Discover how self bonding stacking technology is revolutionizing electric vehicle performance by enhancing motor efficiency, extending battery life, and increasing driving range. Learn about the benefits of self bonding stacking and its impact on the future of sustainable transportation.

1. Introduction

1.1. Overview of Electric Vehicles (EVs)

a. Rise in Global Adoption of EVs

The global automotive industry is undergoing a significant transformation as electric vehicles (EVs) become increasingly prevalent. Governments worldwide are implementing policies to reduce carbon emissions, leading to a surge in EV adoption. Consumers are also more environmentally conscious, opting for vehicles that offer sustainability without compromising performance.

b. Importance of Motor Efficiency in EV Performance

At the heart of every electric vehicle is its motor, a critical component that directly influences performance, efficiency, and driving experience. Motor efficiency determines how effectively electrical energy from the battery is converted into mechanical energy to propel the vehicle. Higher efficiency means less energy wasted, resulting in extended battery life and longer driving ranges.

1.2. Challenges in EV Motor Efficiency

a. Energy Losses in Traditional Motor Designs

Traditional motor designs often suffer from energy losses due to factors like eddy currents and hysteresis in the motor core. These losses generate unwanted heat and reduce the overall efficiency of the motor. Conventional lamination methods, such as adhesive bonding and welding, may not adequately address these issues, leading to suboptimal motor performance. According to a recent study, “diverse electric motor researches analyze the efficiency of four types of electric motors, highlighting the limitations and features of each motor in the context of electric vehicles” (Electric_Motor_Systems_…). This analysis underscores the need for innovative technologies like Self Bonding Stacking to minimize energy losses and improve motor efficiency.

b. Impact on Battery Life and Driving Range

Inefficient motors place a greater demand on the EV’s battery system, causing faster depletion of battery life. This not only shortens the distance an EV can travel on a single charge but also accelerates battery degradation over time. Improving motor efficiency is therefore essential for enhancing battery longevity and maximizing driving range.

2. What is Self Bonding Stacking Technology?

2.1. Definition and Basics

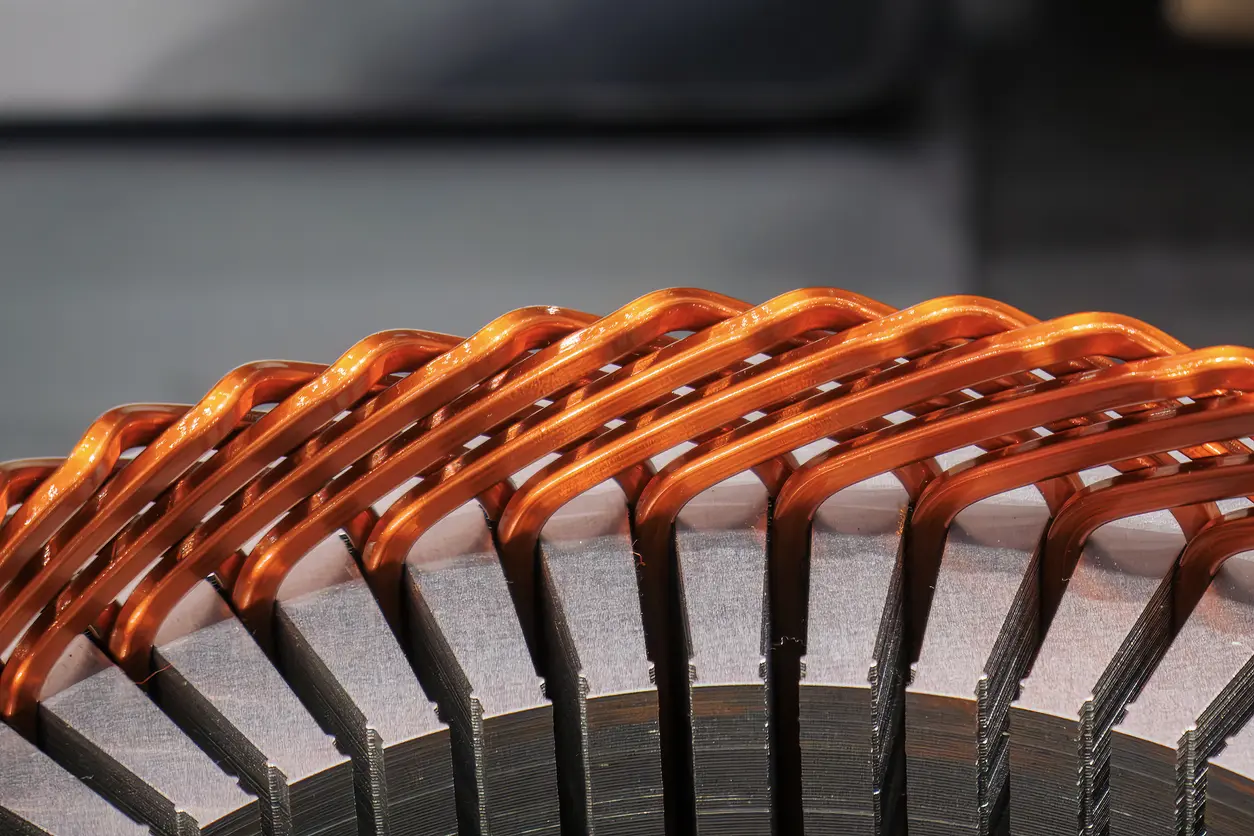

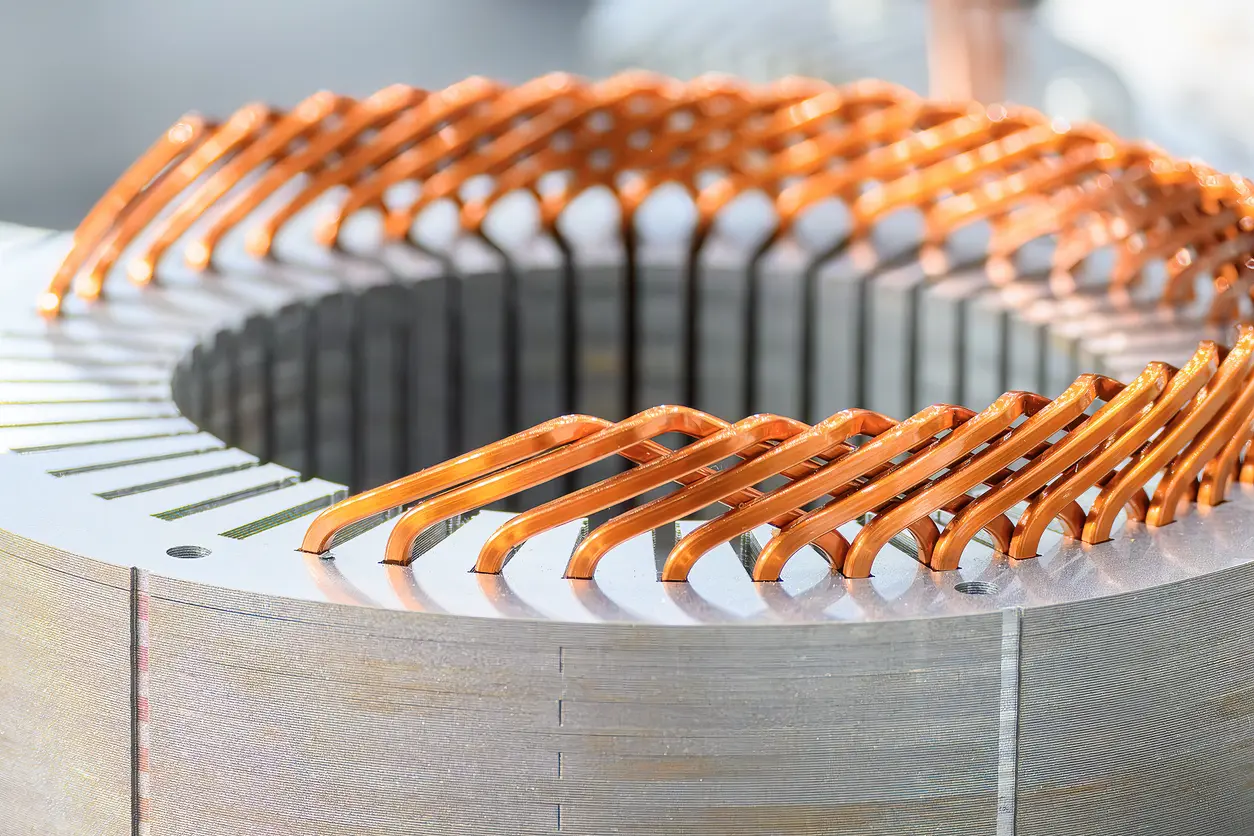

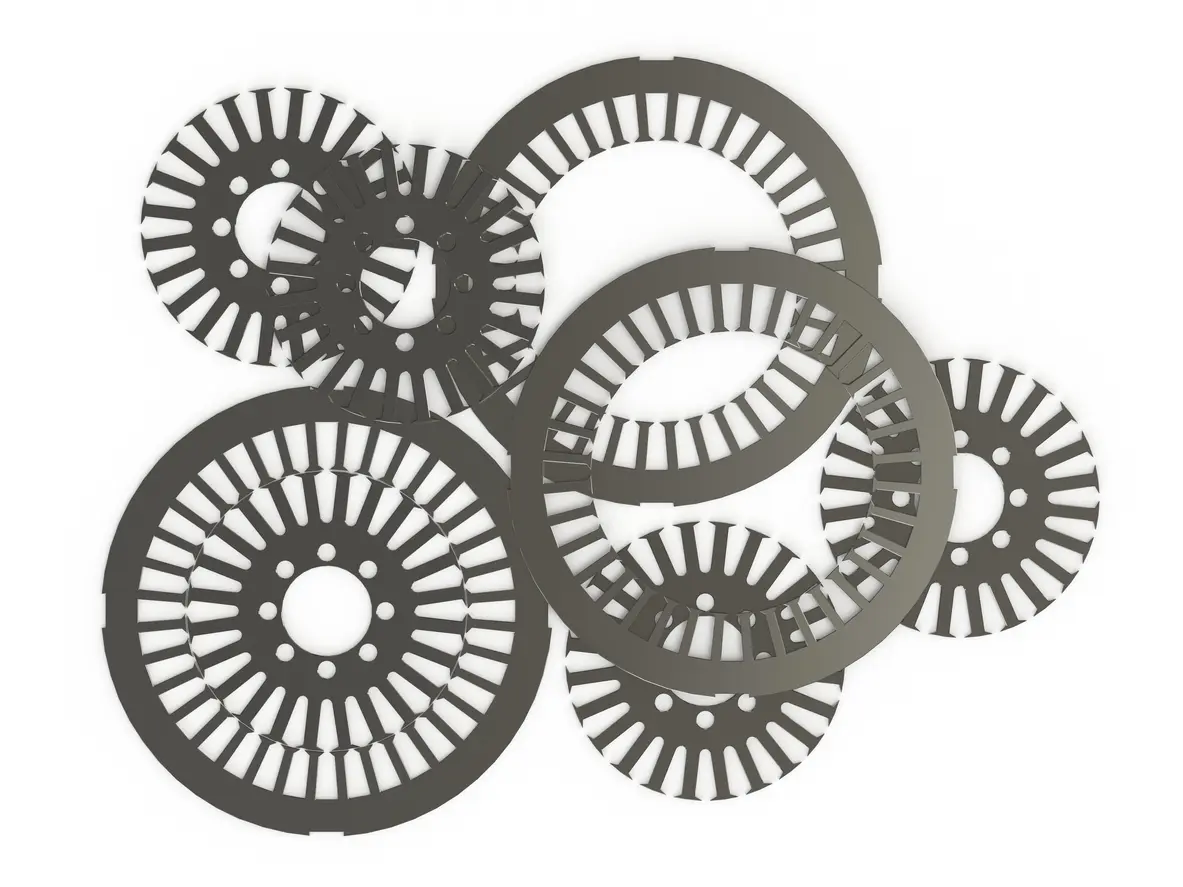

a. Explanation of Lamination in Electric Motors

Lamination in electric motors involves stacking thin sheets of electrical steel to form the core. This process minimizes energy losses by reducing eddy currents, which are loops of electrical current induced within conductors by a changing magnetic field. Proper lamination is crucial for achieving high motor efficiency.

b. Introduction to Self Bonding Stacking

Self Bonding Stacking is an innovative technology that enhances the lamination process. It utilizes self bonding electrical steel, which is coated with a special insulating layer that activates under heat. This allows the steel sheets to bond directly to each other without the need for additional adhesives or mechanical fasteners, forming a cohesive and efficient motor core.

2.2. How It Differs from Traditional Methods

a. Elimination of Adhesives and Mechanical Bonding

Traditional lamination methods often rely on adhesives, welding, or mechanical fastening to hold the layers together. These methods can introduce additional weight, potential points of failure, and inefficiencies. Self Bonding Stacking eliminates these issues by bonding layers through heat activation, resulting in a more streamlined and reliable assembly.

b. Integration of Insulation Directly into Laminations

In Self Bonding Stacking, the insulation is integrated directly into the electrical steel sheets through a specialized coating. This integration enhances the insulation between layers, reducing energy losses and improving the overall magnetic properties of the motor core.

3. Benefits of Self Bonding Stacking in EV Motors

3.1. Improved Efficiency

a. Reduction of Eddy Current Losses

By creating a tightly bonded and insulated core, Self Bonding Stacking significantly reduces eddy current losses. The uniform bonding ensures minimal gaps between layers, enhancing magnetic flux and allowing the motor to operate more efficiently.

b. Enhanced Magnetic Properties

The improved lamination process enhances the magnetic properties of the motor core. Better magnetic permeability leads to more effective energy conversion, contributing to higher motor efficiency and performance.

3.2. Extended Battery Life

a. Lower Energy Consumption Due to Efficient Motors

An efficient motor requires less electrical energy to produce the same mechanical output. This means the battery is less taxed during operation, conserving energy and extending the time between charges.

b. Reduced Strain on Battery Systems

By operating more efficiently, the motor places less strain on the battery system. This reduction in demand can prolong the overall lifespan of the battery, delaying the need for replacement and reducing long-term ownership costs.

4. Technical Aspects of Self Bonding Stacking

4.1. Materials Used

a. Advanced Magnetic Steels

Self Bonding Stacking utilizes advanced magnetic steels with high permeability and low core losses. These materials are essential for achieving the desired magnetic performance and efficiency in EV motors.

b. Specialized Insulating Coatings

The electrical steel sheets are coated with specialized insulating materials that activate under heat. This coating facilitates the self bonding process and enhances insulation between layers, contributing to the overall efficiency of the motor.

4.2. Manufacturing Process

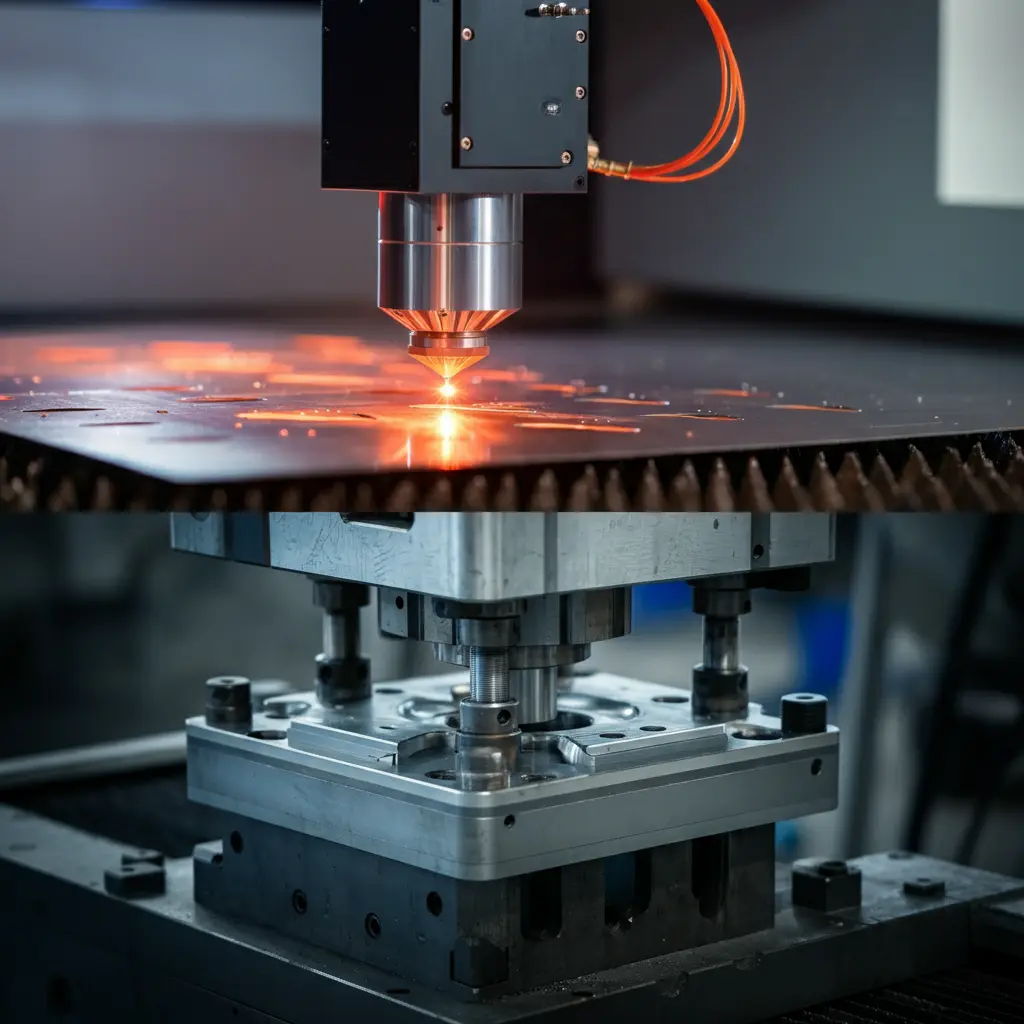

a. Layering and Bonding Techniques

The manufacturing process involves stacking the coated steel sheets and applying precise heat to activate the bonding layer. This creates a solid, cohesive core without the need for adhesives or mechanical fasteners.

b. Quality Control Measures

Implementing stringent quality control measures is vital to ensure the consistency and reliability of the Self Bonding Stacking process. This includes monitoring temperature controls, bonding integrity, and material quality throughout production.

5. Future Outlook

5.1. Technological Advancements

a. Ongoing Research and Development

Research and development efforts continue to refine Self Bonding Stacking technology. Innovations focus on enhancing material properties, optimizing manufacturing processes, and further improving motor efficiency.

b. Potential Innovations in Material Science

Advancements in material science may lead to new coatings and steel compositions that enhance the self bonding process. These innovations have the potential to unlock even greater efficiencies and performance gains.

5.2. Impact on the EV Industry

a. Setting New Standards for Motor Efficiency

As Self Bonding Stacking technology becomes more widespread, it may set new industry standards for motor efficiency. Manufacturers adopting this technology can gain a competitive edge by offering superior performance.

b. Contribution to Sustainable Transportation

Improving motor efficiency aligns with global efforts to promote sustainable transportation. By reducing energy consumption and extending driving ranges, Self Bonding Stacking supports the broader adoption of EVs and the transition to a greener future.

6. Conclusion

6.1. Recap of Key Benefits

a. Efficiency Gains

Self Bonding Stacking technology offers significant efficiency gains by reducing energy losses and enhancing magnetic properties in EV motors.

b. Driving Range Enhancement

Improved motor efficiency leads to increased driving ranges, providing greater convenience and flexibility for EV drivers.

6.2. Final Thoughts

a. The Role of Self Bonding Stacking in Future EV Development

Self Bonding Stacking stands as a promising advancement in EV technology. Its ability to enhance motor performance and efficiency positions it as a key contributor to future EV development.

b. Encouraging Industry-Wide Adoption for Better Performance

Industry-wide adoption of Self Bonding Stacking can lead to significant improvements in EV performance, customer satisfaction, and environmental impact. Embracing this technology may pave the way for a new era of efficient and sustainable electric transportation.

Reference

Devi, M., & Bagyaveereswaran, V. (2023). Electric Motor Systems: Relative Study on Diverse Motors in Electric Vehicles. 2023 Innovations in Power and Advanced Computing Technologies (i-PACT), IEEE. DOI: 10.1109/I-PACT58649.2023.10434509.