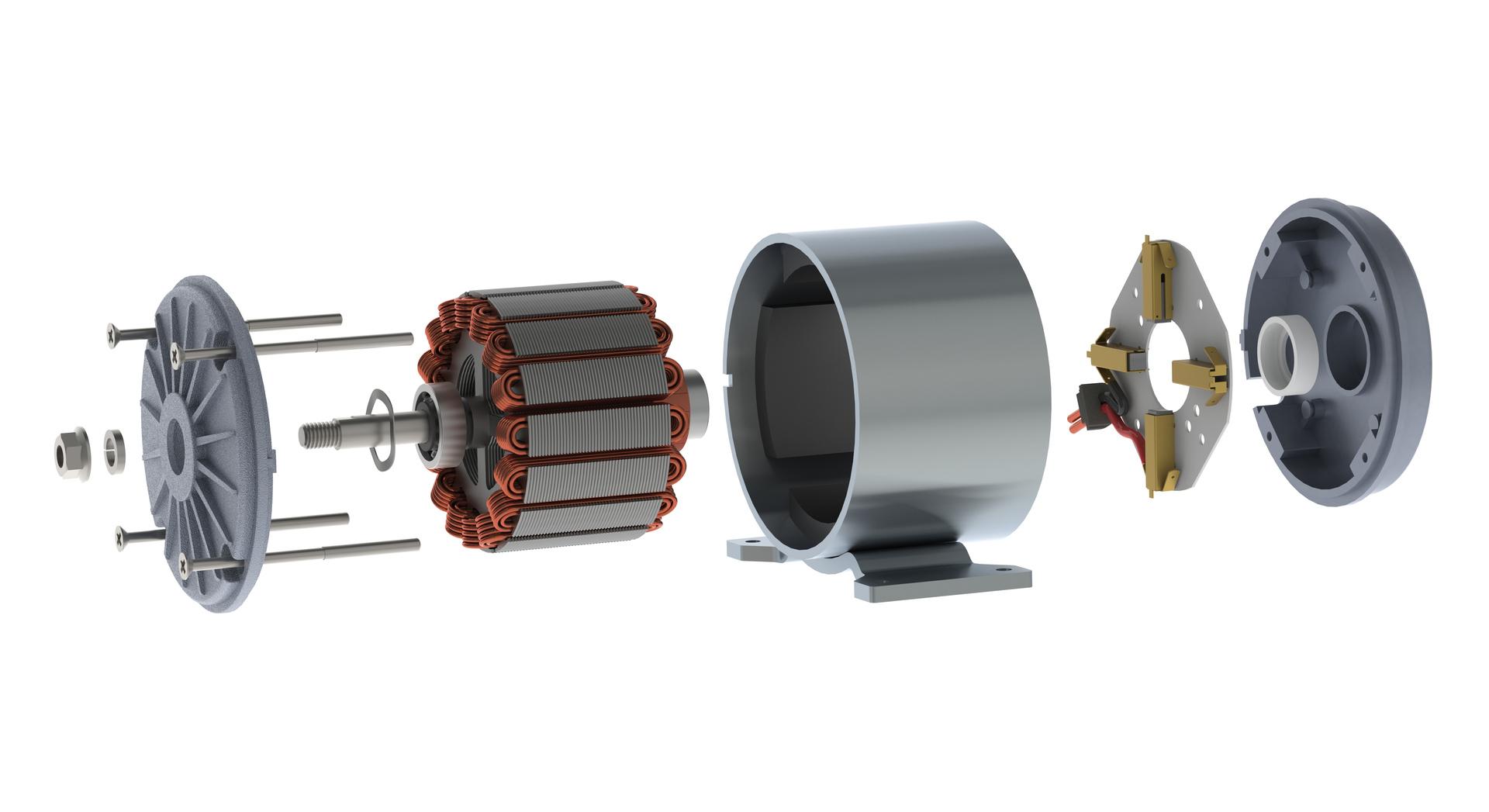

Our skilled consultants collaborate closely with you to transform your vision into a functional prototype motor core. We leverage deep industry knowledge to optimize design, performance, and efficiency.

At Yucca, we offer access to a range of versatile manufacturing solutions to bring your motor core prototypes to life and

support low-volume production runs:

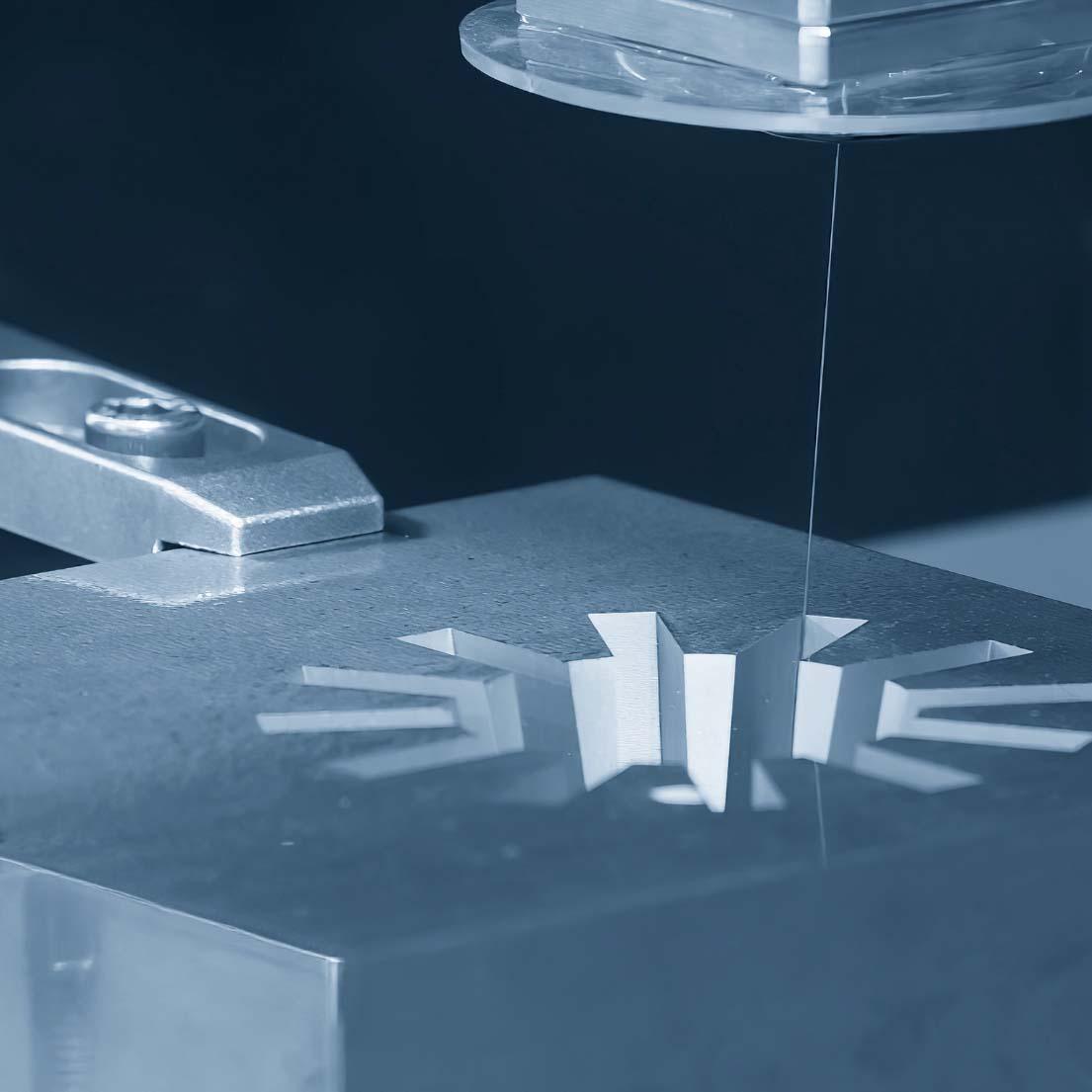

The advanced Wire EDM (Electrical Discharge Machining) technology allows us to cut intricate and complex shapes with exceptional precision, making it ideal for prototyping intricate motor core designs and

producing small batches of laminations.

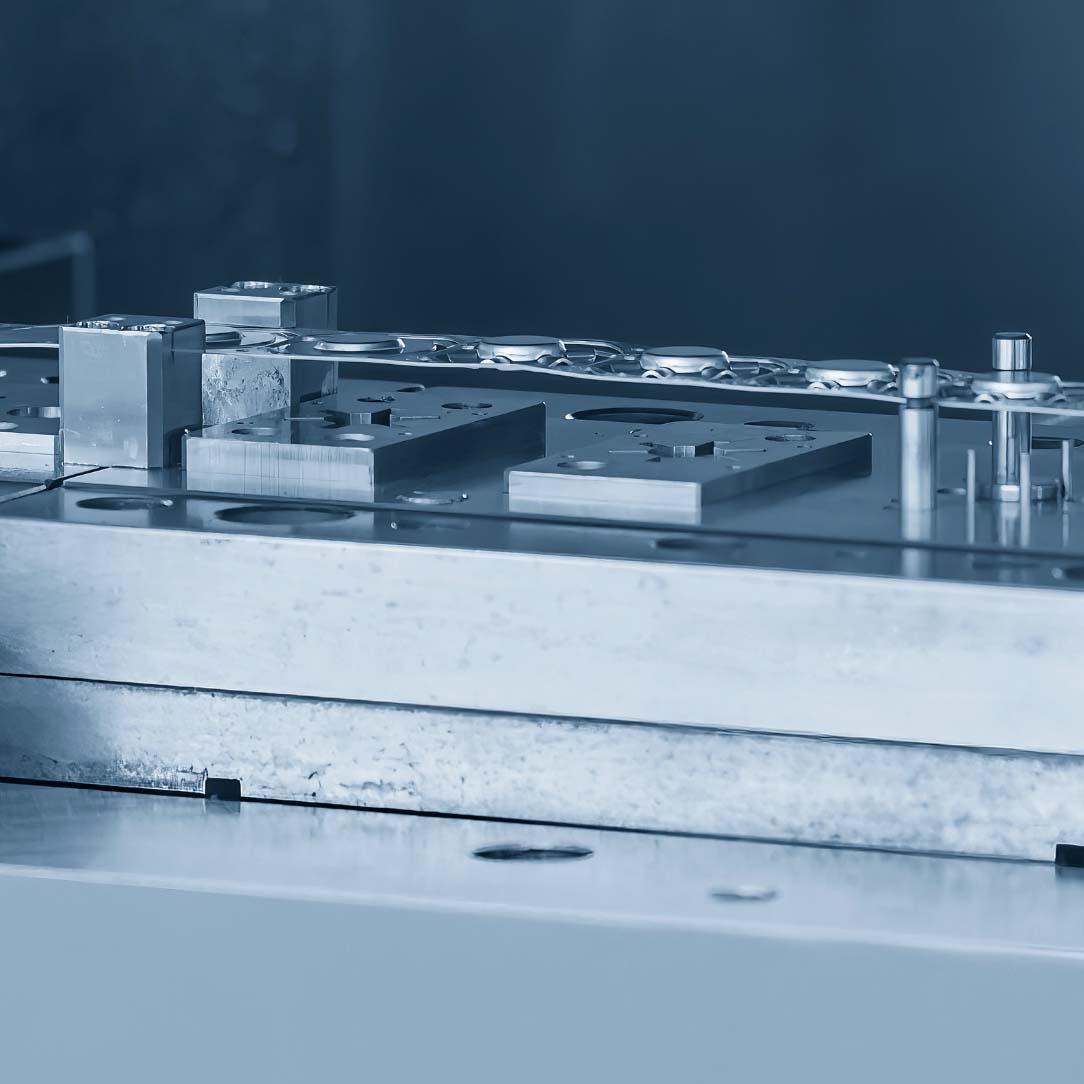

The simple die technology enables efficient and cost-effective production of motor cores lamination.

This method is perfect for low-volume manufacturing, ensuring consistent quality and quick for various

applications.

No matter the size or complexity of your project, Yucca’s versatile capabilities ensure your prototype motor core is delivered with accuracy, reflecting your exact design specifications.

Identify and address design flaws early, minimizing costly mistakes during full production.

Accelerate your product development cycle and gain a competitive edge.

Avoid expensive tooling modifications by refining your design through prototyping.

Yucca Manufacturing offers a comprehensive suite of prototype motor core services, guiding you through every stage of development, from concept to validation. Our commitment to quality, precision, and customer satisfaction ensures that your prototype motor core is built to the outstanding standards.