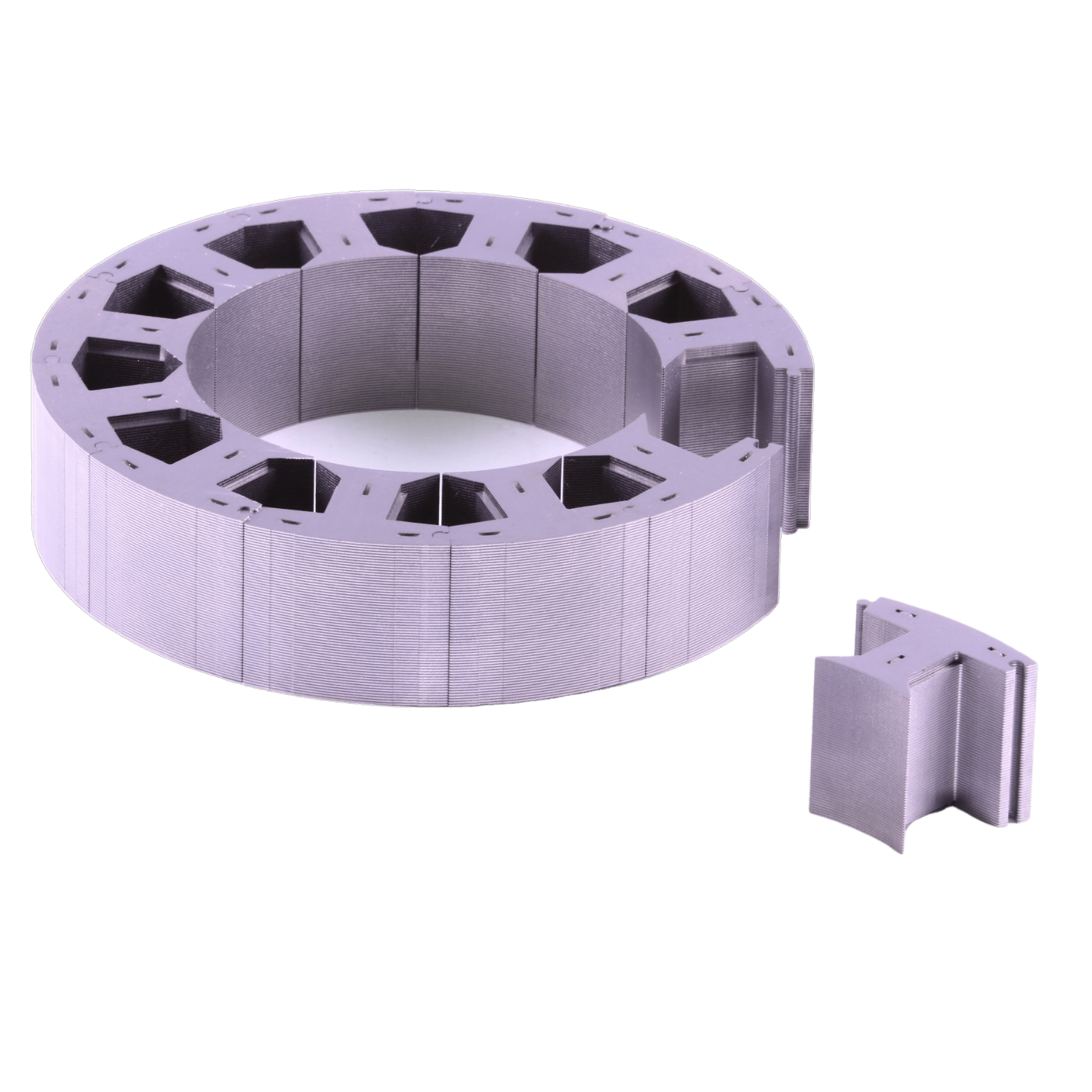

High-Efficiency Electric Motor Core Laminations:

Unleash Superior Performance and Savings.

Your Trusted Partner for High-Performance Motor Core Solutions

With half a century of experience in motor core design and lamination technology, Yucca Manufacturing strives to deliver innovative solutions for a wide range of industries.

Our consultants are here to assist if you’re unsure about material selection. We’ll help you choose the most suitable electrical steel grade to ensure optimal performance for your high-efficiency motor cores.

We offer access to stamping progressive die set-up, simple die, and Wire EDM manufacturing methods for your high-efficiency motor core lamination, tailoring our approach to each customer’s unique needs and specifications.

Utilizing inspection model from Keyence, we rigorously assess lamination products and provide product inspection reports, ensuring exceptional quality and reliability for your motor core applications.

High-efficiency motor cores are engineered to reduce eddy current and hysteresis losses, directly enhancing the overall efficiency of the motor.

A well-designed motor core enhances magnetic circuit efficiency, aiding better energy usage. However, power factor is also influenced by winding design and load.

Advanced materials and design in the motor core facilitate better heat dissipation, keeping the motor cooler and prolonging its lifespan.

Precision-engineered motor cores minimize magnetic flux imbalances, leading to smoother operation with reduced noise and vibration.

High-efficiency motor cores can be tailored to meet specific performance requirements, supporting the motor operates optimally for your unique application.

Pumps, fans, compressors, HVAC systems, manufacturing equipment.

Elevators, escalators, refrigeration units, building automation.

Ceiling fans, air conditioners, garage door openers, appliances

Increased range and performance for electric cars, buses, and trucks.

Optimized efficiency for wind turbines and solar power systems.

We utilize sustainable manufacturing practices and source materials responsibly to minimize waste and conserve resources

Yucca Manufacturing is dedicated to developing sustainable solutions that reduce energy consumption and minimize environmental impact. Our high-efficiency motor core laminations are a testament to this commitment.

Our high efficiency electric motor cores are designed to reduce core losses, resulting in significant energy savings over the lifespan of your motors. By choosing Yucca, you're not only investing in high-performance motors but also contributing to a more sustainable future.