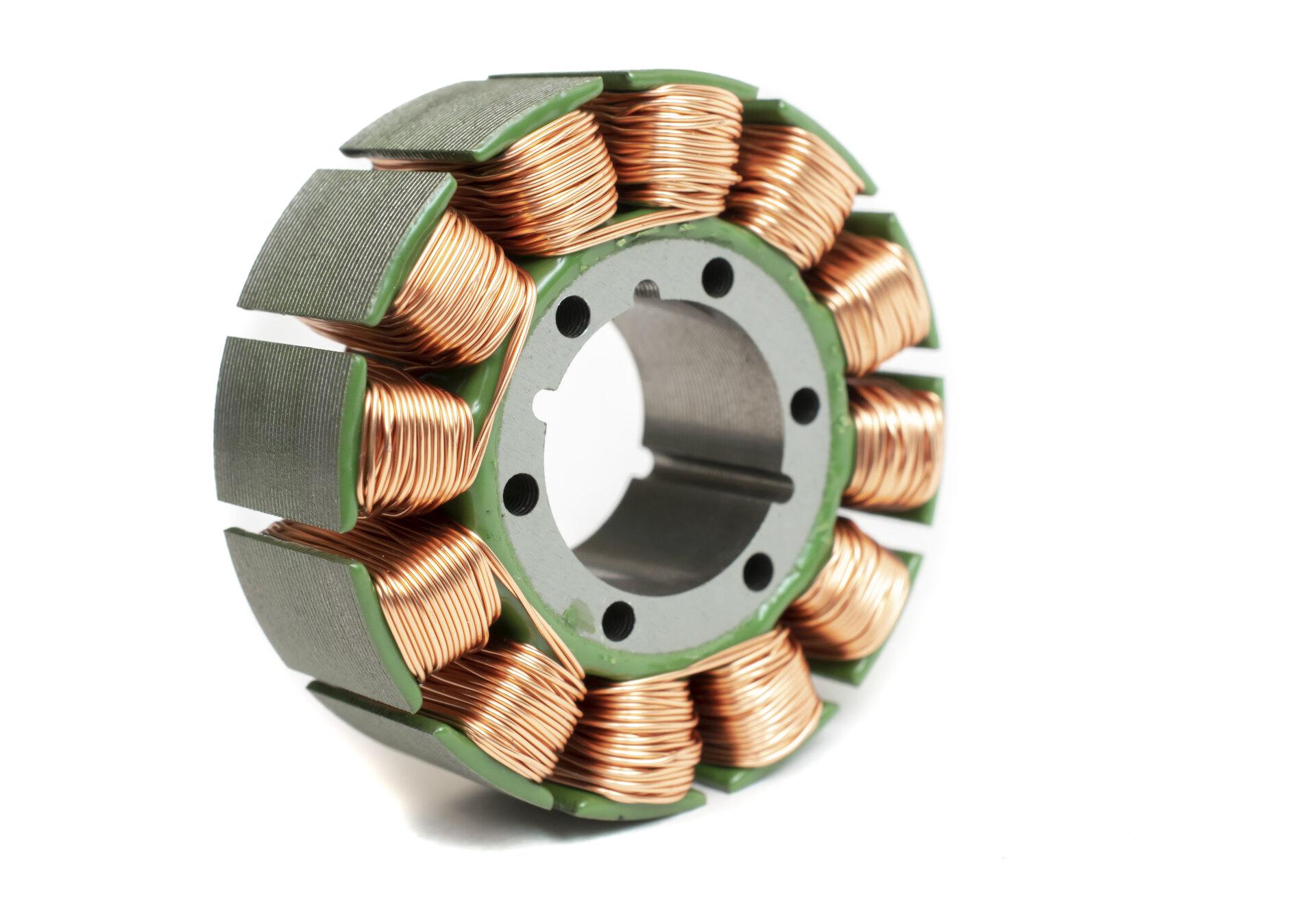

High-Performance Electric Drone Motor Rotor & Stator Cores: Extended Flight, Maximum Power.

The Core of Drone Performance: Benefits of Yucca’s Motor Cores

We have a specialized material type for drone motor core usage.

Core design focused on reducing energy losses to improve efficiency.

Balanced power density and weight for better agility and maneuverability.

Thermal management features help maintain consistent performance.

Motor cores can be tailored to fit different drone motor types and applications.

Engineered for smooth operation, supporting stability and minimizing wear.