Unlock the potential of your drone with the Drone Motor Core. Discover 7 essential ways it boosts efficiency and extends flight time.

1. Introduction

1.1 Overview of Drone Motor Core Technology

a. Importance of Motor Cores in Drones

The motor core is at the heart of every modern drone, playing a critical role in its operation and performance. By converting electrical energy into mechanical power, it generates the necessary thrust for drones to take off, maneuver, and maintain stable flight. Without an efficient and powerful motor core, even the most advanced drones would struggle to perform their tasks effectively. According to Drone Industry Insights, advancements in motor core technology have significantly impacted the capabilities of drones across various industries.

1.2 Purpose of the Article

a. Explain the Impact of Motor Cores on Efficiency and Flight Time

This article aims to shed light on the crucial impact that motor cores have on the efficiency and flight time of drones. Understanding how these components influence performance is essential for manufacturers, hobbyists, and professional operators alike. By delving into the specifics of motor cores, their efficiency, and their effect on drone performance, we provide valuable insights to help optimize drone design and usage. Enhancing knowledge in this area is vital not only for improving performance but also for maximizing the operational lifespan and reliability of drones.

2. Basic Concepts of Drone Motor Cores

2.1 Definition of a Drone Motor Core

a. What Is a Motor Core?

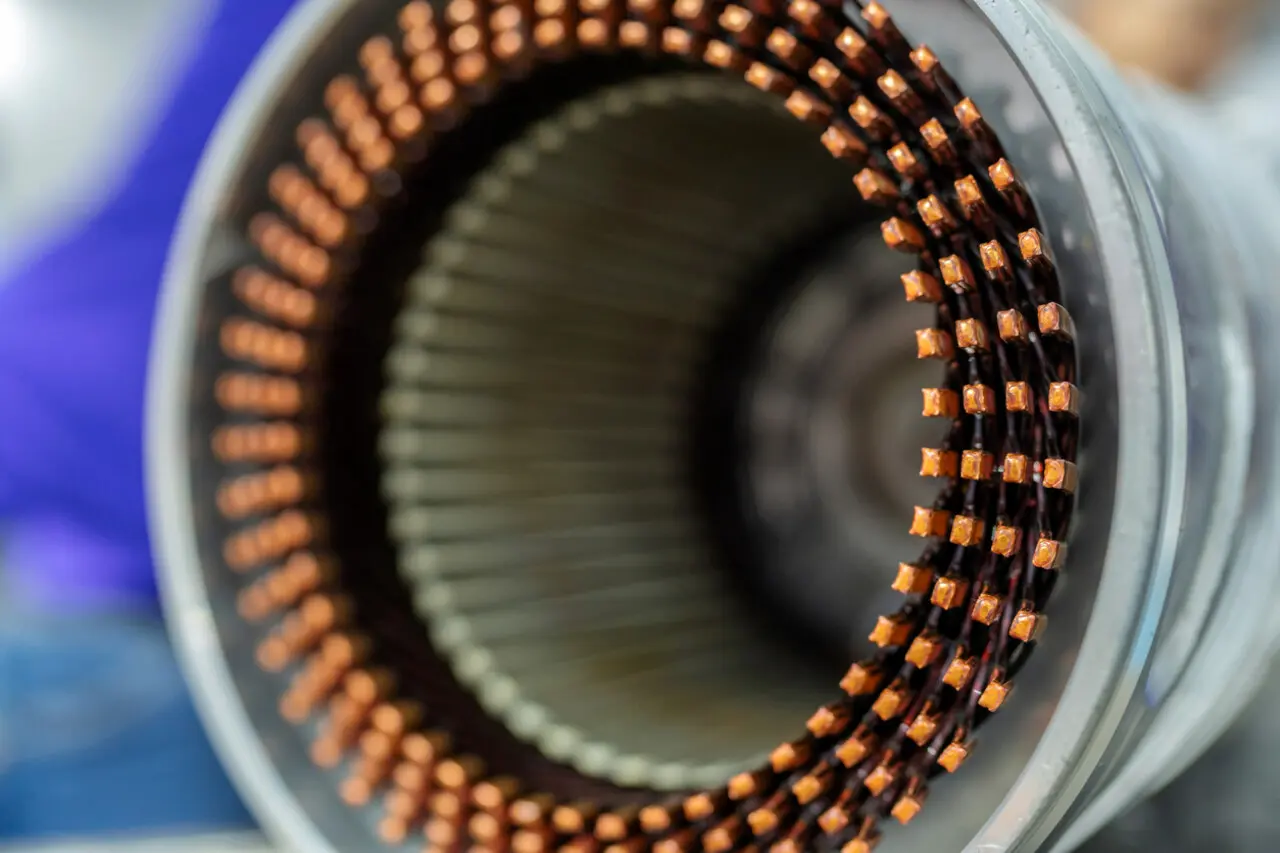

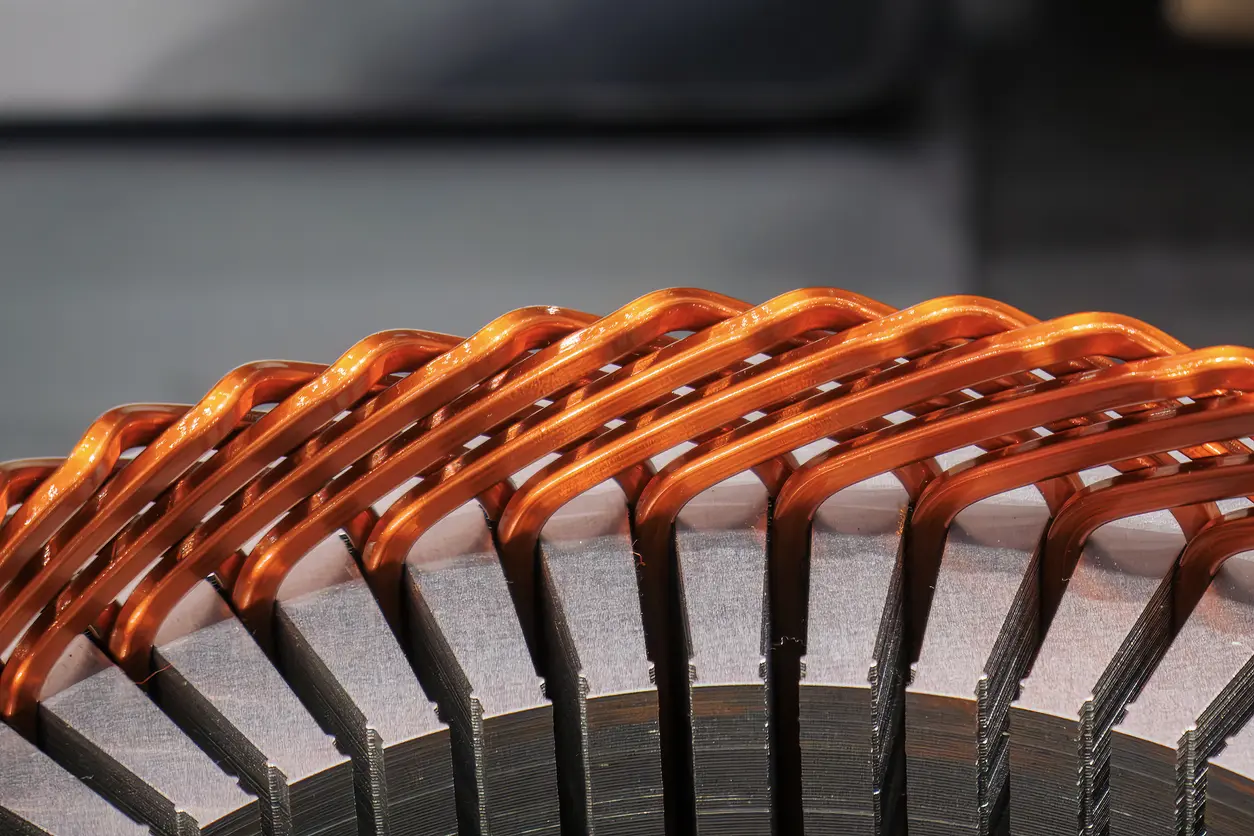

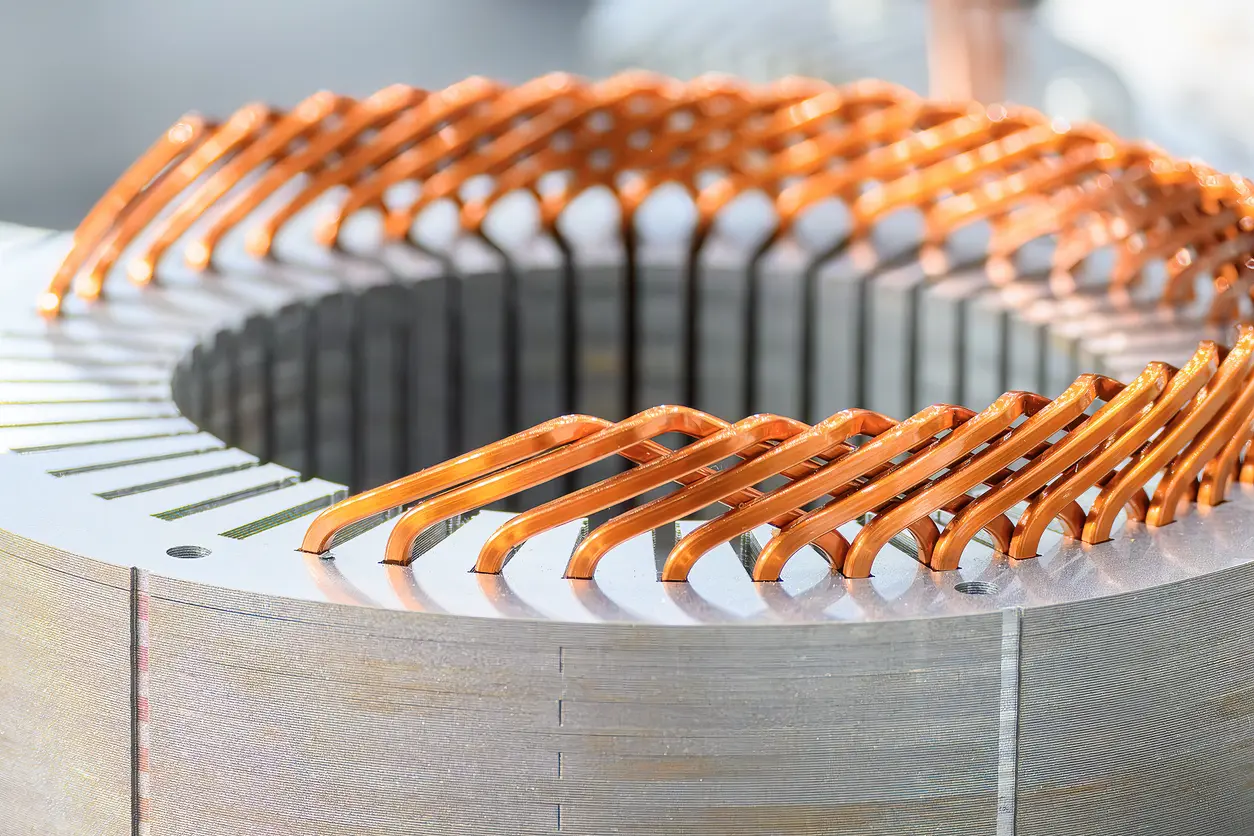

The motor core is a fundamental component of the electric motors used in drones. It consists of thin laminations of electrical steel, stacked together to form a cylindrical structure. This core houses the windings through which electric current flows, generating a magnetic field that interacts with the rotor, causing it to spin. The efficiency and performance of the motor core directly influence the drone’s ability to generate thrust, affecting its lift, maneuverability, and overall flight dynamics. As explained by Drone Nodes, the motor core’s design and materials are crucial for optimal drone performance.

2.2 Types of Drone Motor Cores

a. Brushed vs. Brushless Motors

There are two primary types of motor cores used in drones: brushed and brushless.

- Brushed Motors: These are the older technology and consist of brushes that make electrical contact with the commutator on the rotor. The brushes facilitate the flow of current, creating the necessary magnetic interaction for the motor to operate. Brushed motors are simpler and cheaper but suffer from wear and tear due to friction, leading to shorter lifespans and higher maintenance needs. They are often used in lower-cost or entry-level drones where budget constraints are a primary consideration.

- Brushless Motors: Brushless motors utilize electronic controllers to manage current flow, eliminating the need for brushes. This design reduces friction and wear, resulting in higher efficiency, longer lifespan, and greater reliability. Brushless motors are known for their superior performance, offering faster speeds and better control. These attributes make them the preferred choice for high-performance and professional-grade drones, where precision and efficiency are paramount.

Understanding the differences between brushed and brushless motor cores is essential for selecting the appropriate motor for specific drone applications, ensuring optimal performance and longevity.

3. Factors Affecting Drone Efficiency

3.1 Motor Core Efficiency

a. Electrical to Mechanical Energy Conversion

The efficiency of a drone’s motor core is pivotal in converting electrical energy into mechanical energy. This process determines how effectively a motor can transform the power from the battery into thrust, directly impacting the drone’s performance. Efficient motor cores ensure that more energy is used for propulsion rather than being lost as heat. This conversion efficiency affects not only the drone’s power output but also its overall operational time. High-efficiency motors can significantly extend flight time, allowing drones to stay airborne longer and perform tasks more effectively.

3.2 Heat Dissipation in the Drone Motor

a. Role in Managing Heat

Heat dissipation is another crucial factor affecting the efficiency of the drone motor. During operation, motors generate heat, and if not managed properly, this heat can lead to performance degradation or even motor failure. Features such as integrated cooling fins or the use of heat-resistant materials can enhance heat management. Proper heat dissipation not only prolongs the life of the motor but also maintains consistent performance, allowing drones to operate smoothly over extended periods.

Understanding these factors—energy conversion efficiency, weight and material composition, and heat dissipation—provides valuable insights into optimizing drone performance. By selecting and designing motor cores with these considerations in mind, manufacturers can enhance the efficiency and reliability of their drones, ensuring they meet the demands of various applications.

4. Impact on Flight Time

4.1 Power Consumption

a. How Motor Affect Battery Life

The power consumption of a drone’s motor directly influences its battery life and, consequently, its flight time. Motors that convert electrical energy into mechanical energy efficiently require less power to generate the necessary thrust. This efficiency reduces the drain on the battery, extending the drone’s operational duration. Conversely, inefficient motors consume more power, depleting the battery faster and shortening flight time. Selecting high-efficiency motor cores is crucial for maximizing the endurance of a drone, especially for tasks requiring prolonged flight periods.

4.2 Thrust-to-Weight Ratio

a. Optimization for Longer Flight Times

The thrust-to-weight ratio of a drone is a critical determinant of its flight performance and time aloft. A higher thrust-to-weight ratio means that the motors can generate sufficient lift to overcome the drone’s weight with less effort, which is particularly beneficial for maintaining altitude and maneuvering efficiently. Optimizing this ratio involves choosing motor cores that are effective at providing adequate thrust while keeping the drone’s weight to a minimum. By achieving an optimal thrust-to-weight ratio, drones can perform more efficiently, consume less power, and ultimately enjoy longer flight times.

5. Selecting the Right Motor Core for Optimal Efficiency

5.1 Matching Motor Core to Drone Type

a. Considerations for Different Drone Applications

Choosing the right motor core involves matching it to the specific type of drone and its intended application. Different drones require different motor characteristics to perform optimally. For example, racing drones need high-speed motors with a high KV rating to achieve rapid acceleration and agility. In contrast, photography drones benefit from motors that offer smooth and stable flight, often with lower KV ratings for precise control. Industrial drones used for heavy lifting or surveying require motors that provide significant torque and can handle substantial payloads. Understanding the specific needs of each application ensures that the motor core selected will enhance the drone’s performance and efficiency.

5.2 Balancing Performance and Efficiency

a. Trade-offs Between Power and Endurance

Balancing performance and efficiency is crucial when selecting a motor core. High-performance motors deliver greater power and speed but may consume more energy, reducing flight time. On the other hand, motors designed for efficiency prioritize lower power consumption, extending battery life but potentially sacrificing some performance capabilities. The key is to find a balance that suits the drone’s primary use. For instance, a hobbyist drone may prioritize performance for fun and excitement, while a commercial drone might prioritize efficiency to maximize operational time and reduce maintenance costs. Evaluating the trade-offs between power and endurance helps in selecting a motor core that provides the best overall value for the specific use case.

5.3 Considering Environmental Factors

a. Selecting Motor Cores Based on Operating Conditions

Environmental factors play a significant role in selecting the appropriate motor core for a drone. Drones operating in extreme conditions—such as high altitudes, temperature extremes, or dusty environments—require motor cores designed to withstand these specific challenges. Although the motor core itself usually wouldn’t be exposed to the external environment outside the motor housing, it would be beneficial to take it into consideration while designing. For example, motor cores made from materials with high thermal conductivity can improve heat dissipation in hot climates, preventing overheating and maintaining efficiency. In cold conditions, selecting materials that retain magnetic properties at low temperatures ensures consistent motor performance.

6. Conclusion

6.1 Recap of Key Points

a. Summary of Motor Core Impact on Efficiency and Flight Time

In summary, the motor core is a pivotal component in determining a drone’s efficiency and flight time. Efficient motor cores optimize the motor conversion of electrical energy into mechanical energy, enhancing overall performance and prolonging battery life. Effective heat dissipation mechanisms ensure that the motors operate within safe temperature ranges, preventing overheating and maintaining consistent performance. Furthermore, understanding the thrust-to-weight ratio and aerodynamic efficiency helps in selecting motor cores for drone motors that maximize flight time and stability.

For those looking to optimize their drone’s performance with high-quality motor cores, our company offers expert guidance and top-notch material tailored to your needs. If you are seeking core laminations for your drone’s motor core, we are here to help. Additionally, staying updated with resources such as Drone Industry Insights and Drone Nodes will help you navigate the evolving landscape of drone technology.

References

- Drone Industry Insights. (n.d.). Retrieved from https://droneii.com/

- Drone Nodes. (n.d.). Retrieved from https://dronenodes.com/