Transformer Core Laminations: Enhancing Efficiency and Reliability in Power Systems.

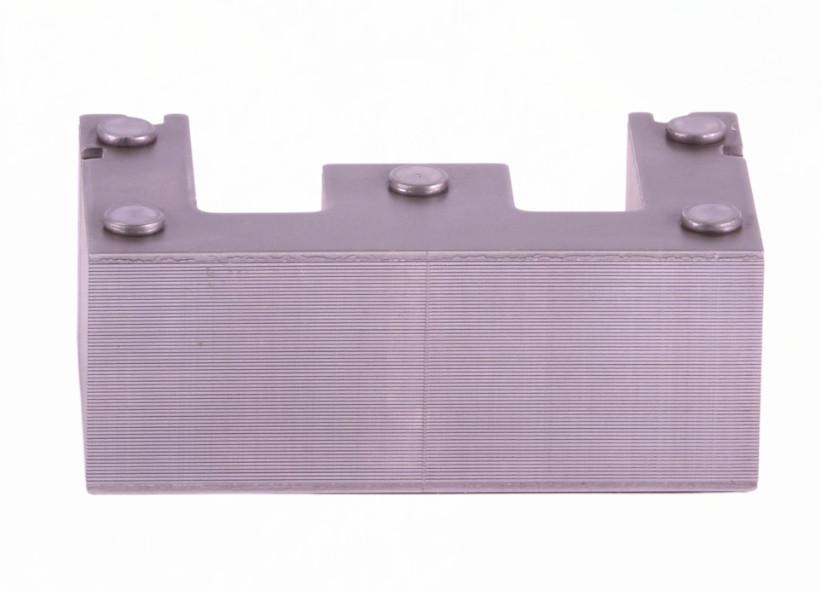

Yucca Manufacturing offers custom-engineered transformer core laminations, minimizing core losses and maximizing efficiency for your power distribution, industrial, and

renewable energy applications and more.

With over half a century of experience in motor core design and lamination technology, Yucca Manufacturing strives to deliver innovative solutions for a wide range of industries.

Our team of consultants is dedicated to providing you with the most suitable material choices for laminations and electrical steel grades, maximizing your transformer’s efficiency, performance, and lifespan.

We offer access to stamping progressive die set up, simple die, and Wire EDM manufacturing methods for your transformer core lamination, tailoring our approach to each customer’s unique needs and specifications.

Utilizing inspection model from Keyence, we rigorously assess lamination products and provide product inspection reports, ensuring exceptional quality and reliability for your transformer applications.

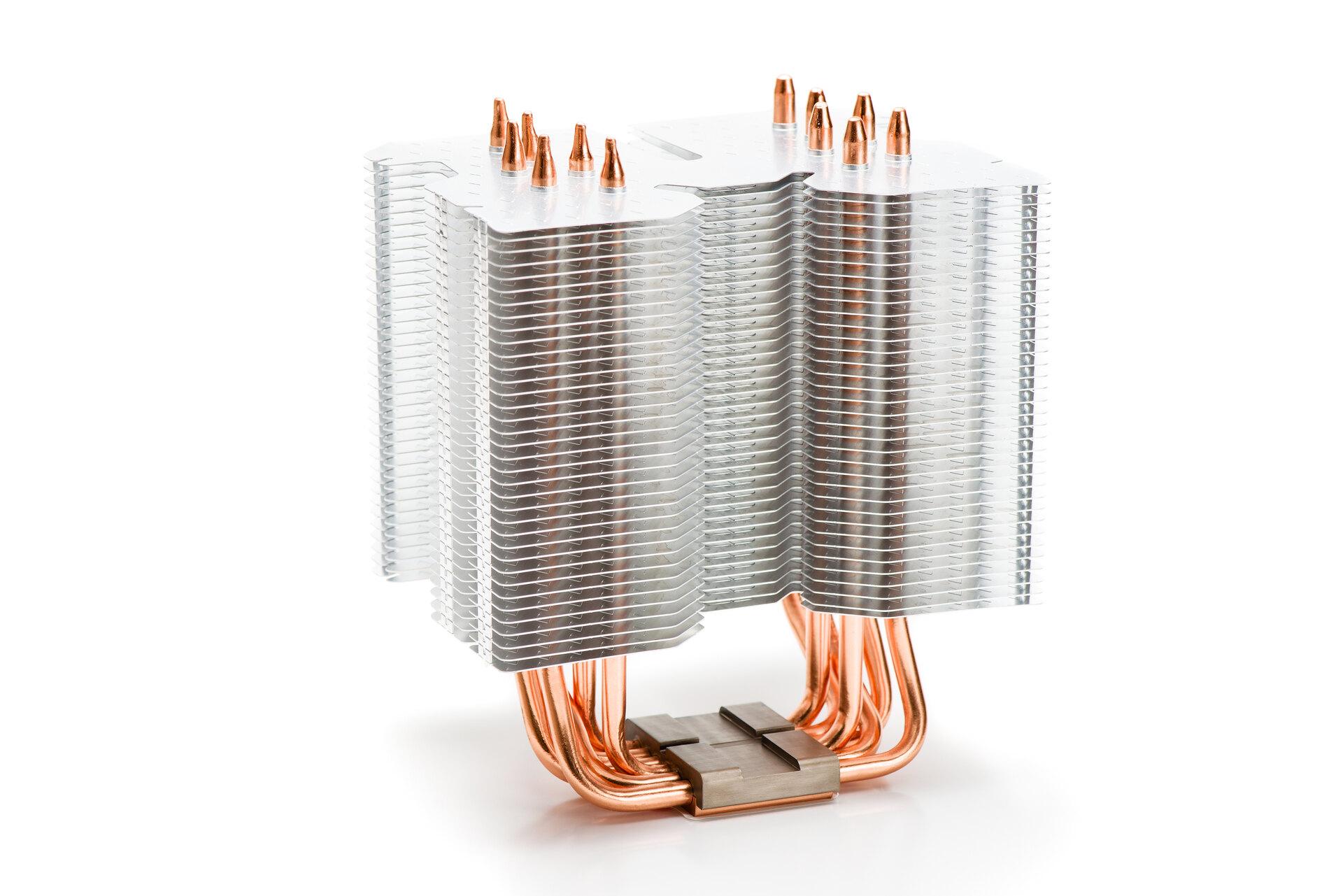

Superior heat dissipation for cooler, longer-lasting transformers based on your design and material selection.

Lower eddy current and hysteresis losses, enhancing overall efficiency.

Optimized performance with minimal energy wastage, reducing operational costs.

Quieter operation due to high quality lamination core and design.

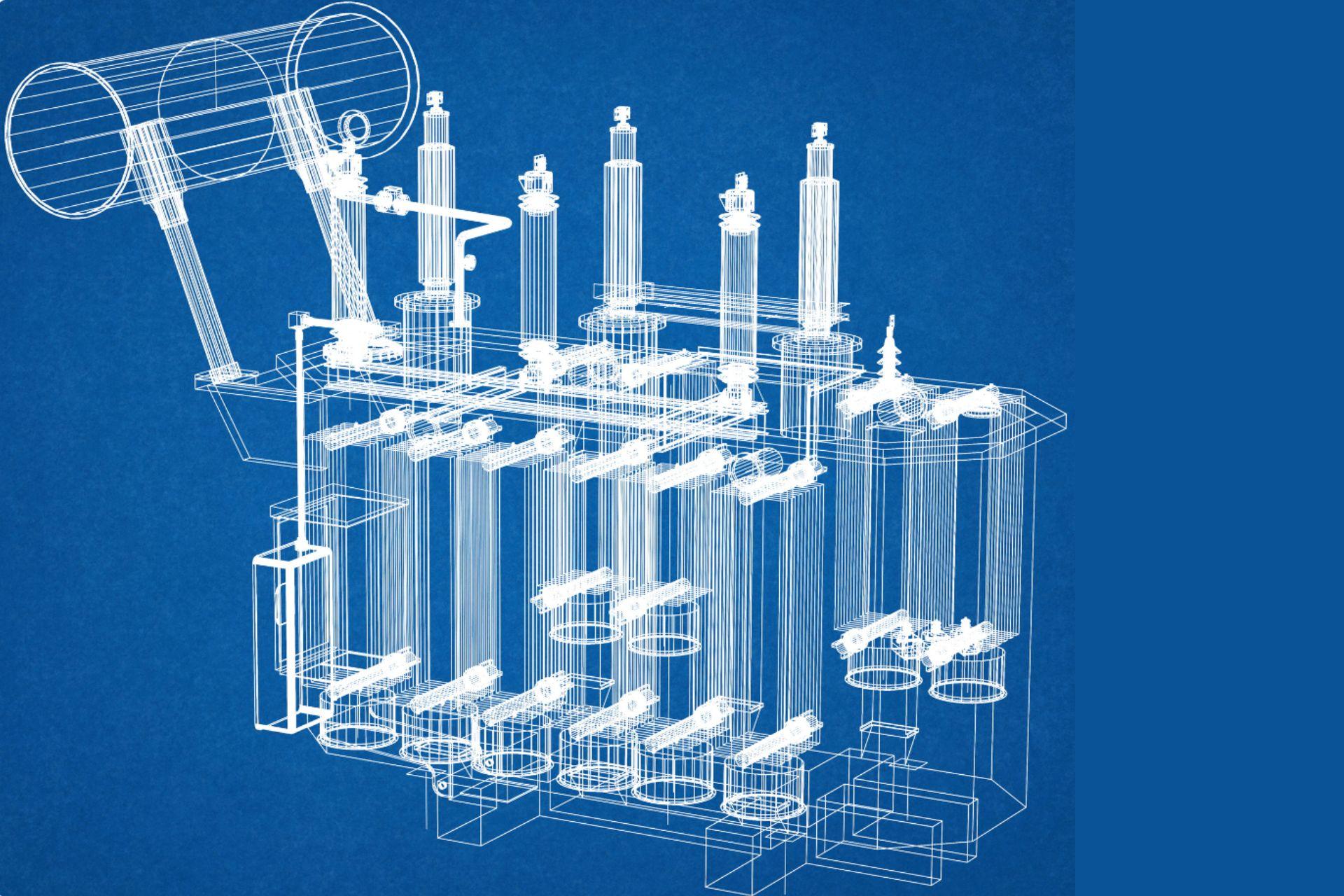

Essential for power transformers used in transmitting electricity over long distances, supporting efficient distribution with minimal losses.

Employed in manufacturing plants, oil refineries, and chemical industries for voltage regulation and stable power supply, providing reliable and efficient operation in demanding industrial settings.

Utilized in wind farms, solar power plants, and hydroelectric stations to enable efficient energy conversion and transmission, supporting sustainable energy systems.

Used in transformer rectifiers for converting AC to DC in railways, trams, and electric vehicles, ensuring smooth power conversion and reliable operation, which is crucial for modern transportation infrastructure.

Found in devices like televisions, audio systems, and computer power supplies, providing necessary voltage requirements and ensuring efficient operation of various electronics.

Small transformers with ferrite cores are used in modems, routers, and telephones to efficiently transmit signals, maintaining reliable communication systems.