1.The Basics of Electric Drone Endurance

1.1 What is Drone Endurance?

Drone endurance refers to the amount of time or distance a drone can continuously fly on a single charge or refueling. This metric is crucial for evaluating a drone’s performance, as it directly impacts the effectiveness and efficiency of its tasks. Endurance is typically measured in minutes or hours and is influenced by several factors, including battery capacity, drone design, and environmental conditions.

When measuring endurance, standardized test environments and conditions are essential. For instance, flying in windless open spaces, using stable flight modes, and maintaining standard payloads help ensure comparable test results. However, in actual operations, factors such as wind speed, temperature, terrain, and piloting methods can cause the endurance to vary from test results.

1.2 Why is Drone Endurance Important?

Endurance is a core performance indicator for drones and holds significant importance across various applications. In commercial use cases like surveying, agricultural monitoring, and logistics delivery, longer endurance allows drones to cover larger areas and perform extended missions, thereby increasing efficiency and reducing operational costs.

For example, in the surveying industry, drones need to fly for extended periods to complete large-scale terrain scans. Improved endurance reduces the need for frequent battery swaps or return-to-base charging, ensuring continuous and complete data collection. In agriculture, drones are used to monitor crop health. Longer endurance enables a single flight to cover more farmland, providing comprehensive data support.

Furthermore, endurance directly impacts drone safety. Adequate flight time ensures drones can safely return after completing their tasks, preventing crashes or loss due to depleted battery power.

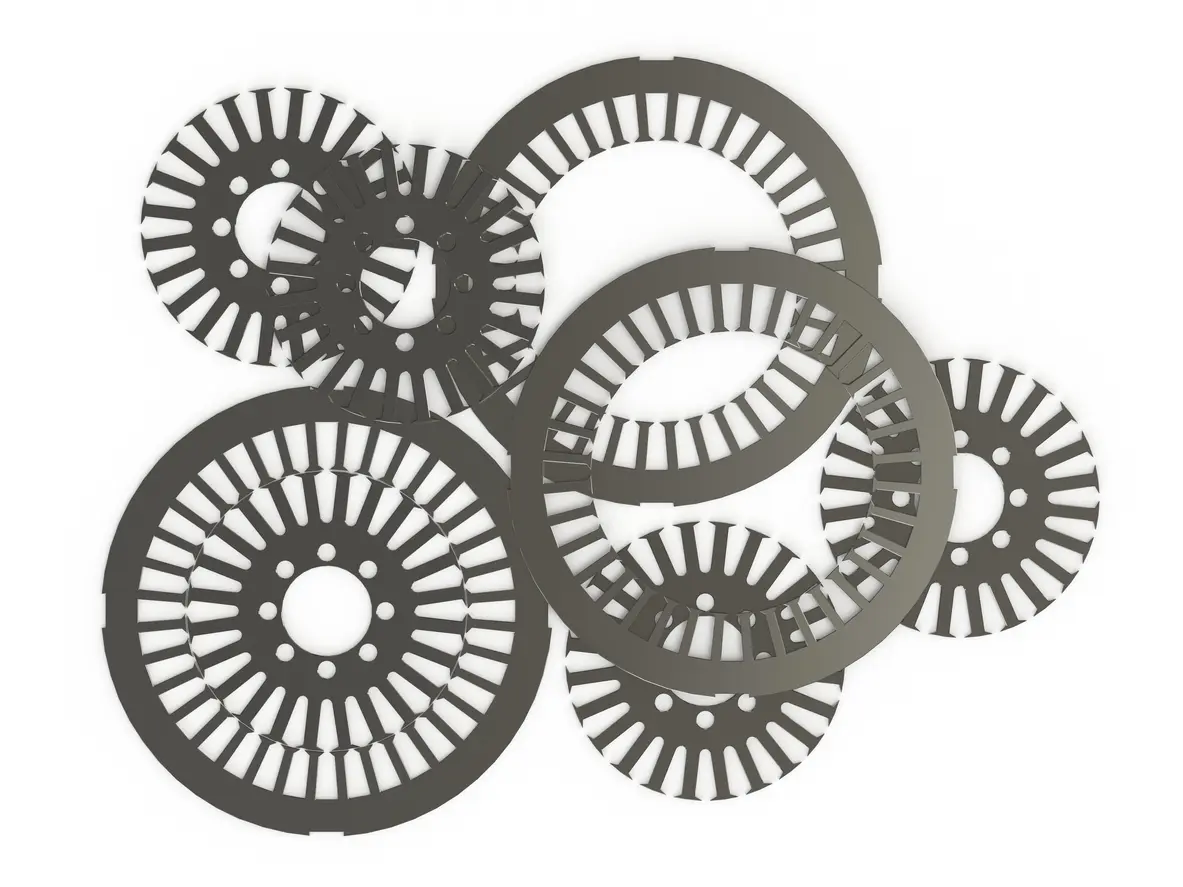

It is worth noting that a drone’s endurance is not solely determined by battery capacity. Factors such as body design, material selection, power system efficiency, and environmental conditions also impact endurance. For example, using “bonded lamination stacks” technology can enhance motor efficiency, thereby extending flight time. Therefore, when designing and selecting drones, various factors need to be considered comprehensively to ensure that the endurance meets the specific application requirements.

In summary, endurance is a critical parameter in drone performance evaluation, directly influencing its range of applications and efficiency. Understanding and optimizing endurance helps improve drone effectiveness across different industries and meet diverse operational needs.

2. Factors Affecting Electric Drone Endurance

2.1 Battery Capacity and Technology

The battery is the core component that determines a drone’s endurance. Generally, the higher the battery capacity, the longer the drone’s flight time. Battery capacity is measured in milliampere-hours (mAh), representing the amount of charge a battery can store. In addition to capacity, voltage (V) and discharge rate (C-rating) also impact the battery’s performance and the drone’s endurance.

Currently, the most common types of electric drone batteries are Lithium Polymer (LiPo) batteries and Lithium-Ion (Li-ion) batteries:

- LiPo Batteries: Known for their high energy density and discharge capacity, LiPo batteries are ideal for drones requiring high output power.

- Li-ion Batteries: While they have a lower discharge capacity compared to LiPo batteries, they have a longer lifespan, making them suitable for tasks requiring continuous discharge over extended periods.

Selecting the appropriate battery technology and capacity based on mission requirements can effectively improve drone endurance. Additionally, proper battery maintenance — such as avoiding overcharging and over-discharging, and routinely checking battery health — can extend battery life and maintain consistent endurance.

2.2 Drone Weight and Design

A drone’s weight and design significantly affect its endurance. The drone’s total weight includes the battery, camera, sensors, and other payloads. The heavier the drone, the higher the energy consumption, resulting in shorter endurance. Therefore, using lightweight materials is a crucial strategy for improving endurance.

Common lightweight materials include:

- Carbon Fiber: Lightweight and strong, ideal for drone arms and frames.

- Magnesium Alloy: Offers good structural strength and weight reduction, commonly used in high-performance drones.

In addition to material selection, aerodynamic design is also essential. Reducing air resistance lowers energy consumption during flight, thereby improving endurance. For example, a streamlined body design can effectively reduce drag, making the drone more energy-efficient during flight.

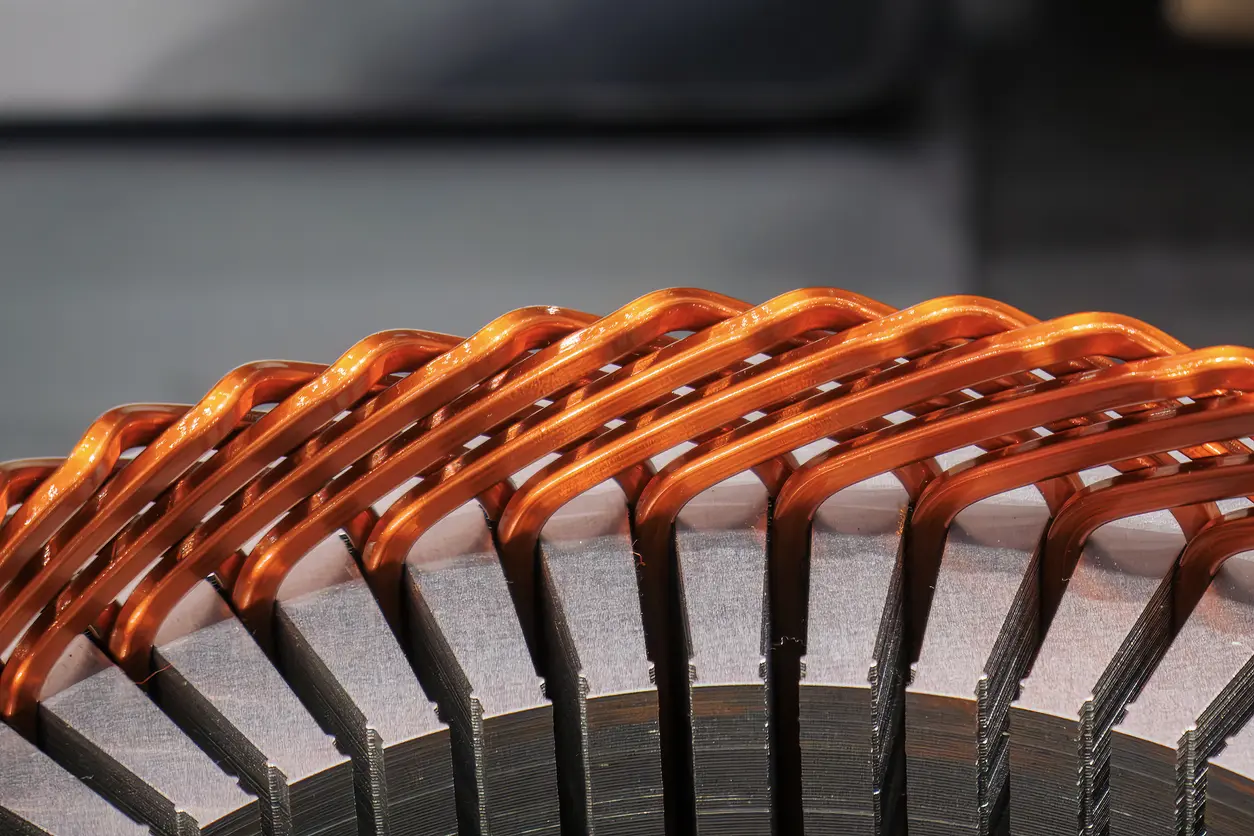

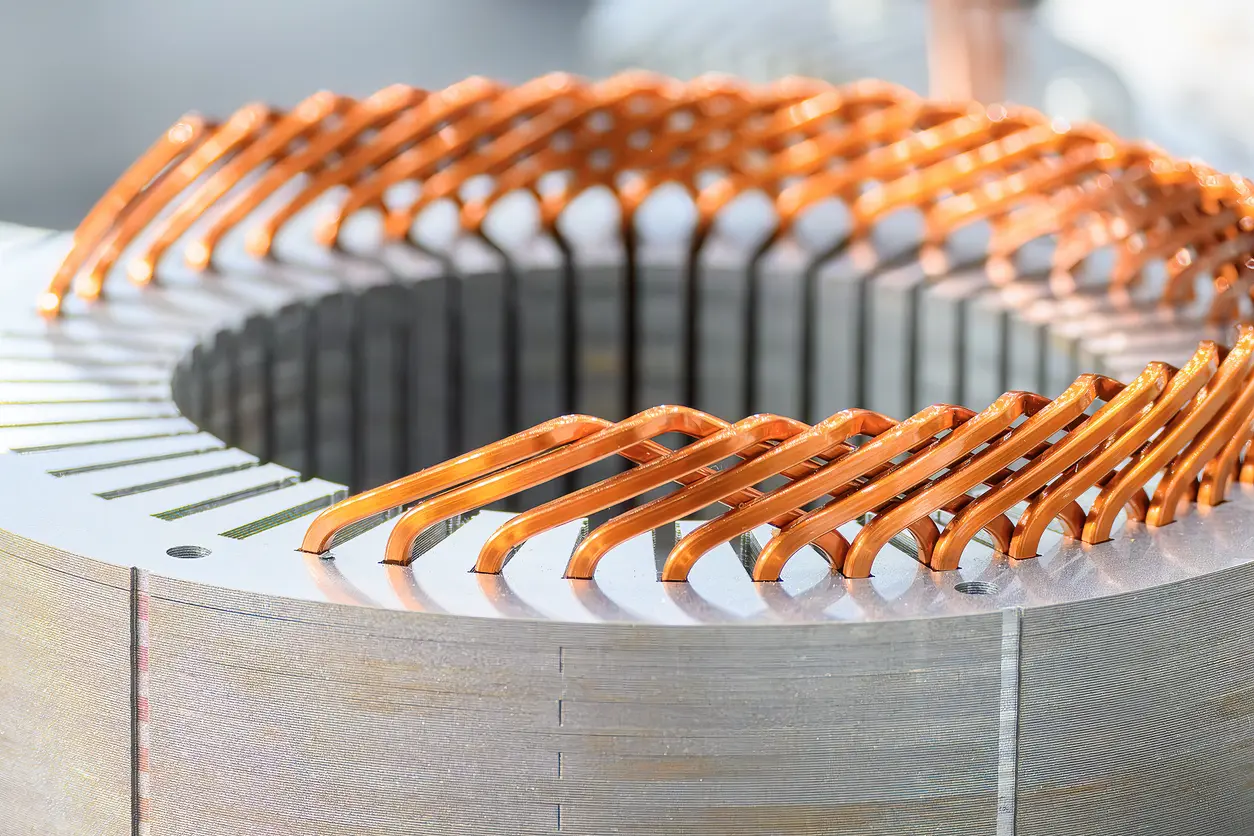

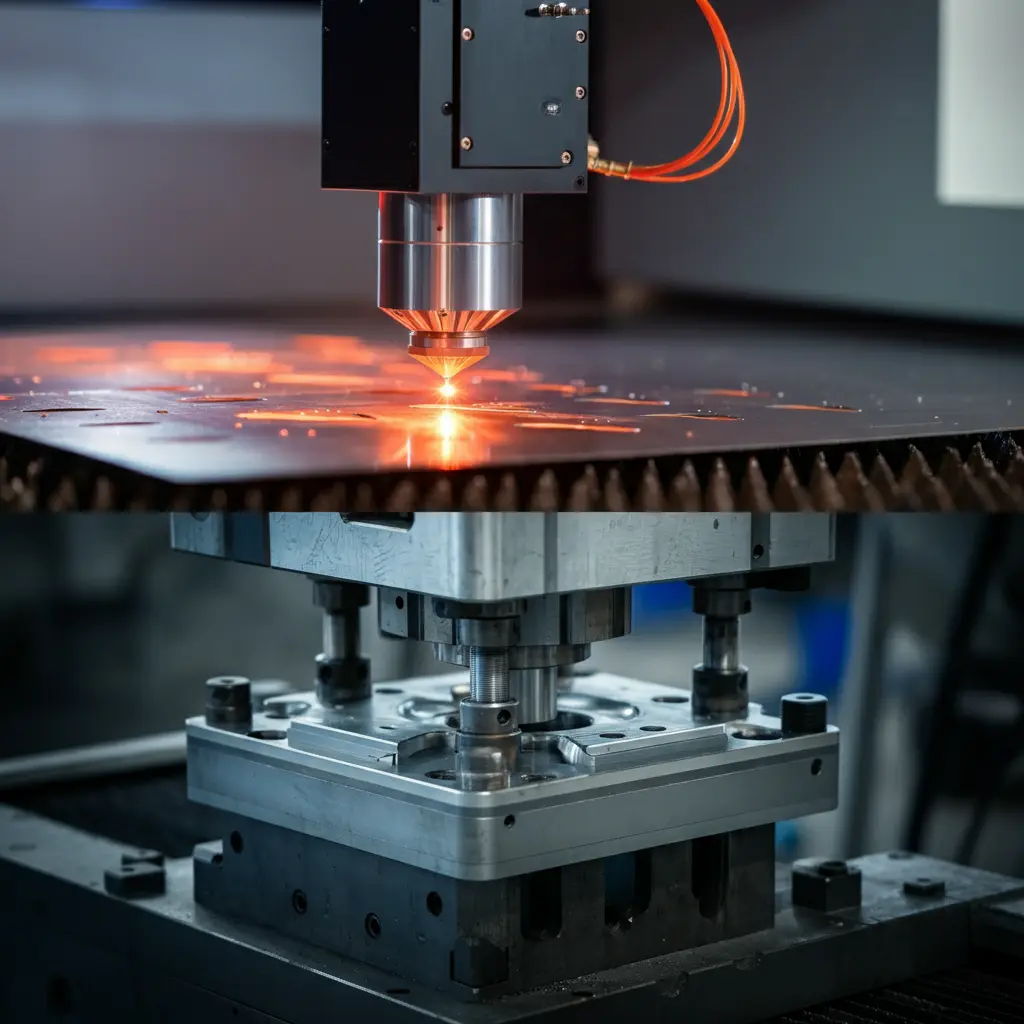

2.3 Motor Efficiency

The motor is the core component of the drone’s power system, and its efficiency directly affects power consumption. Brushless motors are generally more efficient than brushed motors because they do not suffer from brush friction and have a longer lifespan. Therefore, choosing efficient brushless motors helps improve endurance.

Factors affecting motor efficiency include:

- Motor Speed (RPM): Higher speeds consume more power. Selecting an RPM suitable for the task helps conserve energy.

- Motor Quality: High-quality motors offer more stable performance and better energy conversion efficiency.

Pairing the motor with appropriately sized and high-quality propellers also reduces motor load. For example, larger-diameter propellers are more efficient at low speeds, while carbon fiber propellers provide better rigidity and lightweight properties.

2.4 Environmental Conditions

Drone endurance is heavily influenced by environmental conditions, especially wind speed, temperature, and altitude.

- Wind Speed: Flying against the wind increases motor load and power consumption. Choosing low-wind conditions or adjusting the flight angle helps reduce energy usage.

- Temperature: Cold environments reduce battery discharge efficiency, shortening flight time, while high temperatures can cause battery overheating and affect battery life.

- Altitude: At high altitudes, thinner air reduces the lift generated by the propellers, requiring higher motor speeds to maintain flight, thereby increasing energy consumption.

Planning flight times and locations to avoid extreme weather and high wind speeds helps improve drone endurance.

2.5 Flight Modes and Operating Habits

A drone’s flight mode and operating habits also impact its endurance. Common flight modes include GPS Mode, Stabilized Mode, and Sport Mode:

- GPS Mode: Offers automatic stabilization and positioning, suitable for beginners, but consumes more power.

- Stabilized Mode: Manual control without GPS assistance, suitable for energy-efficient flying.

- Sport Mode: High-speed and high-maneuverability operations consume more power, reducing flight time.

Good operating habits, such as maintaining smooth flight and minimizing sudden accelerations and stops, can effectively conserve power. Additionally, planning efficient flight paths and avoiding unnecessary turns and prolonged hovering also contribute to improved endurance.

3.Methods to Improve Electric Drone Endurance

3.1 Choosing High-Performance Batteries

Batteries are crucial in determining the endurance of electric drones. Therefore, selecting high-performance batteries suited to the mission’s needs is essential. The most common types of drone batteries on the market are Lithium Polymer (LiPo) batteries and Lithium-Ion (Li-ion) batteries. LiPo batteries offer high discharge rates and lightweight properties, making them ideal for drones requiring high instantaneous power. Li-ion batteries, on the other hand, have a longer lifespan and more stable discharge performance, making them suitable for long-duration flights.

Key Considerations for Battery Selection

- Energy Density: Choose batteries with high energy density to provide more power without adding extra weight.

- Discharge Rate (C-rating): Select the appropriate discharge rate for the drone’s power needs to avoid battery damage from rates that are too high or too low.

- Battery Protection Technology: Batteries equipped with a Battery Management System (BMS) prevent overcharging and over-discharging, extending battery life.

Battery Maintenance Tips

- Avoid Over-Discharging: Keep battery levels above 20% to prevent complete depletion.

- Proper Storage: When not in use for long periods, store batteries at about 50% charge.

- Temperature Control: Charge and discharge batteries in suitable temperature ranges to avoid extreme heat or cold.

3.2 Optimizing Drone Design

A drone’s design has a significant impact on endurance, especially concerning the materials and structure of the body. Lightweight design effectively reduces energy consumption, extending flight time.

Material Selection

- Carbon Fiber: Lightweight and strong, commonly used for drone arms and frames in high-performance models.

- Magnesium Alloy: Offers excellent structural strength and weight reduction, suitable for frames and support structures.

Aerodynamic Design

- Streamlined Body: Reduces air resistance, making the drone more energy-efficient during flight.

- Foldable Design: Makes drones easier to carry and store, reducing potential wear and tear during transport.

3.3 Using High-Efficiency Motors and Propellers

A drone’s power system consists of motors and propellers, and their efficiency directly impacts endurance.

Choosing Efficient Motors

- Brushless Motors: Compared to brushed motors, brushless motors offer higher energy conversion efficiency and a longer lifespan.

- Low-Loss Design: Select motors with efficient cooling and low internal resistance to minimize energy loss.

Selecting Suitable Propellers

- Material Choice: Carbon fiber propellers are lightweight and rigid, improving flight efficiency.

- Size Matching: Choose the appropriate diameter and pitch based on mission requirements to reduce motor load.

3.4 Improving Flight Techniques

Effective piloting techniques can help conserve power and extend drone endurance.

Energy-Saving Flight Strategies

- Smooth Flight: Avoid frequent accelerations and stops, maintaining a stable speed and altitude.

- Route Planning: Plan flight paths in advance to minimize unnecessary turns and detours.

Reducing Hovering Time

- Extended hovering consumes significant power. Whenever possible, minimize the time the drone remains stationary in the air.

3.5 Utilizing Solar and Hybrid Power Technologies

Advancements in technology allow drone endurance to be further improved using solar and hybrid power systems.

Solar Power Technology

- Solar Panels: Install high-efficiency solar panels on drone wings to charge the battery using solar energy.

- Applications: Ideal for tasks requiring continuous flight, such as long-term monitoring and mapping.

Hybrid Power Systems

- Combining Internal Combustion Engines and Batteries: Integrate a small internal combustion engine with a battery to provide additional power during long flights.

- Advantages: Suitable for industrial-grade drones that require long-distance flight or heavy payloads.

By applying these methods, drone endurance can be effectively enhanced, meeting the demands of various application scenarios.

4.Practical Cases of Electric Drone Endurance

4.1 Comparison of Endurance Times for Common Commercial Drones

In commercial applications, different drone brands and models vary in endurance depending on their design and function. The following is a comparison of endurance times for several mainstream commercial drones to help readers understand their real-world performance:

DJI Matrice 300 RTK

- Endurance Time: Up to 55 minutes of flight time.

- Application Scenarios: Suitable for mapping, inspections, and search-and-rescue missions, with strong payload capacity and stable flight performance.

Parrot Anafi USA

- Endurance Time: Approximately 32 minutes of continuous flight.

- Application Scenarios: Ideal for outdoor patrols, surveillance, and environmental monitoring, with high-resolution imaging capabilities.

SenseFly eBee X

- Endurance Time: Up to 90 minutes, making it a top choice among fixed-wing drones.

- Application Scenarios: Primarily used for large-scale terrain mapping and agricultural monitoring, offering highly efficient flight capabilities.

Autel EVO II Pro

- Endurance Time: About 40 minutes, suitable for high-resolution image capture.

- Application Scenarios: Ideal for aerial photography, filmmaking, and industrial inspections.

The endurance differences among these drones are mainly influenced by battery capacity, weight, design, and intended applications. Selecting the appropriate drone can effectively improve work efficiency and reduce interruptions and return-to-base frequency.

4.2 Successful Application Cases

Surveying and Geographic Information Systems (GIS)

Drones are widely used in the surveying industry to quickly generate high-resolution maps and 3D terrain models.

Case Study: A company conducted a survey of a large mining area using the SenseFly eBee X. A single flight covered approximately 500 hectares, significantly improving surveying efficiency and shortening the project timeline. Its 90-minute endurance reduced the need for frequent battery changes, ensuring continuous and accurate data collection.

Agricultural Monitoring

In agriculture, drones are used for monitoring crop health, detecting pests, and spraying pesticides.

Case Study: For large-scale farmland operations, the DJI Agras T30 was used for spraying tasks. Each flight lasted approximately 30 minutes, covering up to 16 hectares per session. This greatly increased agricultural productivity while reducing labor costs and time.

Infrastructure Inspection

Drones play a critical role in inspecting infrastructure like power lines, bridges, and buildings.

Case Study: During a high-voltage power line inspection, an engineering team used the DJI Matrice 300 RTK. Its 55-minute endurance allowed for long-distance inspections, and with a thermal imaging camera, faults were quickly identified, avoiding the high risks associated with traditional inspection methods.

Search and Rescue Missions

Drones enhance search-and-rescue operations by quickly scanning large areas, improving rescue efficiency.

Case Study: In a mountainous search for a missing person, the rescue team used the Parrot Anafi USA. Its 32-minute flight endurance and high-resolution imaging capabilities helped rescuers locate the target quickly, saving lives.

Environmental Monitoring

Drones are also used for monitoring air quality, water pollution, and forest conservation.

Case Study: An environmental organization used the Autel EVO II Pro to conduct water pollution detection in wetlands. The drone’s 40-minute flight time allowed it to capture high-precision images and data, effectively tracking pollution sources and developing remediation plans.

These successful cases demonstrate that drone endurance is crucial for improving work efficiency and task completion rates across industries. Selecting the right drone based on mission requirements can yield significant real-world benefits.

※Further Reading: Drone Motor Core: 6 Essential Ways to Enhance Efficiency and Flight Time

External Links: https://www.researchgate.net/publication/366691991_Multi-Criteria_Coordinated_Electric_Vehicle-Drone_Hybrid_Delivery_Service_Planning