High-Performance Electric Moped Motor Core

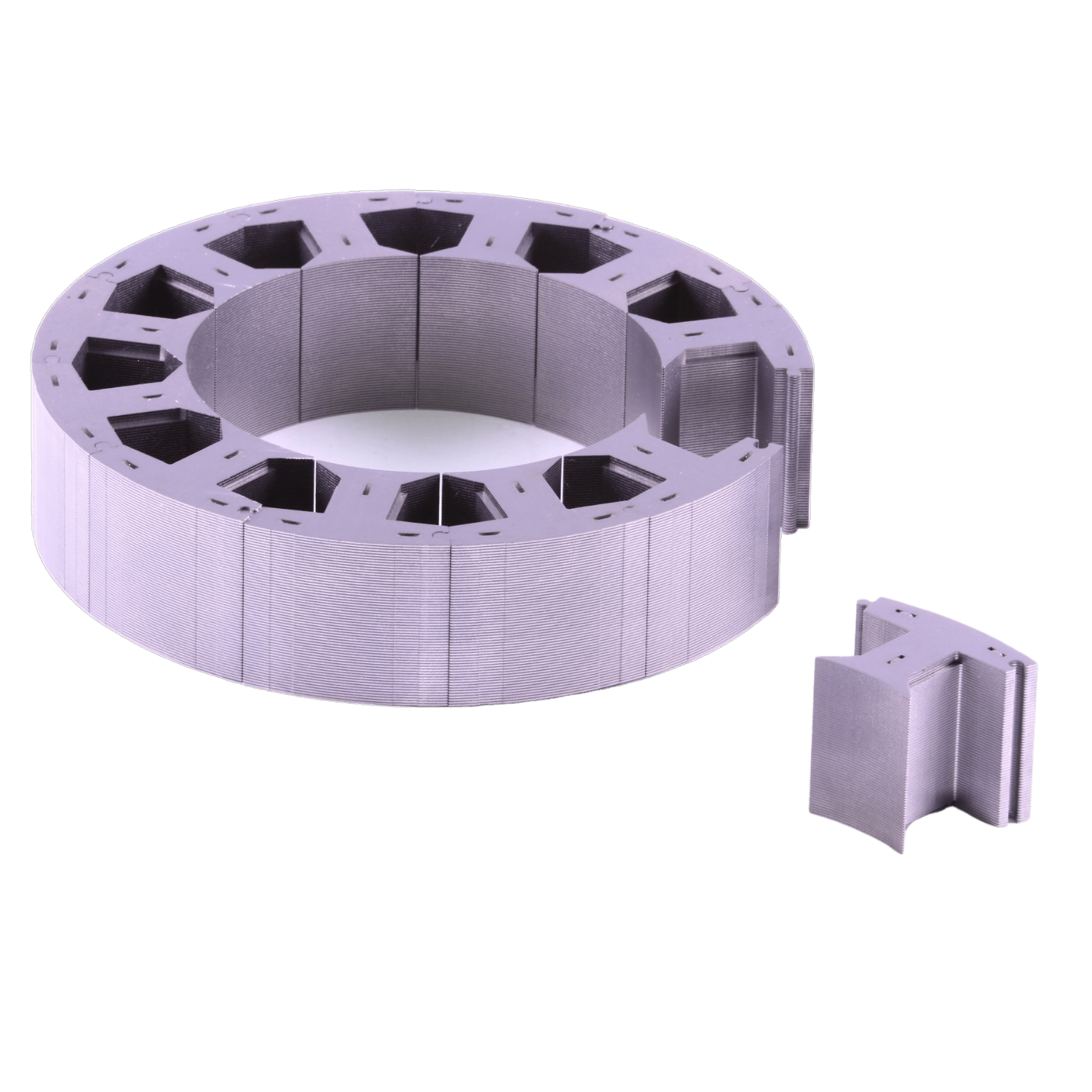

Laminations: Boost Range and Efficiency.

With over half a century of experience in motor core design and lamination technology, Yucca Manufacturing strives to deliver innovative solutions for the electric moped industry.

We’re dedicated to delivering precision-engineered electric moped motor core laminations that maximize efficiency, power density, and range for your electric mopeds.

Leveraging state-of-the-art manufacturing capabilities, we offer access to progressive die stamping, Wire EDM, and simple die methods, tailoring each solution to your unique specifications.

Yucca provides motor core laminations aimed to enhance moped performance, offering several key benefits.

Through our rigorous inspection process ensuring the quality of the laminations, our cores aim to minimize iron losses, helping to improve efficiency and contributing to extended range and lower energy consumption.

The lamination products we offer are designed for high power density, supporting compact motor designs that enable agile handling and responsive performance.

With a focus on effective thermal management, these exceptional laminations assist in heat dissipation by reducing the potential iron core loss.

We provide customizable solutions to meet a variety of moped motor core requirements, ensuring compatibility and optimal performance for different models and needs.

Our motor core design can meet your requirements and specific needs. From material selection to lamination thickness, we support efficient core performance with low iron loss, contributing to better thermal management.

Tailored designs to meet specific moped motor core requirements, ensuring optimal performance for various models and riding styles.

Reduced core losses for extended range and lower energy consumption.

Compact and lightweight designs for nimble handling and agile performance.

Minimized noise and vibration by the high quality lamination.