This article delves into the application of EV motor cores and stator core laminations in EVs. It covers their basic definition, structure, role in motors, future technological trends, and the success stories of leading EV manufacturers. Together, these elements provide a comprehensive analysis of why this technology is vital to the future of EVs.

1. Growth of the Electric Vehicle Market

1.1 Current Status and Trends

The EV market is growing at an impressive rate. Over the past five years, global EV sales have shown continuous growth, driven primarily by environmental policies, advances in battery technology, and the increasing consumer demand for clean energy transportation. The development of EVs is supported by government initiatives across major markets such as China, Europe, and North America, which have introduced purchase subsidies, improved charging infrastructure, and implemented emission regulations.

It is anticipated that the EV market will continue to expand rapidly over the next decade, transforming the automotive industry. As EVs become more common, the demand for efficient, high-performing components like EV motor cores and stator core laminations will grow.

1.2 The Importance of EV Technology

Electric vehicles have gained attention for their ability to reduce greenhouse gas emissions and reliance on fossil fuels, making them an essential part of addressing global environmental concerns. Significant improvements in battery technology, charging speeds, and driving ranges have all enhanced the feasibility and attractiveness of EVs. Alongside these advancements, motor technology has also seen major breakthroughs, with particular emphasis on enhancing efficiency through components like EV motor cores and stator core laminations.

In a recent study from Concordia University, researchers developed an innovative motor design using soft magnetic composite (SMC) materials that improve torque output while reducing copper losses. The design, which focuses on optimizing stator and rotor configurations, promises to make motors more compact and cost-effective, further contributing to advancements in EV performance(Concordia University).

2. Defining Stator Core Laminations and EV Motor Cores

2.1 What Are Stator Core Laminations?

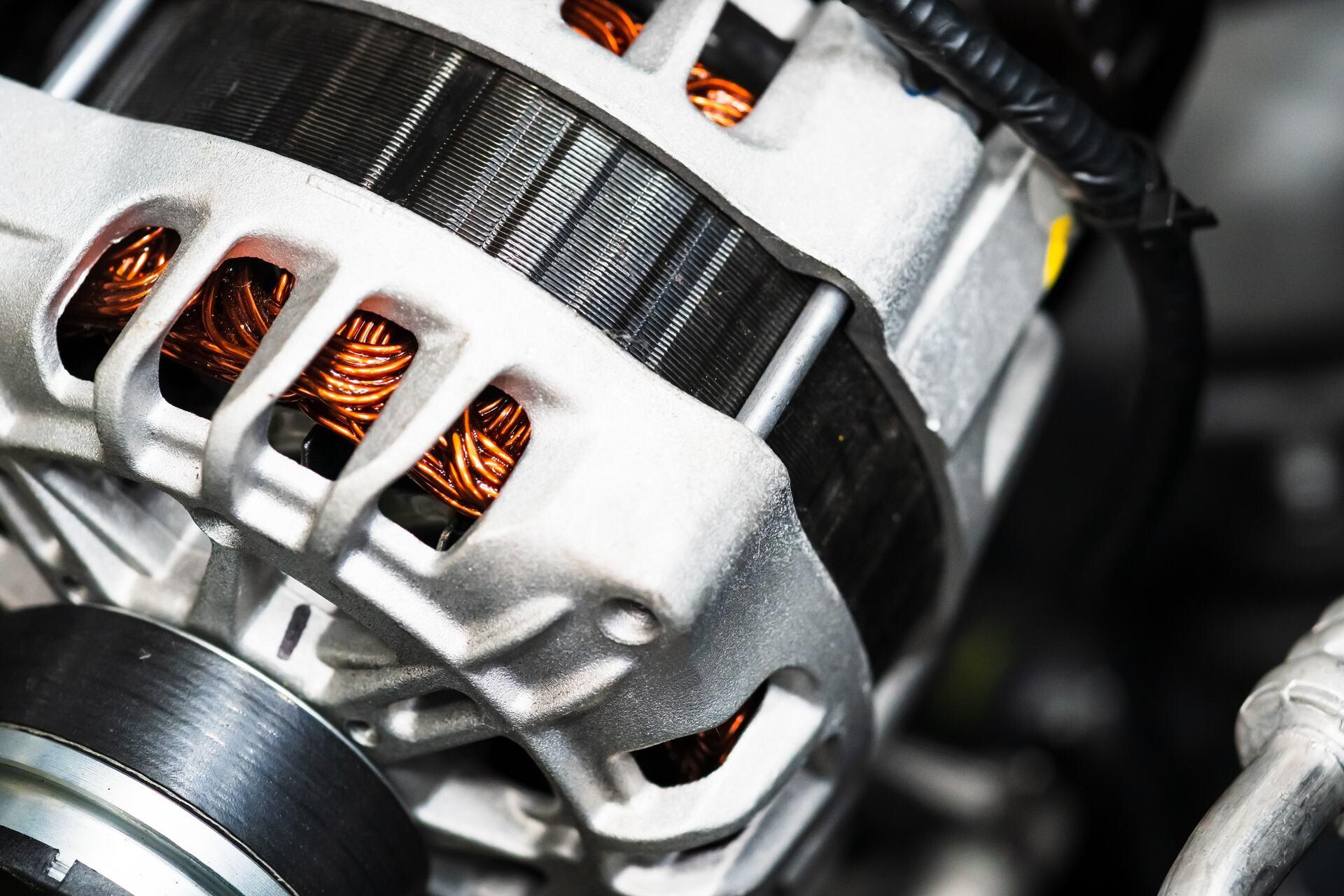

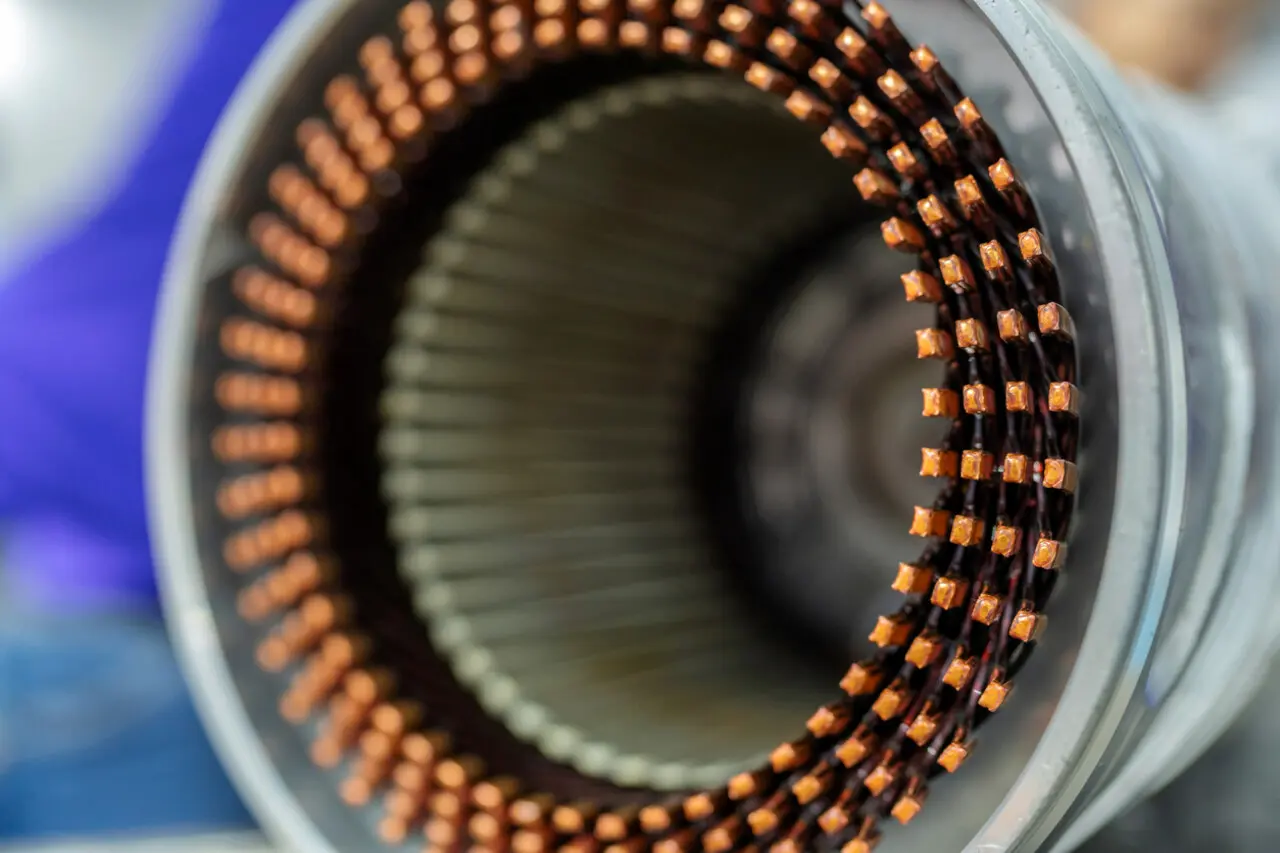

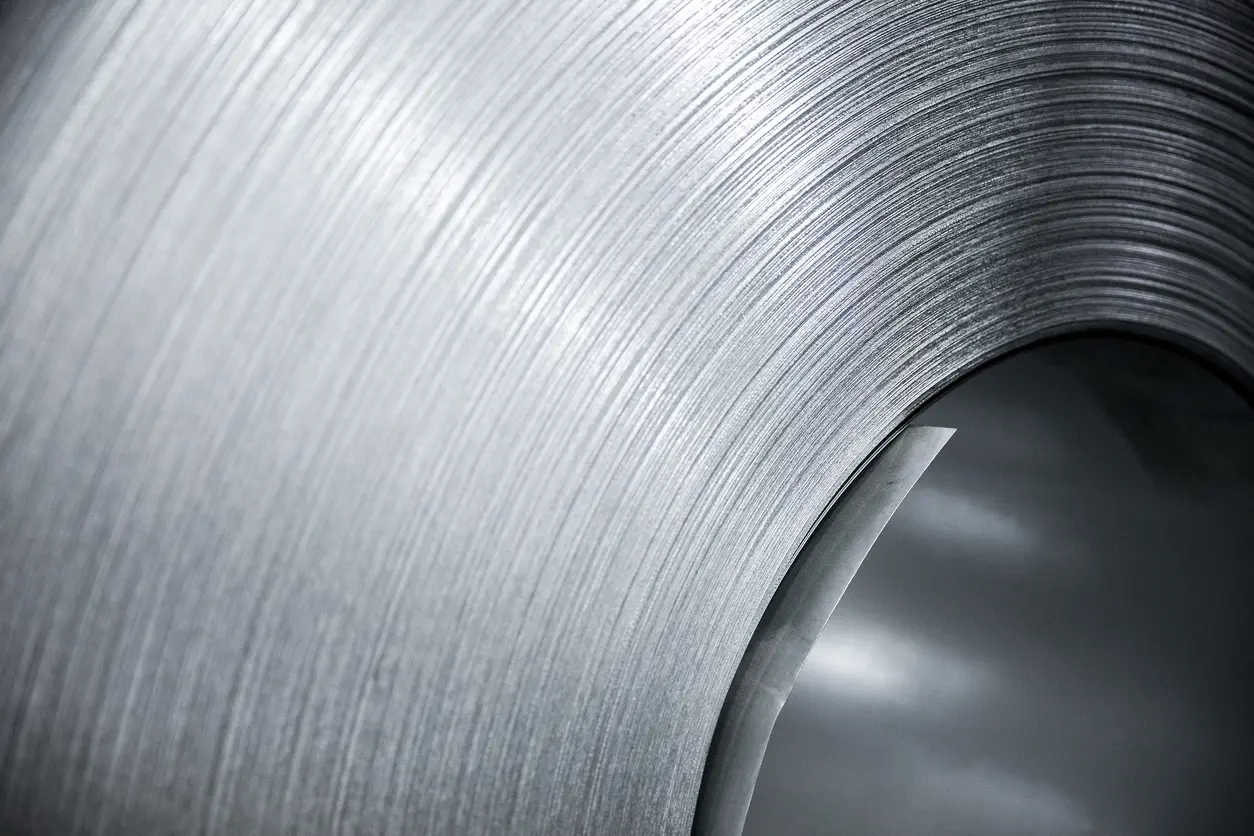

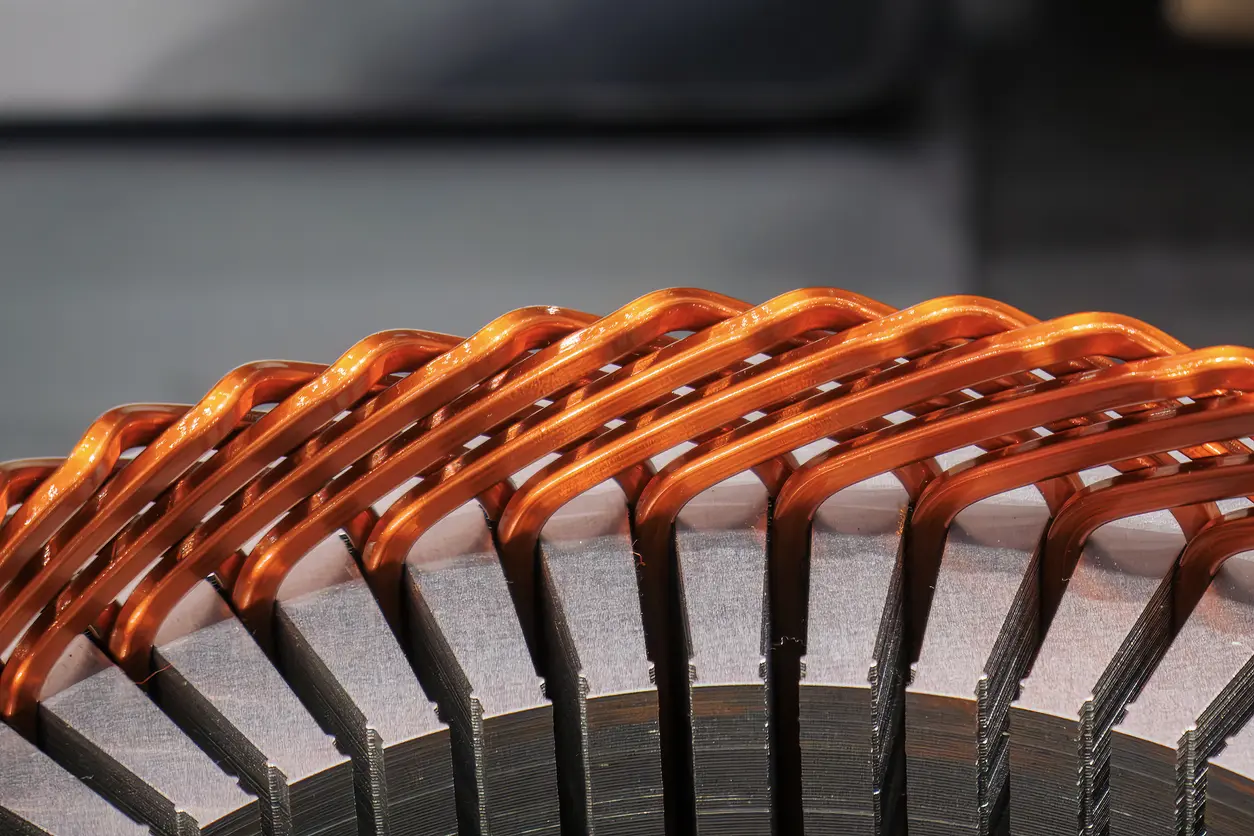

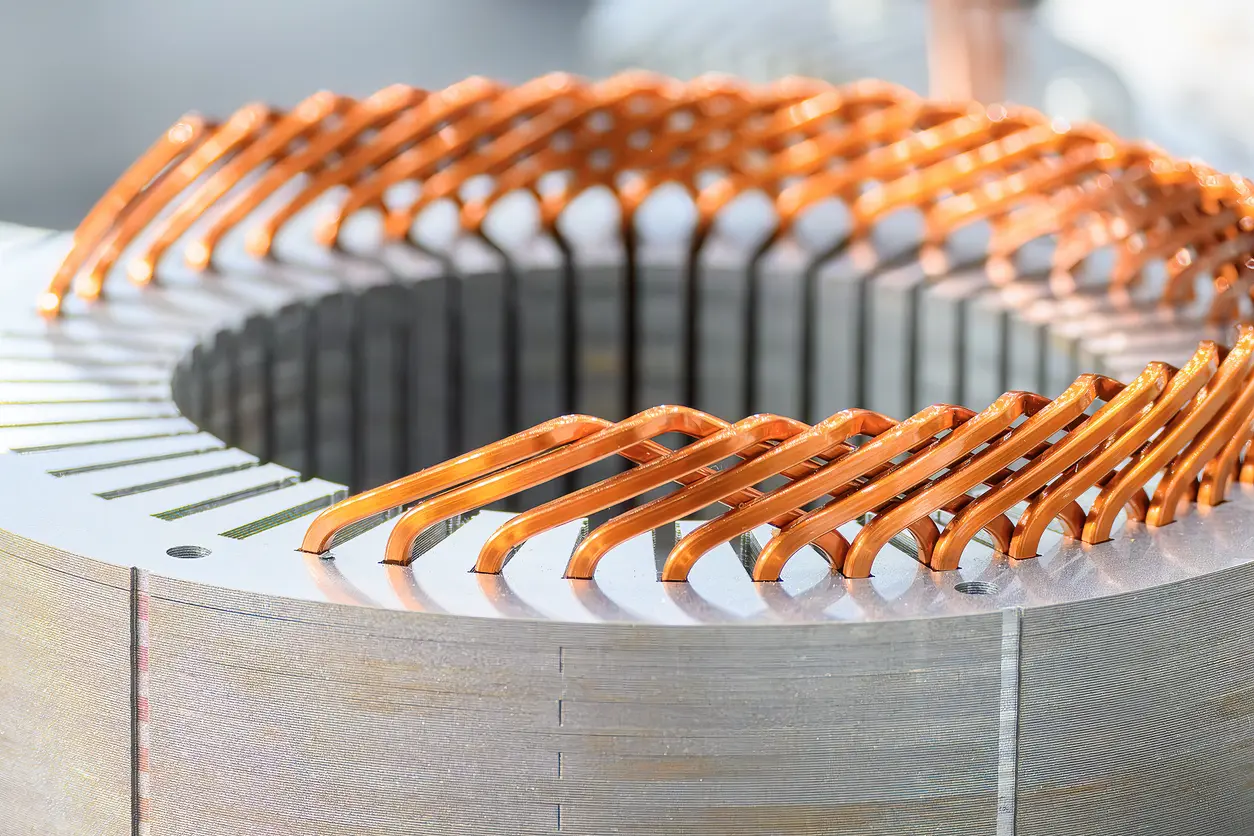

Stator core laminations are thin steel sheets stacked together to form part of the EV motor core. They are usually made of materials like silicon steel, chosen for their magnetic properties and ability to minimize energy losses. These laminations are insulated from one another to prevent the flow of eddy currents, which can otherwise lead to unnecessary heat and energy waste.

The primary role of stator core laminations is to generate and support the magnetic fields required for motor operation. They house the stator windings, which interact with the rotor to convert electrical energy into mechanical energy. The precision in their design and material choice directly impacts the motor’s overall efficiency.

2.2 The Role of EV Motor Cores

The EV motor core, of which stator core laminations are an integral part, is responsible for converting electrical energy into mechanical power to drive the vehicle. High-quality laminations reduce energy losses, enhance the motor’s efficiency, and extend its operational lifespan. This is particularly important for EVs, where optimizing energy use can significantly extend driving range and reduce the frequency of charging.

3. Impact of Stator Core Laminations on EV Performance

3.1 Key Factors for Motor Efficiency

Stator core laminations are essential for improving motor efficiency in EVs. A well-designed lamination can reduce both eddy current and hysteresis losses. These losses occur when electric fields generate unwanted circulating currents and when magnetic materials fail to align perfectly with the fields. By selecting high-grade materials and optimizing the lamination thickness, engineers can minimize these inefficiencies.

Another factor that affects motor performance is heat generation. Inefficient motors tend to run hotter, which can lead to damage and reduced efficiency. Laminations help manage heat flow, dissipating excess heat effectively and ensuring that the motor remains cool under operation.

3.2 Reducing Energy Losses

Eddy current and hysteresis losses are major contributors to energy inefficiency in motors. Eddy currents are induced when conductors are exposed to changing magnetic fields, while hysteresis losses result from the lag in magnetic field changes within the material. Stator core laminations combat these losses by breaking up the paths for circulating currents and using materials with low hysteresis. This not only improves efficiency but also prevents the motor from overheating.

In high-performance EVs, where motors operate at high speeds and power densities, advanced materials like thin-gauge silicon steel laminations are used to further reduce losses. These materials offer a balance between mechanical strength and magnetic properties, ensuring optimal motor performance.

4. The Environmental and Economic Benefits

4.1 Enhancing Energy Efficiency

By using advanced stator core laminations, EV manufacturers can improve the energy efficiency of their vehicles. Efficient motors use less electrical energy to produce the same amount of mechanical energy, leading to longer battery life and extended driving ranges. This is a critical factor for consumers, who prioritize vehicles with longer ranges and lower running costs.

4.2 Environmental Advantages

Efficient EV motors not only save energy but also contribute to environmental protection by reducing carbon emissions. As more consumers adopt EVs, the collective reduction in emissions will significantly impact global efforts to combat climate change. Moreover, efficient motors mean fewer resources are consumed during operation, contributing to the overall sustainability of electric vehicles.

5. Future of Stator Core Lamination Technology

5.1 Research and Development in New Materials

Ongoing developments in materials aim to enhance the efficiency of stator core laminations. Innovations in steel compositions can offer lower losses, better magnetic permeability, and higher thermal conductivity. These improvements have the potential to make motors smaller, lighter, and more powerful, which is particularly beneficial for compact EV designs.

Advancements in bonding techniques, such as self-bonding lamination stacks, are also being explored to reduce losses and improve the structural integrity of the motor core. These developments in materials and processes are expected to contribute to improvements in EV motor efficiency in the future

5.2 Automation and Manufacturing Processes

Automation is revolutionizing the production of stator core laminations. Automated lines allow for precise assembly of thin, high-quality laminations, reducing manufacturing errors and defects. This leads to more consistent product quality and lower production costs, making EVs more affordable for consumers.

New manufacturing techniques, such as laser cutting and bonding varnishes, are also making it easier to produce efficient and durable laminations. These techniques allow for greater design flexibility and enable manufacturers to meet the growing demand for high-performance EV motors.

6. Case Studies: Leading EV Manufacturers

6.1 Tesla’s Motor Design

Tesla, a leader in the EV market, has invested heavily in advanced motor technologies. Tesla’s motors are known for their high efficiency and use of cutting-edge stator core lamination technology. The company uses high-grade silicon steel laminations, which reduce energy losses and improve driving range. Tesla’s success in motor design has been a significant factor in its market dominance and has set the standard for other manufacturers to follow.

6.2 Other Successful EV Brands

Other major EV manufacturers, including Nissan and BMW, have also adopted advanced stator core lamination technologies. For example, the Nissan Leaf and BMW i3 both use efficient laminations to improve motor performance and reduce energy losses. These brands continuously innovate, improving motor design and production processes to stay competitive in the rapidly evolving EV market.

Conclusion

As a core component of EV motors, the stator core lamination plays a vital role in improving the performance and efficiency of electric vehicles. Through continuous advancements in materials and manufacturing processes, stator core lamination technology is expected to further drive the growth of the EV market, offering more energy-efficient, environmentally friendly transportation solutions.

If you need high-quality stator core laminations or other EV motor core components, feel free to contact us. Our dedicated team of experts is ready to provide the best solutions for your needs.

For more in-depth information on motor lamination technology, visit this page discussing on motor manufacturing techniques.