1. Introduction to AI Robot Electric Motors

1.1 Definitions and Core Concepts

AI Robot Electric Motors are motor systems specifically designed to achieve precise and diversified movements in robots. These motors provide the necessary torque and speed for robots to operate in complex and dynamic environments. With the rapid development of AI technology, AI robot Electric Motors have continuously improved in control accuracy, energy efficiency, and operational stability, gradually becoming a vital cornerstone for advancing the robotics industry.

1.2 Technical Requirements and Design Considerations

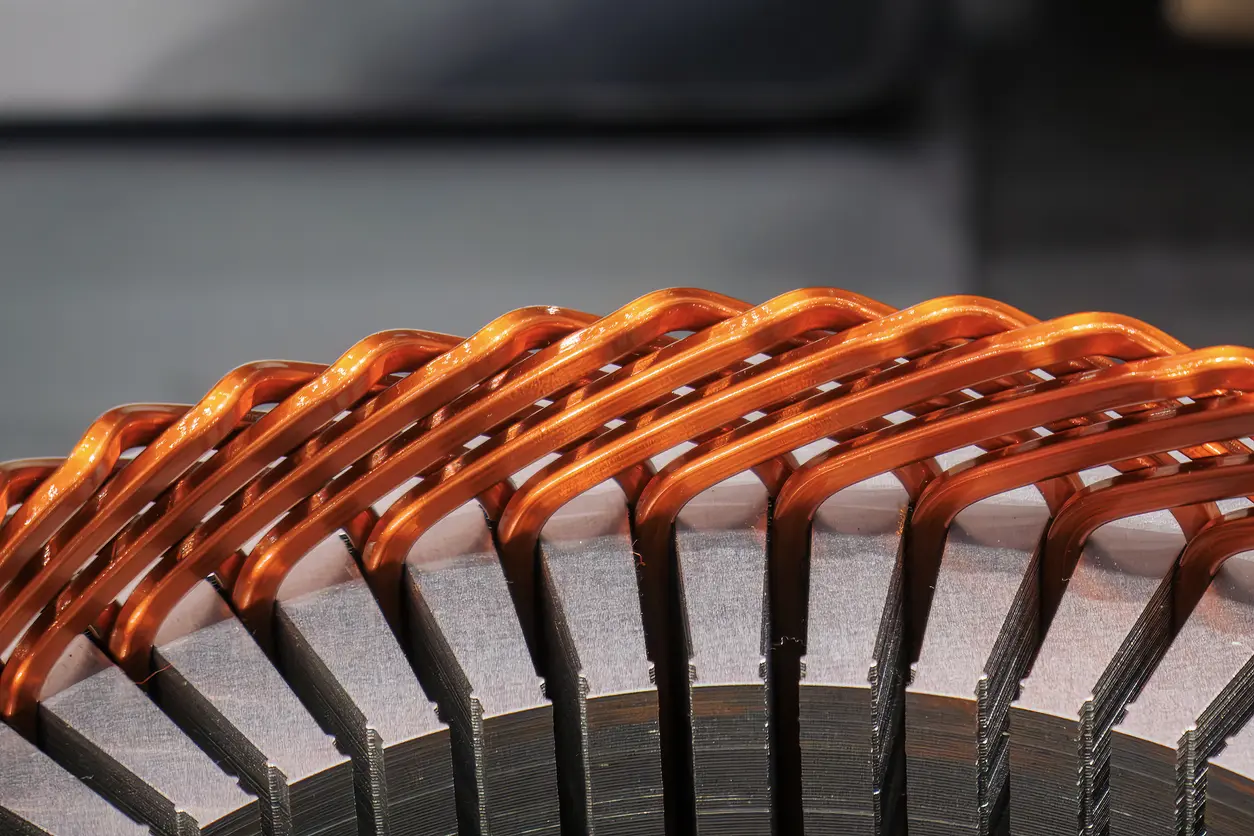

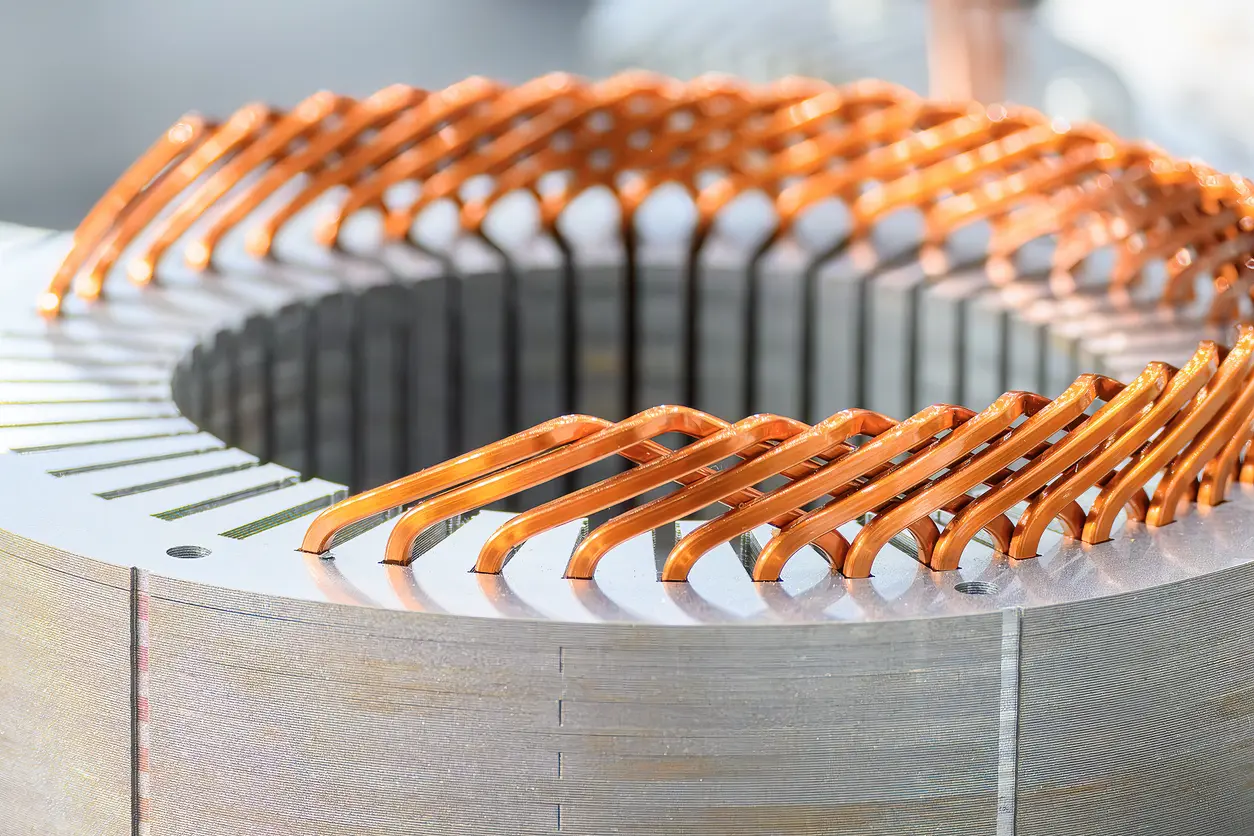

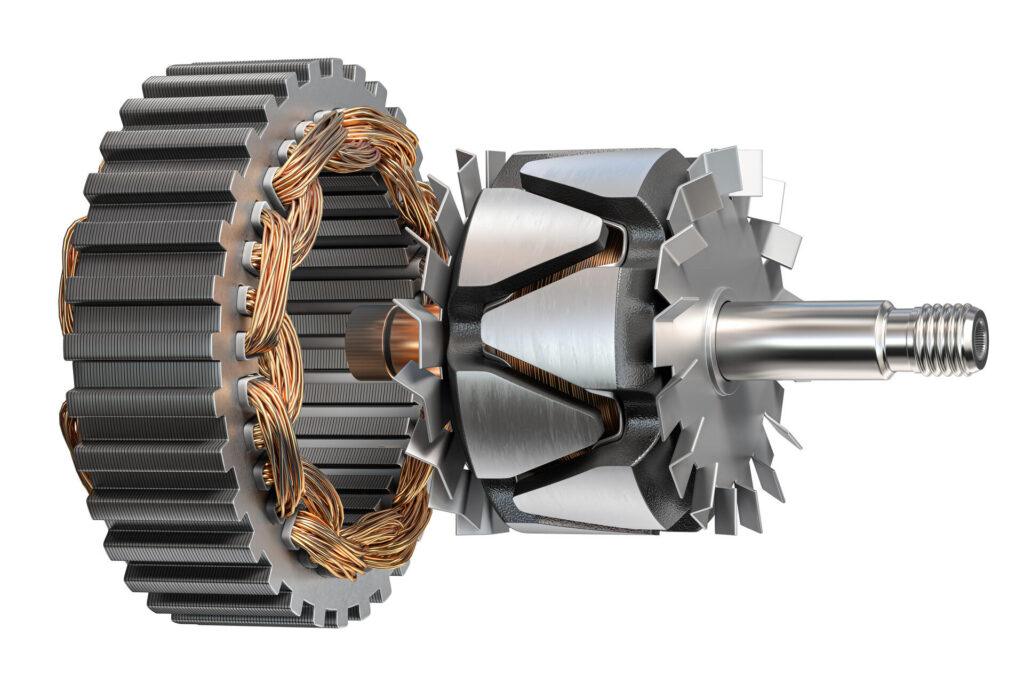

Selecting appropriate materials and structural designs is key to ensuring the performance of AI Robot Electric Motors. Motors must be able to maintain low vibration and low noise levels even at high speeds or during fine positioning, while also addressing heat dissipation and structural integrity. Common critical components of a motor include the stator, rotor, and the motor core; the material and manufacturing quality of these components affect the motor’s efficiency during startup, acceleration, and continuous operation. As robots are used in a wide range of applications—such as industrial production lines, medical devices, and even home services—the differing requirements of each scenario necessitate that AI Robot Electric Motors meet diverse needs and constraints.

1.3 Industry Trends and Future Development

With the rapid growth of the robotics industry, the demand for AI Robot Electric Motors is steadily on the rise. These motors require ongoing optimization in energy consumption and cost-effectiveness and are also evolving toward lighter weight and higher power density. Although there is no single solution that can perfectly meet all application needs, continuous technological research and material innovations have enabled many manufacturers to develop highly accurate and durable AI Robot Electric Motors tailored to specific industry requirements. For businesses, choosing the right motor design not only enhances product performance but also reduces long-term operational risks and maintenance costs. As automation and AI continue to gain traction, the importance of AI Robot Electric Motors is bound to keep growing.

2. Overview of Silicon Steel in Electric Motors

2.1 Material Composition and Magnetic Properties

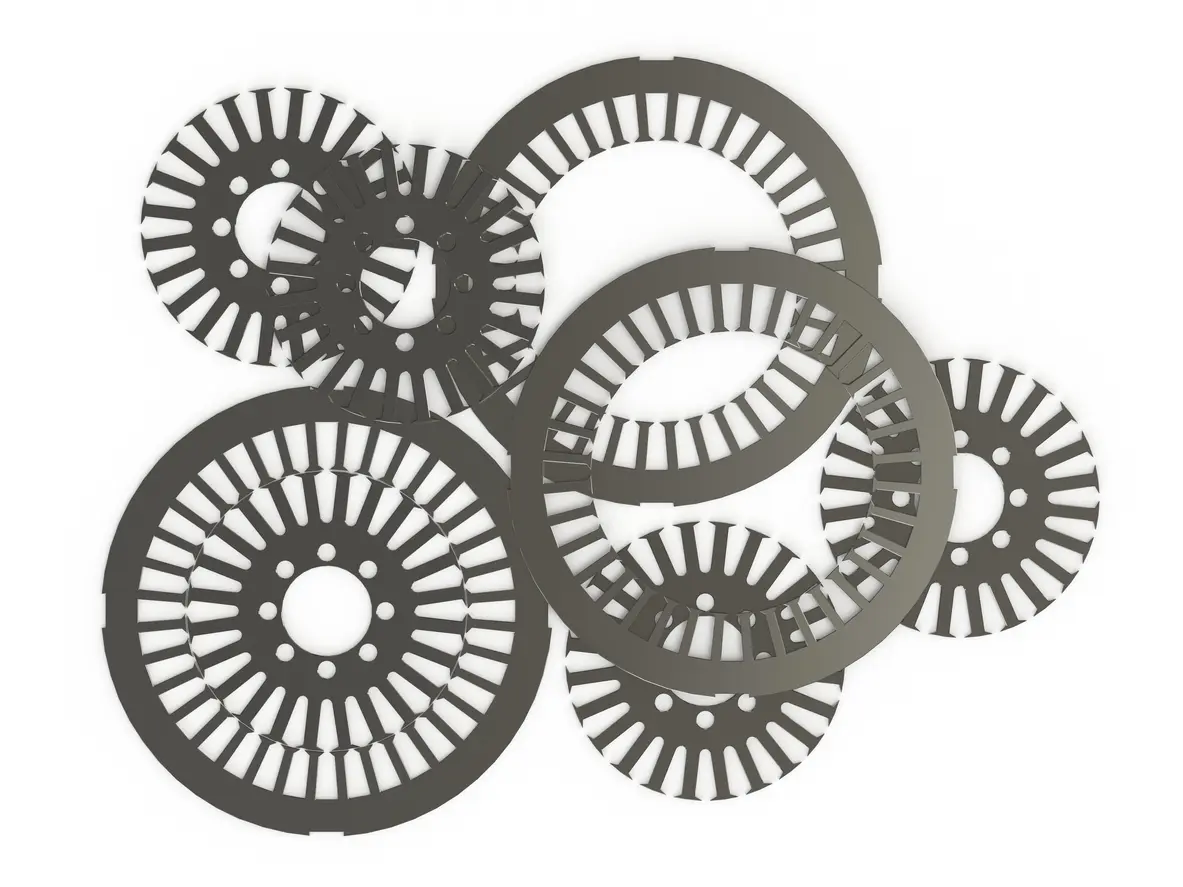

Silicon steel is a special alloy steel containing a certain proportion of silicon, known for its favorable electrical and magnetic characteristics. It is commonly used in a wide range of electric motors. As a key material in motor design, silicon steel effectively reduces eddy current and hysteresis losses, thereby improving a motor’s energy conversion efficiency when powered. Meanwhile, the structure of silicon steel helps stabilize the motor’s magnetic circuit, allowing it to maintain better power output under various speeds and load conditions. With the rapid development of AI Robot Electric Motors, selecting silicon steel sheets of appropriate grade and thickness can further help these intelligent robots achieve stable and precise motion control.

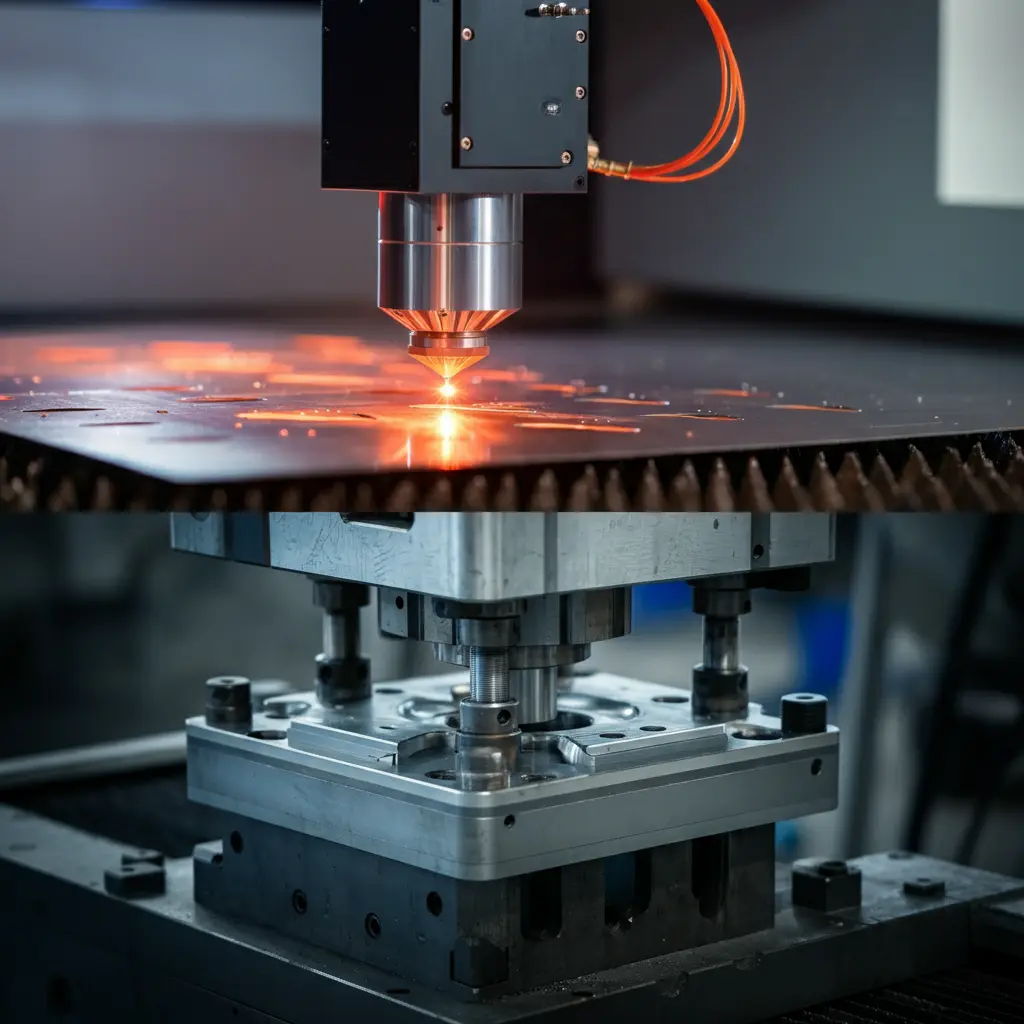

2.2 Manufacturing Process and Quality Control

During the production of silicon steel sheets, methods such as stamping or laser cutting are often used for shaping, followed by a lamination process to combine multiple layers of silicon steel into the desired motor core. To reduce interlayer losses and maintain stable magnetic flux, careful attention must be paid to lamination quality and surface treatment throughout manufacturing. Some manufacturers also apply insulating coatings on the silicon steel sheets to prevent short circuits between layers and to enhance the motor’s operating efficiency. Because these details have a direct impact on the final product’s performance and durability—especially in high-precision, high-operating-hour environments—quality control becomes extremely important, and companies typically strive for strict oversight.

2.3 Future Prospects in AI Robot Electric Motors

As artificial intelligence and automation demands continue to grow, the design of AI Robot Electric Motors is increasingly moving toward high performance and lighter weight. In this trend, silicon steel, with its excellent magnetic properties and durability, has become a favored material among motor designers. While other metallic alloys or composite materials remain available, silicon steel offers a relatively balanced solution in terms of magnetic permeability, manufacturability, and cost. Of course, any material choice should be based on the actual application environment and technical requirements, but given current developments, silicon steel still holds considerable potential in AI Robot Electric Motors.

3. Benefit 1: Enhanced Energy Efficiency

3.1 Major Sources of Energy Loss

During the operation of AI Robot Electric Motors, energy losses often originate from various factors, including eddy currents, hysteresis losses, and the heat generated by high-speed operation. If these pathways for energy loss are thoroughly considered in the motor’s design phase and appropriate core materials and structures are chosen, it can significantly reduce energy losses during operation. Especially for AI Robot Electric Motors that require extended operating hours or high-precision control, continuously optimizing the magnetic properties and heat dissipation of the motor core can lead to remarkable performance gains.

3.2 Key Factors for Improving Efficiency

Achieving a high-efficiency motor design typically depends on careful material selection and manufacturing processes—such as using the right grade of silicon steel sheets and minimizing interlayer losses during lamination. By doing so, AI Robot Electric Motors can reduce unnecessary energy consumption during startup and speed adjustments, ensuring stable operations and sustained power output for the robot. Additionally, maintaining an optimal operating temperature further lowers the wear rate of individual components, helping to reduce future maintenance and replacement costs. While not every application scenario can achieve the same efficiency level, continuous refinement in design and testing can still yield a more balanced performance.

3.3 Practical Applications and Potential Impact

From a practical standpoint, boosting the energy efficiency of AI Robot Electric Motors not only cuts down on power consumption but also indirectly extends a robot’s operating time or working capacity. This advantage holds considerable value in fields such as industrial automation, logistics, healthcare, and even domestic robotics. Although not all efficiency improvements can meet cost and production deadlines simultaneously, most manufacturers remain dedicated to researching new materials and innovations in motor design. As a result, the energy efficiency of AI Robot Electric Motors can gradually align with market needs—benefiting both business profitability and long-term environmental goals.

4. Benefit 2: Superior Performance in High-Frequency Applications

4.1 Demands and Challenges of High-Frequency Operations

In many scenarios that require rapid response and precise control, electric motors are often expected to run at high frequencies. AI Robot Electric Motors that can maintain stable performance at high speeds not only enhance a robot’s dynamic responsiveness but also enable it to complete complex tasks in a shorter time. However, high-frequency operations typically involve more significant electromagnetic and thermal loads. Without proper attention, these loads can lead to increased vibration or reduced efficiency. To prevent such issues, careful consideration must be given during the design phase to material properties, internal structures, and cooling methods to ensure that the motor can deliver both power output and stability under high-speed conditions.

4.2 Overcoming Induction and Heat Generation Challenges

When running at high frequency, the rapid changes in current increase the induction effects within AI Robot Electric Motors. On one hand, if the core materials cannot effectively suppress eddy currents and hysteresis losses, energy consumption can rise significantly at higher frequencies. On the other hand, additional heat generated during operation may increase the wear and failure risks of internal components. To address these issues, the industry often selects premium silicon steel sheets or other alloy materials to enhance magnetic efficiency and reduce heat buildup. Furthermore, designing effective cooling channels within the motor structure or employing forced cooling systems when necessary can help achieve more stable output in high-frequency applications.

4.3 Practical Applications and Long-Term Impact

Once a motor can operate efficiently at high frequency, AI Robot Electric Motors will stand out more readily in industrial automation, rapid production-line changes, and other complex tasks. For example, in electronic component assembly or precision testing, high-frequency motors can shorten processing times and reduce the likelihood of errors. While more resources and repeated adjustments are required during the design and testing stages—especially given varying application scenarios—maintaining stable AI Robot Electric Motors in high-frequency applications can offer notable efficiency gains and cost benefits over the long run. Consequently, overall system reliability and productivity may see significant improvements.

5. Benefit 3: Compact and Lightweight Motor Design

5.1 Miniaturization and Space Utilization

When developing AI Robot Electric Motors, a compact and lightweight design often brings multiple benefits. First, smaller motors make it easier for robotic systems to accommodate additional sensors or actuators within limited space, thereby enhancing overall flexibility. This is especially advantageous in applications requiring delicate operations or high mobility—such as medical assistance robots or precision assembly lines—where a smaller motor can reduce the risk of collisions or interference, thus improving operational safety. At the same time, choosing high-permeability, relatively thin silicon steel sheets can help maintain sufficient torque output and reliability while reducing the motor’s physical footprint.

5.2 Reduced Weight and Improved Efficiency

Beyond reduced size, miniaturized designs typically come with lower weight. AI Robot Electric Motors that are both lightweight and robust can significantly cut energy consumption and extend operating time for mobile or wearable robots. Additionally, a lighter design lowers the load requirement, meaning the motor itself requires less force when accelerating or changing direction. Collectively, these factors enhance the robot’s agility and allow computing resources to be more efficiently allocated to control and sensing, further optimizing overall system performance.

5.3 Long-Term Benefits and Future Potential

Achieving truly lightweight, high-efficiency motors often demands iterative design and testing, but many manufacturers and research institutions continue to invest in this area, aiming to lay a stronger foundation for the future of AI Robot Electric Motors. By introducing new manufacturing processes or composite materials, these motors can not only shrink in size but also maintain or even increase output power to a certain degree. The ultimate goal is to help robotic devices meet operational demands while also providing easy maintenance and reduced energy costs. Although this design philosophy may not replace all existing solutions in the short term, for applications that require high standards for space and energy, compact and efficient AI Robot Electric Motors hold significant promise for the future.

6. Benefit 4: Reliability and Longevity

6.1 Stable Operation and Reduced Failure Risk

In many automated and service-oriented applications, the reliability of AI Robot Electric Motors has a direct impact on a robot’s performance and overall service life. When an electric motor can consistently operate under various loads and environmental conditions, it lowers the likelihood of failure, helping to prevent unexpected downtime as well as reduce repair and replacement costs. To achieve this high level of stability, motor designs often use durable materials and adopt rigorous manufacturing processes. For instance, the quality of silicon steel sheets in the lamination process, the uniformity of insulating layers, and the precision of the rotor–stator gap all affect a motor’s reliability. As long as these details meet the expected standards, AI Robot Electric Motors can typically deliver stable output over an extended period.

6.2 Design Factors for Prolonged Service Life

To give AI Robot Electric Motors a longer operational lifespan, material strength and structural design are essential considerations, but effective heat dissipation is just as crucial. If the heat generated by continuous motor operation cannot be promptly discharged, it accelerates internal component aging and leads to potential failures. As a result, some high-end motors incorporate enhanced heat dissipation mechanisms within the motor housing or in internal channels. Others work in conjunction with control systems to adjust speed or duty cycle during peak load periods.

Another key factor influencing motor life is vibration and noise management. Reducing internal resonance and unnecessary vibration during the design and assembly phases can mitigate wear and fatigue on various parts. Although these preventative measures may add to initial development costs, they often yield significant savings in maintenance and repairs over the long term—particularly for systems requiring stable and reliable performance over extended operation.

6.3 Overall Benefits and Future Outlook

When AI Robot Electric Motors offer both high reliability and durability, users can focus more on refining robotic functions and coordinating production lines without worrying that motor failures will cause project delays or soaring costs. As technologies advance and materials continue to improve, more motor designs will likely evolve to further enhance stability and longevity. For companies and research institutions, having a robust set of AI Robot Electric Motors that can stand the test of time is often the foundation for automating complex tasks and boosting overall system value.

7. Benefit 5: Environmental Advantages

7.1 Recyclability of Silicon Steel

Choosing the right materials is an essential part of developing AI Robot Electric Motors, particularly in an era that emphasizes environmental awareness and sustainability. Motor cores made primarily of silicon steel offer good recyclability, making both production and post-use handling more eco-friendly. Compared to some composite materials, silicon steel requires relatively lower energy consumption for recycling and reuse, thereby significantly reducing waste. While many manufacturers still weigh trade-offs between material costs and performance, being able to ensure motor efficiency while also supporting recyclability often proves to be a viable long-term strategy for cost reduction and efficiency gains. With more stringent production management and quality inspection processes in place, these electric motors may still maintain a certain level of energy efficiency and reliability after being recycled or refurbished.

7.2 Supporting Sustainable Robotics

Beyond having inherently recyclable materials, AI Robot Electric Motors that can reduce energy consumption and emissions during operation also provide positive environmental benefits. Many robotic applications run for long periods of time—like industrial automation or logistics and transportation systems—so when motor efficiency improves consistently, users can save on electricity costs and lessen environmental impact. Additionally, by employing advanced control algorithms and sensing technologies, these electric motors can meet power requirements while minimizing unnecessary idling or heat loss.

Looking ahead, sustainable robotics not only depends on advancements in AI technology but also on reliable, energy-efficient, and recyclable electric motors as hardware support. Although today’s AI Robot Electric Motors continue to evolve, there is no single solution that can completely replace all use cases. Nevertheless, ongoing research and industry collaboration may gradually popularize motors that balance eco-friendliness and performance. For companies and institutions committed to green tech and carbon reduction, choosing electric motors that lower energy consumption and promote a circular economy is undoubtedly a key step toward achieving sustainability goals.

8. Applications and Real-World Examples

8.1 The Use of AI Robot Electric Motors Across Different Industries

AI Robot Electric Motors are widely employed in virtually every sector that requires automation. For instance, in industrial production lines, robots equipped with highly precise sensors and image recognition systems can perform assembly and inspection tasks at exceptional speed and accuracy. In the logistics industry, smart warehouse robots rely on the stable torque and low energy consumption of AI Robot Electric Motors to handle sorting, transporting, and stacking of goods. Additionally, medical service robots and collaborative robots have become increasingly prevalent; with adjustable speeds and low-noise operations, these motors enable robots to safely function in complex clinical or domestic environments, providing patient care and everyday assistance.

8.2 Real-World Cases and Success Stories

In practical applications, some advanced manufacturers have extensively incorporated AI Robot Electric Motors into their production processes. For example, automotive parts suppliers use motors with high torque and fast control capabilities, enabling robots to achieve more rapid and accurate welding and assembly—greatly boosting productivity and reducing labor costs. In the semiconductor and electronics assembly sectors, where high standards of cleanliness and operational precision are required, AI Robot Electric Motors demonstrate advantages in thermal stability and continuous long-hour operations, successfully supporting various testing and assembly tasks in cleanroom settings.

It is worth noting that although most success stories highlight the motors’ impressive performance and reliability, maintenance and troubleshooting remain critical considerations in actual usage. By selecting the right motor specifications from the outset and incorporating effective monitoring systems and maintenance strategies later on, AI Robot Electric Motors can deliver long-lasting operation and substantial economic benefits over time. Whether in advanced manufacturing, logistics, healthcare, or service-oriented robotics, there is still significant room for optimization and innovation in electric motors—indicating that this field is likely to continue evolving and bring about further breakthroughs in the future.

9. Conclusion: Why Silicon Steel Matters for AI Robots

9.1 Overall Benefits and Key Role

When considering the multiple requirements of high efficiency, stability, and eco-friendliness, silicon steel has become a critical material in the development and manufacturing of AI Robot Electric Motors. By delivering outstanding magnetic properties and resistance to eddy currents, silicon steel helps reduce energy losses while providing stable output performance. For robots that require continuous long-hour operation or complex motion control, this material advantage significantly minimizes heat buildup and vibration risk, not only boosting operational efficiency but also extending the overall service life of the equipment. Although other alloys or composite materials are available for assessment, silicon steel still maintains a noteworthy balance in terms of magnetic permeability, manufacturability, and cost.

9.2 Future Development with AI Robot Electric Motors

Because AI Robot Electric Motors continue to demonstrate potential in diverse fields—ranging from industrial automation and medical services to consumer products—developing motors that are more efficient, lighter, and more reliable has become an inevitable goal. In this process, the role of silicon steel is expected to become even more prominent: whether it’s fine-tuning electromagnetic properties to meet high-speed operational demands or optimizing motor structures through layered lamination to reduce energy losses and noise, all such technological upgrades rely on the stable supply and research of silicon steel. Although no single material can solve every design challenge, in the face of rapid growth in AI and robotics technologies, silicon steel remains highly valuable within the motor domain.

9.3 Careful Selection and Ongoing Optimization

It’s important to note that incorporating silicon steel does not singlehandedly resolve all motor development and application issues. Factors such as size, weight, cost, and compatibility with other components may become crucial variables to consider during the design phase. Moreover, to ensure optimal performance in AI Robot Electric Motors, companies and research institutes still need to conduct experimental testing and continual refinements to fully tap into silicon steel’s potential and improve the system as a whole. Only by keeping an open mind toward various technological paths and by deepening our understanding of key materials like silicon steel can we enable robots to operate more reliably in complex environments and lay a solid foundation for future innovations.

External link: https://www.tandfonline.com/doi/abs/10.1080/02670836.2017.1295519

Internal link: Comparing Electric Motor Types for Industrial Robots: Which Is Right for You?