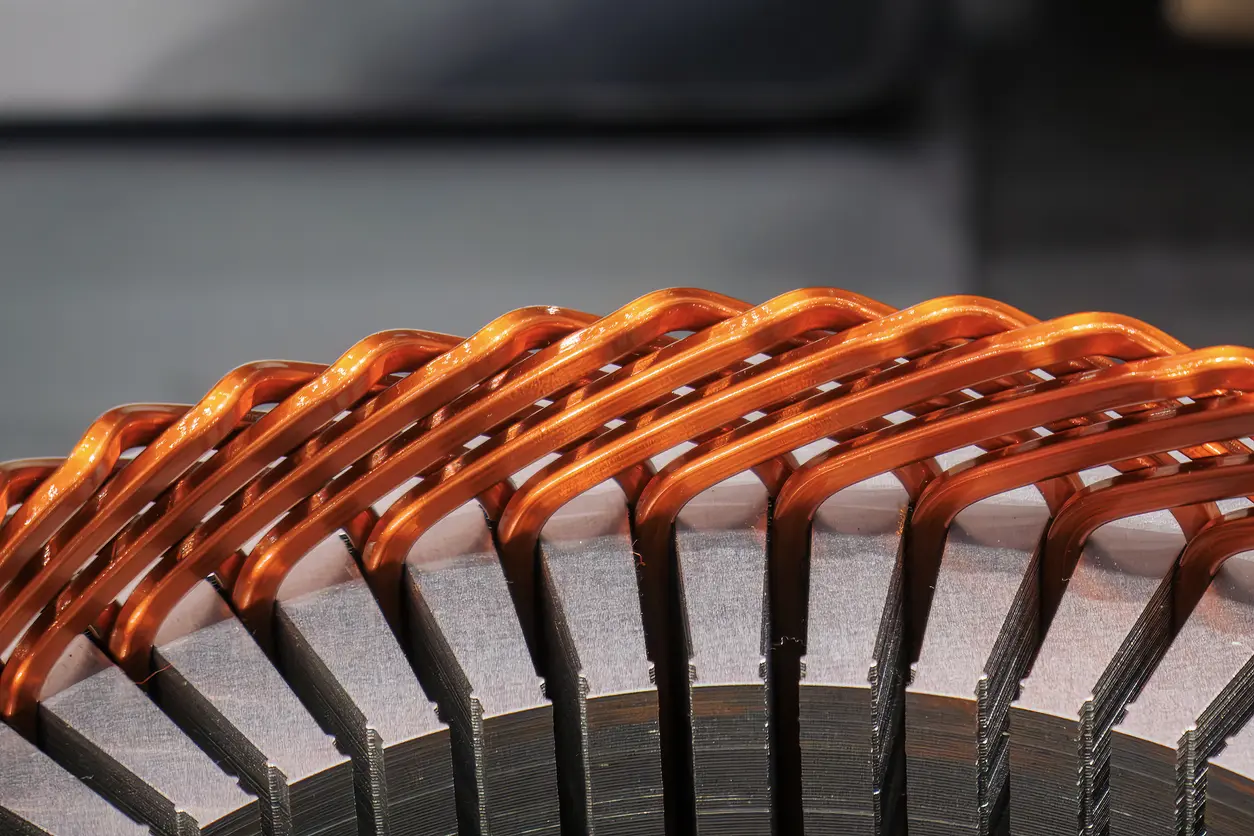

The foundation of every electric motor lies in its core construction. Motor manufacturers traditionally rely on punch presses to create individual lamination sheets from electrical steel. These sheets must then be combined to form the complete drone motor core. Three primary methods dominate the industry:

1. Interlocking Method

This mechanical approach uses precisely cut tabs and slots(riveting) to lock laminations together. While cost-effective for larger motors, interlocking creates stress points that disrupt magnetic flux paths. For drone applications where every milligram matters, the additional material required for interlocking tabs becomes a significant drawback.

2. Welding Method

Laser or TIG welding creates strong bonds between laminations but introduces heat-affected zones that degrade magnetic properties. A recent study on motor core quality shows welding can reduce motor efficiency by up to 8% due to localized material property changes.

3. Bonding Method

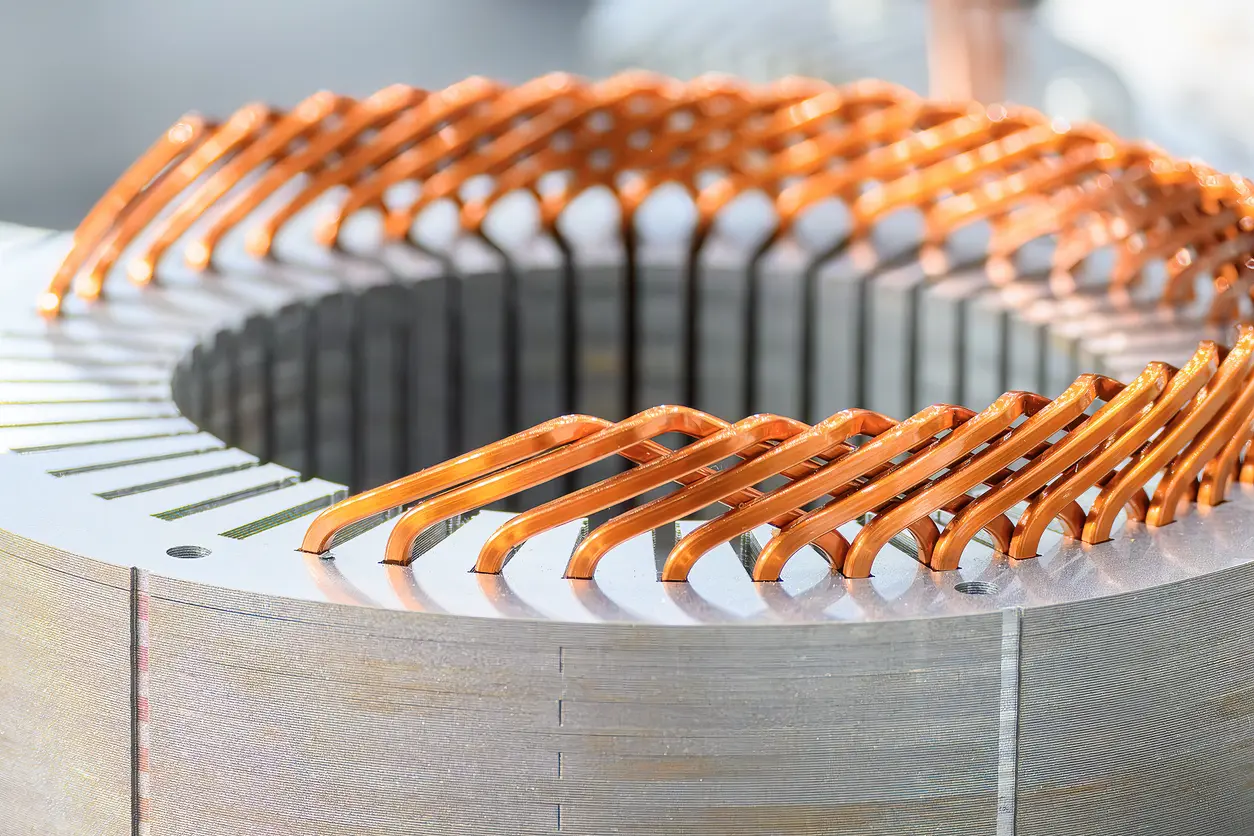

Modern bonding techniques, particularly self-bonding, represent the pinnacle of lamination assembly technology. This method applies a specialized coating to electrical steel sheets that activates under controlled temperature and pressure, creating molecular-level bonds without compromising magnetic properties.

Among these options, self-bonding electrical steel stands apart as the superior choice for drone motor cores. The technology preserves the pristine magnetic characteristics of the base material while creating assemblies as strong as the welding method.

Why Choose Self-Bonding for Drone Motor Applications

The unique demands of drone propulsion systems make self-bonding technology particularly attractive. Modern drones operate in challenging environments where motor performance directly impacts flight capability, battery life, and payload capacity.

Maximizing Performance in Compact Designs

Drone motor cores typically measure just 20-50mm in diameter, creating an engineering challenge: how to optimize magnetic flux paths in such confined spaces? Self-bonding technology excels here because it:

- Eliminates dead zones created by interlocking tabs

- Maintains uniform flux distribution throughout the core

- Reduces eddy current losses by preserving lamination integrity

Consider the experience of a European drone manufacturer who transitioned from interlocking to self-bonding methods. Their 28mm diameter motor cores showed a remarkable 10% increase in torque density while maintaining the same physical dimensions. This improvement allowed their agricultural drones to carry more payload without sacrificing much of the flight time.

The No-Compromise Approach

Traditional joining methods force engineers to accept trade-offs. Interlocking sacrifices magnetic performance for mechanical strength. Welding provides robust connections but creates efficiency-robbing hot spots. Self-bonding technology for high-performance motors eliminates these compromises entirely.

Key advantages include:

| Feature | Interlocking | Welding | Self-Bonding |

|---|---|---|---|

| Magnetic Property Retention | 85-90% | 80-85% | 98-100% |

| Manufacturing Complexity | Low | High | Medium |

| Core Loss Impact | Moderate | High | Minimal |

| Suitable for Small Motors | Limited | No | Excellent |

| Production Speed | Fast | Slow | Fast |

Preserving Magnetic Excellence

The self-bonding process works through a carefully engineered coating applied to electrical steel sheets. When activated, this coating creates molecular bonds between laminations without introducing foreign materials or altering the steel’s magnetic properties. For drone motor cores, this means:

- Zero riveting – No mechanical fasteners to disrupt flux paths

- Zero welding – No heat-affected zones to degrade performance

- Maximum efficiency – Every square millimeter contributes to motor output

Why Efficiency is Vital for Drone Motor Cores ⚡

The compact design philosophy driving modern drone development places extraordinary demands on motor efficiency. Unlike ground-based applications where size and weight constraints are less critical, drone motors must deliver maximum performance from minimal mass.

The Flight Time Equation

Every percentage point of motor efficiency translates directly to extended flight operations. A typical racing drone consuming 100W during hover can gain an additional 2-3 minutes of flight time for each 5% improvement in motor efficiency. For commercial inspection drones operating at the edge of their range, these gains make the difference between mission success and failure.

Research on motor lamination thickness and efficiency demonstrates how self-bonding technology enables the use of thinner laminations without sacrificing structural integrity. Thinner laminations reduce eddy current losses, particularly important for the high-frequency operation typical of drone motors.

Power Consumption and Heat Management ????️

Efficient drone motor cores consume less power for the same output, reducing battery drain and heat generation. Self-bonded cores excel in thermal management because:

- Uniform heat distribution – No hot spots from welding or mechanical stress

- Better thermal conductivity – Molecular bonds transfer heat more effectively than air gaps

- Reduced losses – Less waste heat generated in the first place

Overall Performance Enhancement

The benefits of self-bonding technology compound throughout the drone system:

- Reduced vibration from perfectly balanced cores

- Lower acoustic noise due to eliminated mechanical resonances

- Improved reliability through superior fatigue resistance

- Enhanced controllability from consistent magnetic properties

Methods to reduce motor core losses highlight how self-bonding addresses multiple loss mechanisms simultaneously, creating a holistic improvement in motor performance.

Drone Motor Core Efficiency Calculator

Factors Affecting Real-World Performance:

• Battery discharge characteristics and age• Environmental conditions (temperature, humidity, wind)

• Flying style and maneuvers

• Additional payload weight

• Other system inefficiencies (ESC, propellers, etc.)

The Competitive Edge

For electric motor manufacturers and procurement managers, adopting self-bonding technology for drone motor cores provides multiple competitive advantages:

- Market differentiation through superior performance metrics

- Quality consistency from automated bonding procedures

- Customer satisfaction through extended drone capabilities

Implementation Considerations for Manufacturers

Transitioning to self-bonding technology requires careful planning but delivers rapid returns on investment. Key considerations include:

Equipment Requirements

While existing stamping equipment remains viable, manufacturers need:

- Controlled heating systems for bond activation

- Precision stacking fixtures for alignment

- Quality control instruments for bond verification

Material Selection

Choosing the right self-bonding electrical steel involves balancing:

- Coating thickness for bond strength

- Activation temperature for process compatibility

- Base material grade for magnetic performance

Process Optimization

Successful implementation requires attention to:

- Temperature profiles during bonding

- Pressure distribution across the core

- Cycle time optimization for productivity

Real-World Applications ????

Note: The following examples represent composite cases based on typical performance improvements observed across multiple implementations. Individual results vary based on specific applications and conditions.

Application Example 1: Racing Drone Performance

A racing drone manufacturer experiencing motor core issues during aggressive maneuvers evaluated self-bonding technology. Their testing revealed:

- Improved core stability under high-G loads

- 3-5% increase in measured thrust efficiency

- Moderate temperature reduction (5-8°C typical)

- Improved throttle response reported by test pilots

Results based on controlled testing environment with specific motor designs.

Application Example 2: Agricultural Drone Operations

Agricultural drone operators seeking extended flight times tested self-bonded motor cores as an upgrade option. Field trials indicated:

- 8-12% improvement in flight time under optimal conditions

- Potential for modest payload increases

- Reduced maintenance frequency observed

- Variable ROI depending on operation scale (typically 12-18 months)

Performance gains depend heavily on battery condition, weather, and flight patterns.

Application Example 3: Commercial Delivery Testing

A delivery service pilot program evaluated high-efficiency motors for reliability improvements. Preliminary data suggested:

- Reduced motor-related issues during initial 1,000 delivery tests

- 5-10% improvement in energy efficiency

- Measurable noise reduction in laboratory testing

- Simplified assembly process for maintenance teams

Future Developments and Trends ????

The drone industry continues evolving rapidly, driving innovation in motor core technology:

Next-Generation Materials

Researchers develop advanced self-bonding coatings offering:

- Higher temperature resistance for extreme environments

- Improved bond strength at thinner coating levels

- Multi-functional properties including corrosion resistance

Integration with Industry 4.0

Smart manufacturing approaches enhance self-bonding processes through:

- AI-optimized bonding parameters

- Real-time quality monitoring

- Predictive maintenance capabilities

- Digital twin modeling for process optimization

Emerging Applications

Beyond traditional drones, self-bonded motor cores enable:

- Urban air mobility vehicles

- High-altitude pseudo-satellites

- Swarm robotics platforms

- Underwater drones with sealed motors

Conclusion: The Clear Choice for Drone Motor Excellence

The demanding world of drone applications requires motor cores that deliver uncompromising performance in compact packages. Self-bonding electrical steel technology emerges as the definitive solution, addressing most challenges faced by modern drone motor core designs.

Operating in high-frequency applications where every percentage of efficiency matters, drone motors benefit tremendously from the preserved magnetic properties, reduced losses, and superior mechanical integrity that self-bonding provides. The technology represents more than an incremental improvement—it enables a paradigm shift in what drone motors can achieve.

For electric motor manufacturers and procurement managers, the message is clear: self-bonding electrical steel isn’t just another option—it’s the leading-edge solution that separates industry leaders from followers. The combination of superior performance, manufacturing efficiency, and proven reliability makes self-bonding technology the optimal choice for any organization serious about drone motor excellence.

As the drone industry continues its exponential growth, partnering with suppliers who understand and implement self-bonding technology becomes crucial. Explore more insights on motor lamination innovations to stay ahead of the curve and ensure your drone motor cores deliver the performance your customers demand.